Introduction to Axial Flux BLDC Motors

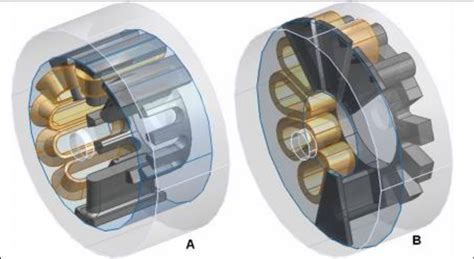

Axial Flux Brushless DC (BLDC) motors are a type of electric motor that has gained popularity in recent years due to their high efficiency, compact size, and high power density. Unlike traditional radial flux motors, where the magnetic flux is perpendicular to the motor’s axis of rotation, axial flux motors have their magnetic flux parallel to the axis of rotation. This unique design allows for a more compact and efficient motor, making them suitable for various applications, such as electric vehicles, robotics, and industrial automation.

Advantages of Axial Flux BLDC Motors

- High power density

- Compact size

- High efficiency

- Low noise and vibration

- Suitable for direct drive applications

Stator Design in Axial Flux BLDC Motors

The stator is a critical component of an axial flux BLDC motor, as it is responsible for generating the magnetic field that interacts with the rotor’s permanent magnets to produce torque. In this section, we will discuss the various aspects of stator design in axial flux BLDC motors.

Stator Core Materials

The stator core is typically made of laminated electrical steel to reduce eddy current losses and improve the motor’s efficiency. The choice of lamination material and thickness depends on the motor’s operating frequency and power rating.

| Material | Thickness (mm) | Power Rating (kW) | Frequency (Hz) |

|---|---|---|---|

| M19 | 0.35 | 1-10 | 50-400 |

| M15 | 0.25 | 0.1-1 | 400-1000 |

| Amorphous | 0.025 | 0.01-0.1 | 1000-10000 |

Winding Configuration

The winding configuration plays a crucial role in determining the motor’s performance characteristics, such as torque, speed, and efficiency. There are two main types of winding configurations used in axial flux BLDC motors:

- Concentrated Windings

- Simple construction

- High slot fill factor

-

Suitable for high-speed applications

-

Distributed Windings

- Reduced harmonic content

- Smoother torque profile

- Suitable for low-speed, high-torque applications

Comparison of Winding Configurations

| Parameter | Concentrated Windings | Distributed Windings |

|---|---|---|

| Torque Density | High | Moderate |

| Efficiency | Moderate | High |

| Harmonic Content | High | Low |

| Manufacturing Cost | Low | High |

Slot and Pole Combinations

The choice of slot and pole combinations affects the motor’s performance, torque ripple, and cogging torque. Some common slot and pole combinations for axial flux BLDC motors include:

- 12 slots, 8 poles

- 18 slots, 12 poles

- 24 slots, 16 poles

The selection of the appropriate slot and pole combination depends on the desired motor characteristics and the application requirements.

Thermal Management in Axial Flux BLDC Stators

Effective thermal management is essential for ensuring the reliable operation and longevity of axial flux BLDC motors. The stator is a significant source of heat generation due to copper losses in the windings and iron losses in the core.

Cooling Methods

- Natural Convection

- Suitable for low-power motors

-

No additional components required

-

Forced Air Cooling

- Suitable for medium-power motors

-

Requires a fan or blower

-

Liquid Cooling

- Suitable for high-power motors

- Requires a cooling jacket and a liquid circulation system

Comparison of Cooling Methods

| Method | Power Range (kW) | Complexity | Cost |

|---|---|---|---|

| Natural Convection | 0.1-1 | Low | Low |

| Forced Air Cooling | 1-10 | Moderate | Moderate |

| Liquid Cooling | 10-100 | High | High |

Thermal Analysis Techniques

Thermal analysis is crucial for optimizing the stator design and ensuring proper heat dissipation. Some common thermal analysis techniques include:

- Lumped Parameter Thermal Network (LPTN)

- Simplified thermal model

-

Suitable for preliminary design and optimization

-

Finite Element Analysis (FEA)

- Detailed thermal model

- Suitable for final design validation and optimization

Manufacturing Considerations for Axial Flux BLDC Stators

The manufacturing process for axial flux BLDC stators involves several key steps, including lamination stamping, winding, insulation, and assembly.

