What are Gold Edge Connectors?

Gold edge connectors are a type of electrical connector commonly used in printed circuit boards (PCBs) to establish a secure and reliable connection between different components or modules. These connectors feature a gold-plated surface on the edges, which provides several benefits over other materials. Gold is an excellent conductor of electricity and offers superior resistance to corrosion, making it an ideal choice for high-reliability applications.

Advantages of Gold Edge Connectors

- Corrosion Resistance: Gold is highly resistant to oxidation and corrosion, ensuring a stable connection even in harsh environments.

- High Conductivity: Gold is an excellent conductor of electricity, allowing for efficient signal transmission and minimizing power loss.

- Durability: Gold-plated connectors are more durable and have a longer lifespan compared to other materials, reducing the need for frequent replacements.

- Low Contact Resistance: The gold surface ensures low contact resistance, which is crucial for sensitive signals and high-speed data transmission.

- Compatibility: Gold edge connectors are compatible with a wide range of PCB materials and can be easily soldered or plugged into corresponding sockets.

Applications of Gold Edge Connectors

Gold edge connectors find applications in various industries and sectors where reliable and high-performance electrical connections are essential. Some of the key areas where these connectors are widely used include:

1. Consumer Electronics

In the consumer electronics industry, gold edge connectors are used in devices such as:

- Smartphones

- Tablets

- Laptops

- Digital Cameras

- Gaming Consoles

These connectors ensure stable connections between different components, such as memory cards, displays, and expansion modules.

2. Automotive Electronics

The automotive industry relies on gold edge connectors for critical applications, including:

- Engine Control Units (ECUs)

- Infotainment Systems

- Advanced Driver Assistance Systems (ADAS)

- Sensor Modules

- Power Management Systems

Gold edge connectors provide reliable connections in the harsh automotive environment, withstanding vibrations, temperature fluctuations, and exposure to moisture and chemicals.

3. Industrial Automation

Industrial automation systems require robust and reliable connectors to ensure smooth operation and minimize downtime. Gold edge connectors are used in:

- Programmable Logic Controllers (PLCs)

- Human-Machine Interfaces (HMIs)

- Industrial PCs

- Sensor and Actuator Modules

- Communication Interfaces

The gold-plated surface ensures reliable connections even in industrial settings with high levels of electromagnetic interference (EMI) and harsh environmental conditions.

4. Medical Devices

In the medical industry, gold edge connectors are used in various devices and equipment, such as:

- Patient Monitoring Systems

- Diagnostic Imaging Equipment

- Surgical Instruments

- Wearable Medical Devices

- Laboratory Analyzers

Gold edge connectors provide reliable and stable connections, ensuring the accuracy and integrity of critical medical data and signals.

5. Aerospace and Defense

Gold edge connectors are essential in aerospace and defense applications, where reliability and performance are paramount. These connectors are used in:

- Avionics Systems

- Radar and Communication Equipment

- Satellite Systems

- Military Vehicles

- Unmanned Aerial Vehicles (UAVs)

The gold-plated surface provides corrosion resistance and stable connections in extreme environments, including high altitudes, temperature variations, and exposure to radiation.

Types of Gold Edge Connectors

Gold edge connectors come in various types and configurations to suit different applications and PCB designs. Some common types of gold edge connectors include:

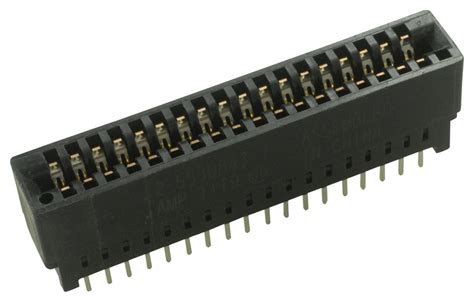

1. Card Edge Connectors

Card edge connectors are designed to directly connect with the exposed gold-plated edges of a PCB, eliminating the need for additional connectors on the board. These connectors are commonly used in expansion cards, memory modules, and daughterboards.

2. Board-to-Board Connectors

Board-to-board connectors are used to establish connections between two PCBs or modules. These connectors typically have gold-plated pins or contacts on both sides, allowing for a secure and reliable connection when the boards are mated together.

