What are PCB Slot Tolerances?

PCB slot tolerances refer to the acceptable range of variation in the size and shape of slots or cutouts on a printed circuit board (PCB). These slots are essential for various purposes, such as mounting components, providing clearance for connectors, or allowing access to underlying layers. Maintaining proper slot tolerances is crucial for ensuring the functionality, reliability, and compatibility of the PCB within its intended application.

Importance of PCB Slot Tolerances

Adhering to specified slot tolerances is important for several reasons:

-

Proper component fitment: Slots that are too small may not allow components to be inserted or may cause damage during assembly. Conversely, oversized slots can result in loose or misaligned components, leading to poor electrical connections and reduced reliability.

-

Mechanical stability: Accurately sized slots contribute to the overall mechanical stability of the PCB. Improper slot dimensions can cause stress points, weaken the board structure, and increase the risk of physical damage during handling or operation.

-

Compatibility with mating parts: PCBs often interface with other components, such as connectors or enclosures. Slot tolerances must be maintained to ensure proper alignment and fitment with these mating parts, preventing issues like poor connections or mechanical interference.

-

Manufacturing consistency: Adhering to slot tolerances helps maintain consistency across multiple production runs. This ensures that PCBs from different batches are interchangeable and meet the same performance standards.

Factors Affecting PCB Slot Tolerances

Several factors can influence the achievable slot tolerances on a PCB:

Material Properties

The choice of PCB substrate material plays a significant role in determining slot tolerances. Different materials exhibit varying degrees of dimensional stability, machinability, and sensitivity to environmental factors like temperature and humidity. Common PCB substrate materials include:

- FR-4: A widely used glass-reinforced epoxy laminate known for its good dimensional stability and mechanical strength.

- Polyimide: A high-performance material with excellent thermal stability and resistance to mechanical stress.

- Aluminum: Used in Metal-Core PCBs for improved heat dissipation, but may require special considerations for slot tolerances due to its unique properties.

Manufacturing Process

The manufacturing process employed to create the slots on the PCB can impact the achievable tolerances. Common methods include:

- Routing: A computer-controlled tool removes material to create the desired slot shape. The accuracy of routing depends on factors like tool size, spindle speed, and material properties.

- Punching: A die is used to punch out the slot shape in a single operation. Punching can provide good accuracy for simple slot geometries but may have limitations for complex shapes.

- Laser cutting: A focused laser beam is used to vaporize the material and create the slot. Laser cutting offers high precision and the ability to create intricate slot patterns but may have limitations on the maximum material thickness.

Slot Geometry

The shape, size, and location of the slots on the PCB can affect the achievable tolerances. Some considerations include:

- Slot dimensions: Larger slots generally have looser tolerances compared to smaller slots. The aspect ratio (length to width) of the slot can also impact the tolerance requirements.

- Slot shape: Simple rectangular or circular slots are easier to maintain tight tolerances compared to complex or irregular shapes.

- Slot location: Slots located near the edges of the PCB or in areas with high component density may have tighter tolerance requirements to ensure proper fitment and avoid interference.

PCB Slot Tolerance Standards and Guidelines

Various industry standards and guidelines provide recommendations for PCB slot tolerances. These standards help ensure consistency and compatibility across different manufacturers and applications. Some widely recognized standards include:

- IPC-6012: Generic Performance Specification for Rigid Printed Boards

- IPC-6013: Qualification and Performance Specification for Flexible/Rigid-Flexible Printed Boards

- IPC-6018: Microwave End Product Board Inspection and Test

These standards specify different tolerance classes based on the intended application and the level of precision required. For example, IPC-6012 defines three tolerance classes:

- Class 1: General electronic products

- Class 2: Dedicated service electronic products

- Class 3: High-reliability electronic products

Each class has specific requirements for slot size tolerances, hole-to-hole spacing, and other dimensional aspects of the PCB.

Communicating Slot Tolerances

When designing a PCB, it is crucial to clearly communicate the desired slot tolerances to the manufacturing team. This ensures that the PCB is fabricated according to the intended specifications and reduces the risk of costly rework or delays. Some best practices for communicating slot tolerances include:

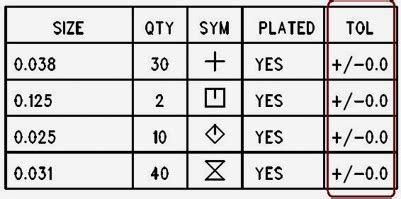

- Provide clear and unambiguous dimensions on the PCB design files, including the nominal slot size and the acceptable tolerance range.

- Use standardized notation and symbols to indicate tolerances, such as ±0.1mm or ±0.005″.

- Specify any special requirements or considerations for slot tolerances, such as tighter tolerances for critical components or areas of the PCB.

- Engage in open communication with the PCB manufacturer to discuss any concerns or limitations related to slot tolerances and to ensure a common understanding of the requirements.

