Introduction to PCB Manufacturing

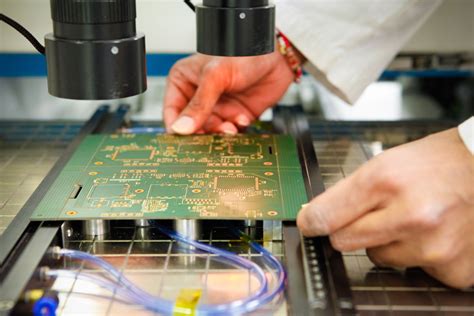

Printed Circuit Boards (PCBs) are the backbone of modern electronics, forming the foundation for countless devices that we rely on in our daily lives. From smartphones and laptops to medical equipment and aerospace systems, PCBs play a crucial role in enabling the functionality and performance of these devices. As the demand for electronics continues to grow, so does the need for efficient and reliable PCB manufacturing processes.

In this article, we will explore the world of PCB manufacturing, focusing on the differences between PCB manufacturers in China and the United States. We will delve into the advantages and disadvantages of each region, the factors that influence the choice of a manufacturing location, and the impact of these decisions on the global electronics industry.

What is PCB Manufacturing?

PCB manufacturing is the process of creating printed circuit boards, which are used to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate. The manufacturing process involves several steps, including:

-

Design: The PCB design is created using specialized software, taking into account the required functionality, component placement, and routing of electrical connections.

-

Fabrication: The designed PCB is fabricated using a combination of chemical etching, drilling, and plating processes to create the conductive pathways and mounting holes for components.

-

Assembly: Electronic components are placed and soldered onto the fabricated PCB, either through manual assembly or automated pick-and-place machines.

-

Testing and Inspection: The assembled PCB undergoes various tests and inspections to ensure proper functionality, quality, and adherence to industry standards.

Importance of PCB Manufacturing Location

The choice of a PCB manufacturing location is a critical decision for electronics companies, as it can significantly impact factors such as cost, quality, lead times, and supply chain management. In recent years, China has emerged as a major player in the global PCB manufacturing industry, offering competitive pricing and large-scale production capabilities. However, the United States has a long-standing history of PCB manufacturing and is known for its high-quality standards and technological expertise.

PCB Manufacturing in China

China has become a global hub for PCB manufacturing, thanks to its vast manufacturing infrastructure, skilled workforce, and favorable government policies. The country’s PCB industry has experienced rapid growth over the past few decades, attracting electronics companies from around the world seeking cost-effective and efficient manufacturing solutions.

Advantages of PCB Manufacturing in China

-

Lower Production Costs: One of the primary advantages of manufacturing PCBs in China is the significantly lower production costs compared to other regions, such as the United States. This is due to factors such as lower labor costs, reduced overhead expenses, and economies of scale achieved through large-scale production.

-

Extensive Supply Chain: China has a well-established and extensive supply chain for PCB manufacturing, with numerous suppliers and vendors providing raw materials, components, and specialized services. This enables manufacturers to source materials and components easily and at competitive prices.

-

Large-Scale Production Capabilities: Chinese PCB manufacturers often have large-scale production facilities equipped with advanced machinery and automated processes, allowing them to handle high-volume orders efficiently. This is particularly advantageous for companies with mass-market products or those requiring large quantities of PCBs.

-

Skilled Workforce: China has a large pool of skilled workers in the PCB manufacturing industry, with many having years of experience and expertise in various aspects of the production process. This skilled workforce contributes to the overall efficiency and quality of PCB manufacturing in China.

Disadvantages of PCB Manufacturing in China

-

Quality Concerns: While many Chinese PCB manufacturers adhere to strict quality standards, there have been instances of inconsistent quality or counterfeit components in the past. This has led some companies to be cautious when sourcing PCBs from China, emphasizing the importance of thorough supplier vetting and quality control measures.

-

Intellectual Property Risks: Intellectual property (IP) protection is a concern for companies manufacturing PCBs in China. There have been cases of IP infringement, reverse engineering, and counterfeiting, which can pose significant risks to businesses. Companies must take necessary precautions to safeguard their IP, such as non-disclosure agreements and careful selection of trusted manufacturing partners.

-

Language and Cultural Barriers: Language and cultural differences can sometimes pose challenges when working with Chinese PCB manufacturers. Miscommunications or misunderstandings can lead to delays, errors, or quality issues. It is essential for companies to establish clear communication channels and work with manufacturers who have experience in dealing with international clients.

-

Longer Lead Times: While China offers cost advantages, the geographical distance and logistics involved can result in longer lead times compared to domestic manufacturing. This can be a consideration for companies with time-sensitive projects or those requiring quick turnaround times.

