What is PCB thermal conductivity?

PCB (Printed Circuit Board) thermal conductivity refers to the ability of a PCB material to conduct heat. It is a crucial property that determines how effectively heat can be transferred from the components on the PCB to the surrounding environment. Thermal conductivity is measured in watts per meter-kelvin (W/mK) and varies depending on the materials used in the construction of the PCB.

Factors Affecting PCB Thermal Conductivity

Several factors influence the thermal conductivity of a PCB:

-

Material composition: The choice of materials used in the PCB, such as the substrate, copper layers, and solder mask, play a significant role in determining the overall thermal conductivity.

-

Thickness: The thickness of the PCB and its layers can impact the thermal conductivity. Thicker boards generally have better thermal conductivity compared to thinner ones.

-

Copper coverage: The amount and distribution of copper on the PCB affect its ability to dissipate heat. Higher copper coverage usually results in better thermal conductivity.

-

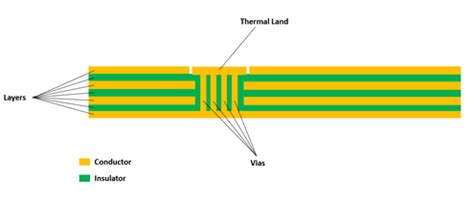

Vias: Thermal vias, which are conductive paths drilled through the PCB, can enhance thermal conductivity by providing additional pathways for heat dissipation.

Importance of PCB Thermal Conductivity

Ensuring Component Reliability

One of the primary reasons why PCB thermal conductivity is crucial is its impact on component reliability. Electronic components generate heat during operation, and if this heat is not effectively dissipated, it can lead to several problems:

-

Overheating: Excessive heat can cause components to operate beyond their specified temperature range, leading to reduced performance, malfunctions, or even permanent damage.

-

Shortened lifespan: Prolonged exposure to high temperatures accelerates the aging process of electronic components, resulting in a shorter lifespan and increased failure rates.

-

Signal integrity issues: Heat can affect the electrical properties of components and the PCB itself, potentially causing signal integrity problems, such as increased noise, crosstalk, or timing errors.

By ensuring adequate thermal conductivity, PCBs can efficiently transfer heat away from the components, maintaining their operating temperature within acceptable limits and enhancing overall reliability.

Improving System Performance

PCB thermal conductivity also plays a vital role in optimizing system performance. When heat is not effectively dissipated, it can lead to performance throttling or even system shutdown to prevent damage. This is particularly relevant in high-performance applications, such as:

-

High-speed digital systems: In systems with high clock speeds and dense component placement, effective heat dissipation is essential to maintain stable operation and prevent performance degradation.

-

Power electronics: Power-hungry components, such as voltage regulators, power amplifiers, and high-current drivers, generate significant amounts of heat. Efficient thermal management through proper PCB design and material selection is crucial to ensure optimal performance and reliability.

-

Compact devices: As electronic devices become smaller and more compact, the challenge of heat dissipation becomes more critical. Good thermal conductivity allows for efficient heat transfer in space-constrained designs, enabling the development of compact and high-performance devices.

Environmental Impact and Sustainability

Effective thermal management through appropriate PCB thermal conductivity also contributes to environmental sustainability. When electronic systems operate at lower temperatures, they consume less power and generate less waste heat. This translates to several benefits:

-

Energy efficiency: Lower power consumption reduces the overall energy footprint of electronic devices, contributing to energy conservation and cost savings.

-

Reduced cooling requirements: Efficient heat dissipation reduces the need for additional cooling solutions, such as heatsinks or fans, which consume extra power and add to the system’s complexity and cost.

-

Extended product lifespan: By maintaining components within their optimal temperature range, PCBs with good thermal conductivity contribute to extending the lifespan of electronic products, reducing electronic waste and promoting sustainability.

Strategies for Improving PCB Thermal Conductivity

To enhance the thermal conductivity of PCBs, several strategies can be employed during the design and manufacturing process:

Material Selection

Choosing materials with higher thermal conductivity can significantly improve the overall heat dissipation capabilities of the PCB. Some commonly used materials with good thermal conductivity include:

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Copper | 385 – 400 |

| Aluminum | 205 – 230 |

| Gold | 314 – 318 |

| Silver | 406 – 429 |

In addition to the conductive layers, the choice of substrate material also affects the thermal conductivity. Some high-performance substrate materials, such as aluminum nitride (AlN) and beryllium oxide (BeO), offer excellent thermal conductivity compared to standard FR-4 substrates.

