Introduction to High TG PCB

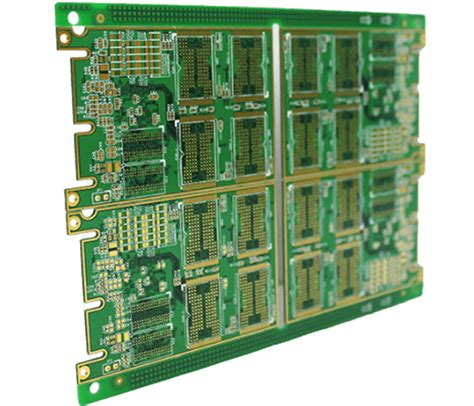

High TG PCB, also known as High Glass Transition Temperature PCB, is a type of printed circuit board that offers superior thermal stability and reliability compared to standard FR-4 PCBs. These PCBs are designed to withstand higher temperatures and more demanding operating conditions, making them ideal for applications in industries such as automotive, aerospace, and military.

What Does TG Mean in PCB?

In the context of PCBs, TG stands for Glass Transition Temperature. This is the temperature at which the PCB Substrate transitions from a rigid, glassy state to a softer, more flexible state. The higher the TG value, the more heat-resistant the PCB will be, and the better it will perform in high-temperature environments.

Advantages of High TG PCB

High TG PCBs offer several advantages over standard FR-4 PCBs:

- Enhanced thermal stability

- Improved reliability in harsh environments

- Reduced risk of delamination and warping

- Better signal integrity at higher temperatures

- Longer product life span

Types of High TG PCB materials

There are several types of high TG PCB materials available, each with its own unique properties and benefits.

1. Polyimide (PI)

Polyimide is a high-performance polymer that offers excellent thermal stability, with a TG of up to 260°C. It also has good chemical resistance and low moisture absorption. PI PCBs are commonly used in aerospace, military, and high-temperature applications.

2. High Tg FR-4

High Tg FR-4 is an enhanced version of the standard FR-4 material, with a TG of 170°C to 180°C. This material offers improved thermal stability and reliability compared to standard FR-4, while still being cost-effective. High Tg FR-4 PCBs are suitable for automotive and industrial applications.

3. Bismaleimide Triazine (BT)

BT is a high-performance thermoset polymer with a TG of up to 210°C. It offers excellent electrical properties, low moisture absorption, and good dimensional stability. BT PCBs are often used in high-frequency and high-speed applications, such as telecommunications and networking equipment.

Comparison of High TG PCB Materials

| Material | Glass Transition Temperature (TG) | Key Features |

|---|---|---|

| Polyimide (PI) | Up to 260°C | Excellent thermal stability, chemical resistance |

| High Tg FR-4 | 170°C to 180°C | Enhanced thermal stability, cost-effective |

| BT | Up to 210°C | Excellent electrical properties, low moisture absorption |

Manufacturing Process of High TG PCB

The manufacturing process for high TG PCBs is similar to that of standard PCBs, with a few key differences to accommodate the unique properties of the high TG materials.

1. Material Selection

The first step in manufacturing a high TG PCB is to select the appropriate material based on the specific requirements of the application, such as the operating temperature range, electrical properties, and mechanical stability.

2. PCB Design

The PCB design process involves creating the circuit layout, selecting the appropriate components, and ensuring that the design meets the required specifications. High TG PCBs may require special design considerations to account for the unique properties of the materials used.

3. Lamination

During the lamination process, the PCB layers are stacked and pressed together under high temperature and pressure to form a solid board. High TG materials may require higher lamination temperatures and pressures compared to standard FR-4.

4. Drilling and Plating

After lamination, the PCB is drilled to create the necessary holes for components and vias. The holes are then plated with a conductive material, typically copper, to establish electrical connections between layers.

5. Etching and Solder Mask Application

The unwanted copper is etched away, leaving only the desired circuit patterns. A solder mask is then applied to protect the copper traces and prevent short circuits.

6. Surface Finishing

The final step in the manufacturing process is to apply a surface finish to the PCB to protect the copper traces and improve solderability. Common surface finishes for high TG PCBs include ENIG (Electroless Nickel Immersion Gold) and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold).

Applications of High TG PCB

High TG PCBs are used in a wide range of applications where thermal stability, reliability, and performance are critical.