PCB Manufacturing in the United States

The United States has a long history of PCB manufacturing, with a strong focus on high-quality standards, technological innovation, and stringent regulations. Although the US PCB industry has faced challenges in recent years due to increased global competition, it remains a significant player in the market, particularly for specialized and high-reliability applications.

Advantages of PCB Manufacturing in the United States

-

High Quality Standards: US PCB manufacturers are known for their commitment to high quality standards, adhering to strict industry regulations and certifications such as IPC (Association Connecting Electronics Industries) standards. This emphasis on quality ensures reliable and consistent PCB performance, which is crucial for critical applications in industries such as aerospace, defense, and medical devices.

-

Technological Expertise: The United States is home to many experienced PCB design and manufacturing professionals, with a strong focus on research and development. US manufacturers often specialize in advanced PCB technologies, such as high-density interconnect (HDI), flexible circuits, and RF/microwave PCBs, catering to the needs of cutting-edge electronics applications.

-

Intellectual Property Protection: The United States has robust intellectual property laws and enforcement mechanisms, providing a more secure environment for companies to protect their designs and innovations. This is particularly important for businesses with proprietary technologies or sensitive applications.

-

Proximity and Collaboration: For US-based electronics companies, manufacturing PCBs domestically offers the advantage of proximity and easier collaboration with the manufacturing team. This can facilitate faster problem-solving, design iterations, and shorter lead times, especially for prototyping and low-volume production runs.

Disadvantages of PCB Manufacturing in the United States

-

Higher Costs: PCB Manufacturing Costs in the United States are generally higher compared to countries like China, due to factors such as higher labor costs, stricter regulations, and more expensive raw materials. This can be a significant consideration for companies looking to minimize production costs and remain competitive in the market.

-

Limited Scale: While US PCB manufacturers excel in quality and specialized applications, they may have limitations in terms of production scale compared to their Chinese counterparts. This can be a challenge for companies requiring very high-volume production runs or seeking to achieve significant economies of scale.

-

Aging Workforce: The US PCB manufacturing industry faces a challenge with an aging workforce and a shortage of skilled labor. As experienced professionals retire, there is a need to attract and train a new generation of workers to ensure the long-term sustainability and competitiveness of the industry.

Factors to Consider When Choosing a PCB Manufacturing Location

When deciding between PCB manufacturing in China or the United States, electronics companies must carefully consider various factors that align with their specific needs and priorities. Some key factors to consider include:

-

Cost: Companies must evaluate the total cost of manufacturing, including production costs, shipping, tariffs, and any additional expenses associated with the chosen location. While China generally offers lower production costs, other factors such as tariffs and logistics costs should also be taken into account.

-

Quality and Reliability: The required level of quality and reliability for the PCBs should be a primary consideration. US manufacturers are known for their high-quality standards, which may be essential for critical applications or industries with stringent regulations. However, many Chinese manufacturers also adhere to international quality standards and can provide reliable PCBs when properly vetted.

-

Lead Times: The desired lead times for PCB production and delivery should be factored into the decision. While domestic manufacturing in the US can offer shorter lead times, especially for prototyping and low-volume runs, China’s large-scale production capabilities may be more suitable for high-volume orders.

-

Intellectual Property Protection: Companies with sensitive designs or proprietary technologies should prioritize intellectual property protection when choosing a manufacturing location. The United States offers more robust IP protection compared to China, which may be a critical factor for some businesses.

-

Supply Chain and Logistics: The ease of managing the supply chain and logistics should be considered. Manufacturing in China may require more complex supply chain management and longer shipping times, while domestic production in the US can simplify logistics and provide more control over the supply chain.

-

Technical Expertise: The level of technical expertise and specialized capabilities offered by the manufacturer should align with the company’s requirements. US manufacturers are known for their expertise in advanced PCB technologies, while Chinese manufacturers may have strengths in large-scale production and cost optimization.

-

Long-Term Partnerships: Building long-term partnerships with reliable PCB manufacturers is crucial for ensuring consistent quality, timely delivery, and effective collaboration. Companies should assess the potential for establishing strong partnerships based on factors such as communication, transparency, and track record of the manufacturer.

The Future of PCB Manufacturing

As the electronics industry continues to evolve, the future of PCB manufacturing will be shaped by several key trends and developments:

-

Miniaturization and High-Density Interconnect (HDI): The demand for smaller, more compact electronic devices is driving the need for miniaturized PCBs with high-density interconnects. Manufacturers in both China and the United States are investing in advanced technologies to meet these requirements, such as HDI, embedded components, and 3D packaging.

-

Automation and Industry 4.0: The adoption of automation and Industry 4.0 technologies, such as robotics, artificial intelligence, and the Internet of Things (IoT), is transforming PCB manufacturing processes. These technologies enable greater efficiency, precision, and quality control, while reducing labor costs and human error. Both Chinese and US manufacturers are embracing these advancements to remain competitive in the global market.