3. Micro Connectors

Micro connectors are miniaturized versions of gold edge connectors, designed for applications where space is limited. These connectors are commonly used in mobile devices, wearable electronics, and compact modules.

4. High-Speed Connectors

High-speed connectors are designed to support high data rates and frequencies, making them suitable for applications such as high-speed digital interfaces, video transmission, and high-bandwidth communication links. These connectors often feature gold-plated contacts to ensure signal integrity and minimize transmission losses.

5. Power Connectors

Power connectors are used to deliver electrical power to PCBs and modules. Gold-plated power connectors provide reliable and low-resistance connections, ensuring efficient power transfer and minimizing voltage drops.

Specifying Gold Edge Connectors

When selecting gold edge connectors for a specific application, several factors need to be considered to ensure optimal performance and compatibility. Some key specifications to consider include:

1. Pitch

The pitch refers to the distance between the center of one contact to the center of the adjacent contact. Common pitch sizes for gold edge connectors include:

- 0.5 mm

- 0.8 mm

- 1.0 mm

- 1.27 mm

- 2.54 mm

Choose the appropriate pitch based on the PCB design and the required contact density.

2. Number of Contacts

Gold edge connectors are available with different numbers of contacts, depending on the application requirements. Some common contact counts include:

- 10 contacts

- 20 contacts

- 30 contacts

- 40 contacts

- 50 contacts

- 60 contacts

- 100 contacts

Select the connector with the appropriate number of contacts to accommodate the necessary signals and power connections.

3. Contact Plating Thickness

The thickness of the gold plating on the connector contacts is an important consideration for durability and performance. Common gold plating thicknesses for edge connectors include:

- 15 microinches (0.38 µm)

- 30 microinches (0.76 µm)

- 50 microinches (1.27 µm)

Thicker gold plating provides better wear resistance and longer connector lifespan, but it also increases the cost.

4. Current Rating

The current rating of a gold edge connector indicates the maximum amount of current that can safely flow through each contact. Ensure that the selected connector has a current rating suitable for the application’s power requirements.

5. Mounting Type

Gold edge connectors can be mounted on the PCB using different methods, such as:

- Through-Hole Mounting

- Surface-Mount Technology (SMT)

- Press-Fit

Choose the mounting type that is compatible with the PCB manufacturing process and assembly requirements.

6. Environmental Considerations

Consider the environmental conditions in which the gold edge connector will be used, such as temperature range, humidity, vibration, and shock. Select connectors with appropriate ratings and certifications for the intended operating environment.

Best Practices for Using Gold Edge Connectors

To ensure optimal performance and reliability when using gold edge connectors, follow these best practices:

-

Proper PCB Design: Design the PCB with the appropriate edge connector footprint and ensure that the gold-plated contacts are properly aligned and spaced.

-

Handling and Storage: Handle gold edge connectors with care to avoid damage to the contacts. Store connectors in a clean, dry environment and use anti-static packaging when necessary.

-

Mating and Unmating: Follow the manufacturer’s guidelines for mating and unmating the connectors. Avoid excessive force or misalignment, which can cause damage to the contacts.

-

Soldering and Assembly: Use the appropriate soldering techniques and temperature profiles when attaching gold edge connectors to the PCB. Follow the manufacturer’s recommendations for solder type and flux.

-

Inspection and Testing: Perform visual inspections and functional tests to ensure proper connections and signal integrity. Use high-quality test equipment and follow industry standards for testing.

-

Maintenance and Cleaning: Regularly inspect and clean gold edge connectors to remove any contaminants or debris that may affect the connection quality. Use approved cleaning methods and solutions.