1. Automotive Electronics

High TG PCBs are increasingly used in automotive electronics, particularly in under-hood applications where temperatures can reach up to 150°C. Examples include engine control units, transmission control modules, and power inverters for electric vehicles.

2. Aerospace and Military

Aerospace and military applications often require PCBs that can withstand extreme temperatures, vibrations, and shock. High TG PCBs, especially those made with polyimide, are well-suited for these demanding environments.

3. Industrial Equipment

Industrial equipment, such as power supplies, motor drives, and HVAC systems, can benefit from the improved thermal stability and reliability of high TG PCBs. These PCBs can help extend the life span of the equipment and reduce maintenance costs.

4. Telecommunications and Networking

High-speed telecommunications and networking equipment require PCBs with excellent electrical properties and signal integrity. High TG materials like BT can help minimize signal loss and distortion at higher frequencies and temperatures.

Challenges and Considerations for High TG PCB

While high TG PCBs offer numerous benefits, there are also some challenges and considerations to keep in mind when using these materials.

1. Cost

High TG materials are generally more expensive than standard FR-4, which can increase the overall cost of the PCB. However, the improved performance and reliability of high TG PCBs can often justify the higher initial cost.

2. Manufacturing Complexity

Manufacturing high TG PCBs may require specialized equipment and processes to handle the unique properties of the materials. This can increase the complexity and lead time of the manufacturing process.

3. Design Considerations

Designing high TG PCBs may require special considerations to account for the different thermal expansion rates and mechanical properties of the materials. Designers must ensure that the PCB layout and component selection are optimized for the specific high TG material being used.

Future Trends in High TG PCB Technology

As the demand for high-performance electronics continues to grow, the development of new high TG PCB materials and technologies is expected to accelerate.

1. Advanced Materials

Researchers are exploring new high TG materials, such as liquid crystal polymers (LCPs) and polyphenylene sulfide (PPS), which offer even higher thermal stability and performance compared to existing materials.

2. Embedded Components

Embedding components within the PCB substrate can help reduce the overall size and weight of the PCB while improving signal integrity and thermal management. High TG materials are well-suited for embedded component applications due to their excellent thermal stability and reliability.

3. 3D Printing

3D printing technology is being adapted for PCB manufacturing, enabling the creation of complex, three-dimensional PCB structures. High TG materials may play a key role in enabling 3D-printed PCBs for high-temperature and high-performance applications.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between high TG PCB and standard FR-4 PCB?

A: High TG PCBs offer better thermal stability and reliability compared to standard FR-4 PCBs. They can withstand higher temperatures and more demanding operating conditions, making them suitable for applications in industries such as automotive, aerospace, and military. -

Q: What is the glass transition temperature (TG) of high TG PCB materials?

A: The glass transition temperature (TG) of high TG PCB materials varies depending on the specific material. Polyimide (PI) has a TG of up to 260°C, High Tg FR-4 has a TG of 170°C to 180°C, and Bismaleimide Triazine (BT) has a TG of up to 210°C. -

Q: Are high TG PCBs more expensive than standard FR-4 PCBs?

A: Yes, high TG materials are generally more expensive than standard FR-4, which can increase the overall cost of the PCB. However, the improved performance and reliability of high TG PCBs can often justify the higher initial cost. -

Q: What are some common applications for high TG PCBs?

A: High TG PCBs are commonly used in automotive electronics, aerospace and military applications, industrial equipment, and telecommunications and networking equipment, where thermal stability, reliability, and performance are critical. -

Q: Are there any special design considerations when using high TG PCBs?

A: Yes, designing high TG PCBs may require special considerations to account for the different thermal expansion rates and mechanical properties of the materials. Designers must ensure that the PCB layout and component selection are optimized for the specific high TG material being used.

Conclusion

High TG PCBs offer superior thermal stability, reliability, and performance compared to standard FR-4 PCBs, making them an essential component in a wide range of high-temperature and demanding applications. As the electronics industry continues to push the boundaries of performance and functionality, the development of new high TG materials and technologies will play a crucial role in enabling the next generation of advanced electronic systems.

By understanding the properties, manufacturing processes, and applications of high TG PCBs, engineers and designers can make informed decisions when selecting materials and designing PCBs for their specific needs. As the demand for high-performance electronics grows, the importance of high TG PCBs will only continue to increase, driving innovation and shaping the future of the electronics industry.

Leave a Reply