Optimizing Copper Coverage

Increasing the amount of copper on the PCB can improve its thermal conductivity. This can be achieved through techniques such as:

-

Thicker copper layers: Using thicker copper layers, especially on the outer layers of the PCB, enhances heat spreading and dissipation.

-

Copper pour: Filling unused areas of the PCB with copper, known as copper pour or copper fill, creates additional thermal paths and improves overall conductivity.

-

Thermal vias: Strategically placing thermal vias near heat-generating components helps transfer heat through the PCB Layers and dissipate it more effectively.

Thermal Interface Materials (TIMs)

Thermal interface materials are substances applied between the PCB and heat-generating components to facilitate heat transfer. TIMs fill the microscopic air gaps and improve thermal conductivity. Some commonly used TIMs include:

- Thermal greases

- Thermal pads

- Phase-change materials

- Thermal adhesives

Selecting the appropriate TIM based on the specific application, thermal requirements, and compatibility with the PCB and components is crucial for optimal thermal management.

Thermal Simulation and Analysis

Conducting thermal simulations and analysis during the PCB design phase helps identify potential thermal issues and optimize the layout for better heat dissipation. Thermal simulation software tools allow designers to:

- Predict temperature distributions across the PCB

- Identify hot spots and areas of thermal concern

- Evaluate the effectiveness of thermal management strategies

- Optimize component placement and copper distribution for improved thermal performance

By iterating and refining the PCB design based on thermal simulation results, designers can ensure that the final product meets the required thermal specifications and reliability standards.

Frequently Asked Questions (FAQ)

- What is the typical thermal conductivity range for PCB materials?

-

The thermal conductivity of PCB materials varies widely depending on the specific material composition. Standard FR-4 substrates have a thermal conductivity of around 0.3 to 0.4 W/mK, while high-performance materials like aluminum nitride (AlN) can have thermal conductivities up to 170 W/mK.

-

How does the number of PCB layers affect thermal conductivity?

-

Generally, increasing the number of PCB layers can improve thermal conductivity by providing more paths for heat dissipation. However, the effectiveness depends on factors such as the layer stack-up, material properties, and the presence of thermal vias.

-

Can thermal vias be used in multilayer PCBs?

-

Yes, thermal vias can be incorporated into multilayer PCBs to enhance heat transfer through the layers. They act as conductive paths, allowing heat to flow from inner layers to outer layers or to dedicated heatsinks.

-

What is the impact of solder mask on PCB thermal conductivity?

-

Solder mask, applied on the outer layers of the PCB, has a lower thermal conductivity compared to the copper layers. While it provides essential protection and insulation, it can slightly impede heat dissipation. Careful selection of solder mask materials and optimizing the coverage can help minimize its impact on thermal conductivity.

-

How can thermal conductivity be measured for PCBs?

- Thermal conductivity of PCBs can be measured using specialized equipment and techniques, such as the guarded heat flow meter method or the laser flash method. These methods involve applying a heat source to the PCB and measuring the temperature gradient or the time taken for heat to propagate through the material. Accurate thermal conductivity measurements are essential for validating thermal simulations and ensuring the PCB meets the required thermal specifications.

Conclusion

PCB thermal conductivity is a critical aspect of electronic design, directly impacting the reliability, performance, and sustainability of electronic systems. By understanding the factors that influence thermal conductivity and employing appropriate design strategies, engineers can create PCBs that effectively dissipate heat, maintain optimal operating temperatures, and ensure the long-term reliability of components.

Through careful material selection, optimized copper coverage, the use of thermal interface materials, and thorough thermal simulation and analysis, designers can overcome thermal challenges and develop high-performance, reliable, and environmentally friendly electronic products.

As the demand for compact, high-performance electronics continues to grow, the importance of PCB thermal conductivity will only increase. By staying updated with the latest advancements in materials, design techniques, and simulation tools, engineers can effectively address thermal management challenges and contribute to the development of innovative and sustainable electronic solutions.

Leave a Reply