Lamination Stamping

The stator core laminations are typically stamped from electrical steel sheets using a high-precision stamping die. The stamping process must ensure accurate dimensions and minimize burrs to maintain the motor’s performance and efficiency.

Winding Process

The winding process involves inserting the copper conductors into the stator slots and forming the desired winding configuration. There are two main winding methods used in axial flux BLDC motors:

- Hand Winding

- Suitable for low-volume production and prototyping

-

Allows for customization and flexibility

-

Machine Winding

- Suitable for high-volume production

- Ensures consistent quality and reduces manufacturing time

Insulation and Impregnation

Proper insulation and impregnation of the stator windings are essential for ensuring the motor’s reliability and longevity. The insulation system must withstand the motor’s operating temperature and voltage stress.

| Insulation Class | Temperature Rating (°C) | Common Materials |

|---|---|---|

| Class B | 130 | Polyester, Epoxy |

| Class F | 155 | Polyester, Epoxy |

| Class H | 180 | Polyimide, Silicone |

Vacuum Pressure Impregnation (VPI) is a widely used method for impregnating the stator windings with a suitable resin, such as epoxy or polyester. The VPI process ensures complete fill of the winding voids and enhances the insulation system’s thermal conductivity.

Testing and Quality Control

Rigorous testing and quality control procedures are essential for ensuring the performance and reliability of axial flux BLDC stators. Some common tests include:

- Insulation Resistance Test

- Measures the insulation system’s resistance to ground

-

Ensures the absence of insulation defects

-

Surge Test

- Detects turn-to-turn insulation failures

-

Ensures the winding’s integrity

-

Resistance Measurement

- Verifies the winding’s resistance

-

Ensures consistent quality and identifies any manufacturing defects

-

Thermal Imaging

- Identifies hot spots and uneven temperature distribution

- Helps optimize the stator design for better thermal management

Frequently Asked Questions (FAQ)

- What are the advantages of axial flux BLDC motors over radial flux motors?

-

Axial flux BLDC motors offer higher power density, compact size, and higher efficiency compared to radial flux motors. They are also suitable for direct drive applications, reducing the need for gearboxes and simplifying the overall system design.

-

How does the choice of stator core material affect the motor’s performance?

-

The choice of stator core material affects the motor’s efficiency, power density, and operating frequency. Laminated electrical steel, such as M19 and M15, is commonly used for low to medium frequency applications, while amorphous materials are suitable for high-frequency applications.

-

What are the differences between concentrated and distributed windings in axial flux BLDC stators?

-

Concentrated windings offer higher torque density and simpler construction but have higher harmonic content. Distributed windings provide a smoother torque profile and reduced harmonic content but are more complex to manufacture and have a lower slot fill factor.

-

How can thermal management be improved in axial flux BLDC stators?

-

Thermal management can be improved by selecting the appropriate cooling method (natural convection, forced air cooling, or liquid cooling) based on the motor’s power rating and application requirements. Proper thermal analysis using techniques like LPTN and FEA can help optimize the stator design for better heat dissipation.

-

What are the key manufacturing considerations for axial flux BLDC stators?

- The key manufacturing considerations for axial flux BLDC stators include lamination stamping, winding process, insulation, and impregnation. Ensuring accurate dimensions, consistent quality, and proper insulation and impregnation are essential for achieving the desired motor performance and reliability.

Conclusion

Axial flux permanent magnet BLDC stators are a critical component in the design and performance of axial flux BLDC motors. By understanding the various aspects of stator design, such as core materials, winding configurations, slot and pole combinations, and thermal management, engineers can optimize the motor’s performance and efficiency for specific applications.

Proper manufacturing processes, including lamination stamping, winding, insulation, and impregnation, are essential for ensuring the stator’s quality and reliability. Rigorous testing and quality control procedures help identify any defects and ensure consistent performance.

As the demand for high-performance, compact, and efficient electric motors continues to grow, axial flux BLDC motors and their optimized stator designs will play an increasingly important role in various industries, from electric vehicles to robotics and industrial automation.

Leave a Reply