-

Sustainable and Eco-Friendly Practices: There is a growing emphasis on sustainable and eco-friendly practices in PCB manufacturing, driven by environmental regulations and customer demands. Manufacturers are exploring ways to reduce waste, minimize the use of hazardous materials, and adopt renewable energy sources. This trend is likely to continue, with companies seeking PCB manufacturers that prioritize sustainability and environmental responsibility.

-

Reshoring and Diversification: The COVID-19 pandemic has highlighted the risks associated with relying heavily on a single manufacturing location, particularly in terms of supply chain disruptions. As a result, some companies are considering reshoring or diversifying their PCB manufacturing to mitigate risks and ensure greater resilience. This may lead to a more balanced distribution of PCB manufacturing between China, the United States, and other regions.

-

Collaboration and Co-Design: Closer collaboration between electronics companies and PCB manufacturers is becoming increasingly important, particularly for complex and specialized applications. Co-design approaches, where the manufacturer is involved early in the design process, can help optimize PCB design for manufacturability, reduce costs, and improve overall product performance. This trend emphasizes the importance of choosing a manufacturing partner with strong technical expertise and a willingness to collaborate closely.

Frequently Asked Questions (FAQ)

- What are the main differences between PCB manufacturing in China and the United States?

-

The main differences lie in cost, quality, scale, and expertise. China offers lower production costs and large-scale manufacturing capabilities, while the United States is known for high-quality standards, technological expertise, and stronger intellectual property protection.

-

How can I ensure the quality of PCBs manufactured in China?

-

To ensure quality when manufacturing PCBs in China, it is essential to thoroughly vet potential suppliers, establish clear quality requirements, and implement robust quality control measures. Working with reputable manufacturers who have experience serving international clients and adhere to industry standards can help mitigate quality risks.

-

Are there any tariffs or trade restrictions I should be aware of when importing PCBs from China to the United States?

-

Yes, there are tariffs and trade restrictions that can impact the cost and logistics of importing PCBs from China to the United States. It is important to stay informed about the latest trade policies and work with experienced logistics partners to navigate these challenges effectively.

-

What are the advantages of choosing a US-based PCB manufacturer for my high-reliability application?

-

US-based PCB manufacturers offer several advantages for high-reliability applications, including strict adherence to quality standards, technological expertise in advanced PCB technologies, strong intellectual property protection, and closer collaboration opportunities. These factors can be crucial for applications in industries such as aerospace, defense, and medical devices.

-

How can I decide whether to manufacture my PCBs in China or the United States?

- The decision to manufacture PCBs in China or the United States should be based on a careful evaluation of your specific needs and priorities. Consider factors such as cost, quality, lead times, intellectual property protection, supply chain management, and technical expertise. Weigh the advantages and disadvantages of each location against your requirements to determine the best fit for your business.

Conclusion

The choice between PCB manufacturing in China and the United States is a complex decision that depends on a variety of factors unique to each electronics company. While China offers cost advantages and large-scale production capabilities, the United States is known for its high-quality standards, technological expertise, and robust intellectual property protection.

Companies must carefully consider their priorities, such as cost, quality, lead times, and supply chain management, when deciding on a manufacturing location. It is also essential to stay informed about the latest industry trends, such as miniaturization, automation, sustainability, and reshoring, as these developments will shape the future of PCB manufacturing.

Ultimately, the key to successful PCB manufacturing, regardless of location, lies in choosing a reliable and experienced manufacturing partner that aligns with your company’s goals and values. By fostering strong partnerships, maintaining open communication, and staying adaptable to change, electronics companies can navigate the complexities of the global PCB manufacturing landscape and achieve long-term success in their endeavors.

| Factor | China | United States |

|---|---|---|

| Production Costs | Lower labor costs and overhead expenses | Higher labor costs and stricter regulations |

| Quality Standards | Varying quality, requiring thorough supplier vetting | High quality standards and adherence to industry regulations |

| Manufacturing Scale | Large-scale production capabilities and infrastructure | Limitations in very high-volume production runs |

| Technological Expertise | Strengths in cost optimization and large-scale production | Expertise in advanced PCB technologies and specialized applications |

| Intellectual Property | Concerns over IP infringement and counterfeiting | Robust IP laws and enforcement mechanisms |

| Lead Times | Longer lead times due to geographical distance | Shorter lead times, especially for prototyping and low-volume runs |

| Supply Chain Management | Complex supply chain and logistics, requiring careful management | Simplified logistics and greater control over the supply chain |

Table 1: Comparison of key factors between PCB manufacturing in China and the United States.

By carefully weighing these factors and aligning them with their specific needs, electronics companies can make informed decisions about where to manufacture their PCBs. The global PCB manufacturing landscape will continue to evolve, and companies must remain agile and adaptable to stay competitive in this dynamic industry.

Leave a Reply