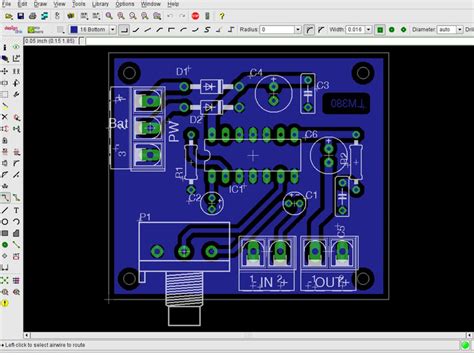

The Importance of CAD2CAM Integration in PCB Design and Manufacturing

The integration of CAD and CAM technologies has revolutionized the PCB industry, allowing for faster, more efficient, and cost-effective design and manufacturing processes. By seamlessly connecting the design phase with the manufacturing phase, CAD2CAM4PCB enables engineers to create high-quality PCBs with greater precision and reliability.

Benefits of CAD2CAM Integration

- Reduced time-to-market

- Improved design accuracy

- Enhanced manufacturability

- Cost savings through optimized processes

- Increased collaboration between design and manufacturing teams

Key Topics Covered at the CAD2CAM4PCB Seminar

The seminar covered a wide range of topics related to CAD2CAM4PCB, including:

1. Advanced PCB Design Techniques

Experts shared their insights on the latest PCB design techniques, such as high-speed design, signal integrity analysis, and thermal management. They emphasized the importance of considering manufacturability during the design phase to ensure smooth production and high-quality end products.

2. CAM Process Optimization

Attendees learned about the latest advancements in CAM technologies and how they can be leveraged to optimize the PCB manufacturing process. Topics included intelligent routing, automated optical inspection (AOI), and data preparation for manufacturing.

3. Industry 4.0 and Smart Manufacturing

The seminar also explored the impact of Industry 4.0 and smart manufacturing on the PCB industry. Speakers discussed the integration of advanced technologies, such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), into PCB design and manufacturing processes.

4. Sustainable PCB Manufacturing Practices

With the growing emphasis on environmental sustainability, the seminar dedicated a session to discuss sustainable PCB manufacturing practices. Attendees learned about eco-friendly materials, green manufacturing processes, and strategies for reducing waste and energy consumption.

Real-World Case Studies and Success Stories

One of the highlights of the CAD2CAM4PCB seminar was the presentation of real-world case studies and success stories. Industry leaders shared their experiences in implementing CAD2CAM4PCB solutions and the tangible benefits they achieved, such as:

| Company | Industry | CAD2CAM4PCB Benefits |

|---|---|---|

| ABC Electronics | Consumer Electronics | 25% reduction in design cycle time, 15% cost savings in manufacturing |

| XYZ Automotive | Automotive | 30% improvement in design accuracy, 20% reduction in prototyping costs |

| 123 Medical Devices | Medical Devices | 40% faster time-to-market, 10% increase in product reliability |

These success stories demonstrated the real-world impact of CAD2CAM4PCB and inspired attendees to explore the technology further in their own organizations.

The Future of CAD2CAM4PCB

As the PCB industry continues to evolve, the future of CAD2CAM4PCB looks promising. Experts at the seminar discussed the potential advancements and trends that are likely to shape the industry in the coming years, such as:

- Increased adoption of 3D printing for rapid prototyping and small-batch production

- Integration of virtual reality (VR) and augmented reality (AR) in PCB design and visualization

- Expansion of cloud-based CAD2CAM4PCB solutions for enhanced collaboration and accessibility

- Development of more advanced AI and ML algorithms for design optimization and process automation

- Greater emphasis on sustainability and circular economy principles in PCB manufacturing

Frequently Asked Questions (FAQ)

1. What is CAD2CAM4PCB?

CAD2CAM4PCB refers to the integration of computer-aided design (CAD) and Computer-Aided Manufacturing (CAM) technologies specifically for the design and production of printed circuit boards (PCBs). This integration allows for a seamless transition from the design phase to the manufacturing phase, resulting in faster, more efficient, and cost-effective PCB production.

2. What are the benefits of implementing CAD2CAM4PCB in my organization?

Implementing CAD2CAM4PCB in your organization can lead to several benefits, including reduced time-to-market, improved design accuracy, enhanced manufacturability, cost savings through optimized processes, and increased collaboration between design and manufacturing teams.

3. How can I learn more about the latest advancements in CAD2CAM4PCB?

To learn more about the latest advancements in CAD2CAM4PCB, you can attend industry seminars and conferences, such as the CAD2CAM4PCB seminar, read technical publications and blogs, and engage with experts and peers in online forums and communities.

4. What are some of the challenges in adopting CAD2CAM4PCB?

Some of the challenges in adopting CAD2CAM4PCB include the initial investment in software and hardware infrastructure, the need for employee training and upskilling, and the potential disruption to existing workflows and processes. However, the long-term benefits of CAD2CAM4PCB often outweigh these challenges.

5. How can I ensure the successful implementation of CAD2CAM4PCB in my organization?

To ensure the successful implementation of CAD2CAM4PCB in your organization, you should develop a clear strategy and roadmap, involve all relevant stakeholders, allocate sufficient resources for training and support, and continuously monitor and measure the performance and impact of the implementation. Partnering with experienced CAD2CAM4PCB solution providers can also help ensure a smooth and successful transition.

Conclusion

The CAD2CAM4PCB seminar was a resounding success, providing attendees with valuable insights, knowledge, and inspiration to leverage the power of CAD2CAM integration in their PCB design and manufacturing processes. As the industry continues to evolve, staying informed about the latest advancements and best practices in CAD2CAM4PCB will be crucial for organizations looking to remain competitive and deliver high-quality PCB products to their customers.

Leave a Reply