Measuring and Verifying Slot Tolerances

To ensure that the manufactured PCB meets the specified slot tolerances, accurate measurement and verification methods are necessary. Some common techniques include:

- Visual inspection: A simple visual check can identify gross deviations from the intended slot size or shape. However, visual inspection alone may not be sufficient for detecting subtle variations within the tolerance range.

- Caliper measurements: Digital or vernier calipers can provide precise measurements of slot dimensions. Multiple measurements should be taken at different points along the slot to account for any variations.

- Optical comparators: These instruments project a magnified image of the slot onto a screen, allowing for accurate comparison against a reference drawing or template.

- Coordinate measuring machines (CMMs): CMMs use a probe to map the surface of the PCB and provide highly accurate measurements of slot dimensions and positions. CMMs are particularly useful for complex slot geometries or high-precision applications.

Regular measurement and verification of slot tolerances help identify any manufacturing issues early in the process, allowing for timely corrective actions and reducing the risk of non-conforming products.

Designing for Slot Tolerance Optimization

When designing a PCB, there are several strategies that can help optimize slot tolerances and improve manufacturability:

-

Use standardized slot sizes: Whenever possible, use slot sizes that are commonly available and well-suited for the chosen manufacturing process. Standardized sizes reduce the need for custom tooling and can lead to better tolerance control.

-

Provide adequate clearances: Ensure that there is sufficient clearance around slots to accommodate any variations in size or position. This helps prevent interference with nearby components or features on the PCB.

-

Avoid tight tolerances near board edges: Slots located close to the edges of the PCB may be more susceptible to variations due to material handling or manufacturing processes. Providing additional clearance or using looser tolerances in these areas can help mitigate potential issues.

-

Consider the aspect ratio: Long, narrow slots with a high aspect ratio (length to width) can be more challenging to manufacture accurately. Where possible, design slots with a more balanced aspect ratio to improve tolerance control.

-

Use appropriate manufacturing processes: Select manufacturing processes that are well-suited for the desired slot tolerances. For example, laser cutting may be preferred over routing for achieving tight tolerances on small or intricate slot patterns.

-

Collaborate with the manufacturer: Engage in early collaboration with the PCB manufacturer to discuss slot tolerance requirements and any potential design optimizations. Their expertise can provide valuable insights into achievable tolerances and best practices for the specific manufacturing processes and materials being used.

By considering these design strategies and working closely with the manufacturing team, designers can help ensure that the PCB slots are fabricated within the required tolerance ranges, minimizing the risk of issues during assembly and operation.

Table: Common PCB Slot Tolerance Ranges

| Slot Size (mm) | Tolerance (±mm) |

|---|---|

| 0.5 – 1.0 | 0.05 |

| 1.0 – 2.0 | 0.10 |

| 2.0 – 5.0 | 0.15 |

| 5.0 – 10.0 | 0.20 |

| 10.0 – 20.0 | 0.25 |

| 20.0 – 50.0 | 0.30 |

Note: These are general guidelines and actual tolerances may vary based on the specific manufacturing process, material, and other factors. Always consult with the PCB manufacturer for their specific capabilities and recommendations.

Frequently Asked Questions (FAQ)

-

What is the importance of maintaining PCB slot tolerances?

Maintaining PCB slot tolerances is crucial for ensuring proper component fitment, mechanical stability, compatibility with mating parts, and manufacturing consistency. Deviations from the specified tolerances can lead to issues like poor electrical connections, physical damage, or interference with other components. -

What factors can affect the achievable slot tolerances on a PCB?

Several factors can influence the achievable slot tolerances, including the choice of PCB substrate material, the manufacturing process used (e.g., routing, punching, or laser cutting), and the slot geometry (size, shape, and location on the board). -

Are there industry standards that provide guidance on PCB slot tolerances?

Yes, various industry standards, such as IPC-6012, IPC-6013, and IPC-6018, provide recommendations for PCB slot tolerances based on different tolerance classes and intended applications. These standards help ensure consistency and compatibility across different manufacturers and products. -

How can I effectively communicate slot tolerance requirements to the PCB manufacturer?

To communicate slot tolerance requirements effectively, provide clear and unambiguous dimensions on the PCB design files, use standardized notation and symbols, specify any special requirements or considerations, and engage in open communication with the manufacturer to discuss any concerns or limitations. -

What are some design strategies for optimizing slot tolerances on a PCB?

Some strategies for optimizing slot tolerances include using standardized slot sizes, providing adequate clearances, avoiding tight tolerances near board edges, considering the aspect ratio of slots, selecting appropriate manufacturing processes, and collaborating with the manufacturer to discuss design optimizations and best practices.

By understanding the importance of PCB slot tolerances, the factors that affect them, and the strategies for optimizing their design and manufacture, designers and engineers can ensure the reliability, functionality, and compatibility of their PCBs in various applications.

Leave a Reply