Troubleshooting Common Issues with Gold Edge Connectors

Despite their reliability and durability, gold edge connectors may sometimes encounter issues. Here are some common problems and troubleshooting tips:

1. Intermittent Connections

Intermittent connections can be caused by:

- Damaged or contaminated contacts

- Improper mating or alignment

- Loose or broken solder joints

To troubleshoot intermittent connections:

- Visually inspect the contacts for damage or contamination

- Check the mating alignment and ensure proper insertion

- Reflow or repair solder joints if necessary

2. High Contact Resistance

High contact resistance can result in signal degradation and power loss. Possible causes include:

- Oxidation or contamination on the contacts

- Insufficient contact pressure

- Wear or damage to the gold plating

To address high contact resistance:

- Clean the contacts using approved methods and solutions

- Check the contact pressure and adjust if necessary

- Replace the connector if the gold plating is worn or damaged

3. Signal Integrity Issues

Signal integrity problems, such as crosstalk, noise, or reflections, can occur due to:

- Improper PCB layout or routing

- Insufficient grounding or shielding

- Mismatched impedances

To resolve signal integrity issues:

- Review and optimize the PCB layout and routing

- Ensure proper grounding and shielding techniques are implemented

- Match the impedances of the connector and the PCB traces

FAQ

1. How does the gold plating thickness affect the performance of edge connectors?

The gold plating thickness on edge connectors influences their durability and performance. Thicker gold plating provides better wear resistance and a longer connector lifespan, as it can withstand more mating cycles and exposure to environmental factors. However, thicker gold plating also increases the cost of the connector. The choice of plating thickness depends on the specific application requirements, such as the expected number of mating cycles, environmental conditions, and budget constraints.

2. Can gold edge connectors be used in high-temperature environments?

Yes, gold edge connectors can be used in high-temperature environments, but it is essential to select connectors that are rated for the specific temperature range. High-temperature gold edge connectors are designed to withstand elevated temperatures without degrading the contact quality or reliability. These connectors often use specialized materials and plating processes to ensure stable performance in extreme conditions. When selecting a gold edge connector for high-temperature applications, review the manufacturer’s specifications and ensure that the connector meets the required temperature ratings.

3. How do gold edge connectors compare to other types of connectors in terms of cost?

Gold edge connectors are generally more expensive than connectors that use other plating materials, such as tin or nickel. The higher cost is primarily due to the use of gold, which is a precious metal with excellent electrical and chemical properties. However, the increased cost of gold edge connectors is often justified by their superior performance, reliability, and durability. In applications where high reliability and long-term stability are critical, the investment in gold edge connectors can lead to reduced maintenance costs and improved system performance over time.

4. Are gold edge connectors compatible with Lead-Free Soldering processes?

Yes, gold edge connectors are compatible with lead-free soldering processes. Lead-free soldering has become increasingly common due to environmental and health concerns associated with lead-based solders. Gold edge connectors can be soldered using lead-free solder alloys, such as tin-silver-copper (SAC) or tin-bismuth (SnBi) alloys. However, it is important to follow the manufacturer’s guidelines for lead-free soldering, as the process may require different temperature profiles and flux compared to traditional lead-based soldering. Proper soldering techniques and process control are essential to ensure reliable connections when using lead-free solders with gold edge connectors.

5. How often should gold edge connectors be inspected and cleaned?

The frequency of inspection and cleaning for gold edge connectors depends on the specific application and operating environment. In general, it is recommended to inspect and clean gold edge connectors periodically to ensure optimal performance and reliability. For connectors used in critical applications or harsh environments, more frequent inspections may be necessary. Visual inspections should be performed to check for signs of damage, wear, or contamination on the contacts. If contamination is detected, the connectors should be cleaned using approved methods and solutions, such as isopropyl alcohol or specialized contact cleaners. Regular maintenance helps prevent connection issues and extends the lifespan of the connectors.

Conclusion

Gold edge connectors are a reliable and high-performance solution for establishing electrical connections in a wide range of applications, from consumer electronics to industrial automation and aerospace systems. The gold-plated surface of these connectors provides excellent conductivity, corrosion resistance, and durability, ensuring stable and efficient signal transmission.

When selecting gold edge connectors, it is essential to consider factors such as pitch, number of contacts, plating thickness, current rating, and environmental requirements. Following best practices for PCB design, handling, soldering, and maintenance can help optimize the performance and reliability of these connectors.

By understanding the advantages, applications, and specifications of gold edge connectors, engineers and designers can make informed decisions when integrating these connectors into their projects. With proper selection, implementation, and maintenance, gold edge connectors can provide reliable and high-quality electrical connections in demanding applications.

Leave a Reply