Understanding the Basics of Power PCB Design

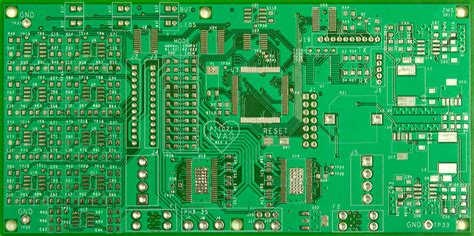

Before diving into the specifics of power PCB design, it’s essential to understand the basics. A power PCB is a printed circuit board that is designed to distribute power to various components within an electronic device. The main goal of a power PCB is to provide a stable and reliable power supply while minimizing noise and electromagnetic interference (EMI).

Key Components in Power PCB Design

There are several key components that are commonly used in power PCB design. These include:

- Power supply: The power supply is the source of power for the PCB. It can be a battery, a wall adapter, or a power supply unit (PSU).

- Voltage regulator: A voltage regulator is used to maintain a constant voltage level, even when the load on the PCB changes.

- Capacitors: Capacitors are used to smooth out voltage fluctuations and reduce noise.

- Inductors: Inductors are used to store energy and filter out high-frequency noise.

- Resistors: Resistors are used to limit current flow and provide voltage division.

PCB Material Selection

Choosing the right PCB material is crucial for power PCB design. The most common materials used for power PCBs are FR-4 and aluminum. FR-4 is a flame-retardant material that is commonly used for low-power applications. Aluminum, on the other hand, is used for high-power applications due to its excellent thermal conductivity.

| Material | Thermal Conductivity (W/mK) | Dielectric Constant | Loss Tangent |

|---|---|---|---|

| FR-4 | 0.3 | 4.5 | 0.02 |

| Aluminum | 205 | – | – |

Designing for Efficiency and Reliability

One of the main goals of power PCB design is to achieve high efficiency and reliability. This means minimizing power losses and ensuring that the PCB can operate safely under various conditions.

Minimizing Power Losses

Power losses can occur due to several factors, such as resistance in the PCB traces, switching losses in the voltage regulators, and leakage current in the capacitors. To minimize power losses, designers should:

- Use wide and short PCB traces to reduce resistance.

- Choose voltage regulators with high efficiency and low quiescent current.

- Use low-ESR capacitors to reduce losses due to equivalent series resistance (ESR).

Ensuring Safe Operation

Power PCBs must be designed to operate safely under various conditions, such as over-voltage, over-current, and short-circuit conditions. To ensure safe operation, designers should:

- Use fuses or circuit breakers to protect against over-current conditions.

- Use transient voltage suppressors (TVS) to protect against voltage spikes.

- Use thermal management techniques, such as heatsinks and thermal vias, to prevent overheating.

Layout Considerations for Power PCB Design

The layout of a power PCB is critical for achieving optimal performance and reliability. Here are some key layout considerations that beginners should keep in mind:

Grounding and Shielding

Proper grounding and shielding are essential for minimizing noise and EMI in power PCBs. Designers should:

- Use a solid ground plane to provide a low-impedance return path for current.

- Use ground stitching vias to connect the ground plane on different layers.

- Use shielding techniques, such as copper pours and shielding cans, to reduce EMI.

Component Placement

Component placement is another important consideration in power PCB layout. Components should be placed in a way that minimizes the length of PCB traces and reduces the risk of interference. Designers should:

- Place power components, such as voltage regulators and capacitors, close to the power supply.

- Place sensitive components, such as analog circuits and high-speed digital circuits, away from noisy components.

- Use component orientation to minimize the length of PCB traces.

Thermal Management

Thermal management is critical for ensuring the reliability and longevity of power PCBs. Designers should:

- Use thermal vias to transfer heat from components to the PCB substrate.

- Use heatsinks or other cooling methods to dissipate heat from high-power components.

- Use thermal simulations to identify hot spots and optimize the PCB layout for thermal performance.

Simulation and Testing

Simulation and testing are essential steps in the power PCB design process. They help designers to identify potential issues and optimize the design before manufacturing.

Simulation Tools

There are several simulation tools available for power PCB design, such as:

- SPICE: SPICE (Simulation Program with Integrated Circuit Emphasis) is a widely used tool for simulating electronic circuits.

- ANSYS: ANSYS is a multiphysics simulation tool that can be used for thermal and electromagnetic simulations.

- COMSOL: COMSOL is another multiphysics simulation tool that can be used for a wide range of simulations, including thermal and electromagnetic simulations.

Testing Methods

Once the power PCB is manufactured, it’s essential to test it to ensure that it meets the design specifications. Some common testing methods include:

- Functional testing: Functional testing involves testing the PCB under normal operating conditions to ensure that it functions as intended.

- Environmental testing: Environmental testing involves exposing the PCB to various environmental conditions, such as temperature and humidity, to ensure that it can operate reliably under these conditions.

- EMI testing: EMI testing involves measuring the electromagnetic emissions from the PCB to ensure that they are within acceptable limits.

Best Practices for Power PCB Design

Here are some best practices that beginners should follow when designing power PCBs:

- Use a modular design approach to simplify the design process and improve scalability.

- Use a consistent naming convention for components and nets to avoid confusion.

- Use a version control system to track changes and collaborate with other designers.

- Document the design thoroughly, including schematics, layouts, and bill of materials (BOM).

- Follow industry standards and guidelines, such as IPC standards, to ensure compatibility and reliability.

Frequently Asked Questions (FAQ)

- What is the difference between a power PCB and a regular PCB?

-

A power PCB is specifically designed to distribute power to various components within an electronic device, while a regular PCB is designed for signal routing and processing.

-

What are the most common materials used for power PCBs?

-

The most common materials used for power PCBs are FR-4 and aluminum. FR-4 is used for low-power applications, while aluminum is used for high-power applications due to its excellent thermal conductivity.

-

What are some common causes of power losses in power PCBs?

-

Power losses in power PCBs can occur due to several factors, such as resistance in the PCB traces, switching losses in the voltage regulators, and leakage current in the capacitors.

-

What are some common thermal management techniques used in power PCB design?

-

Common thermal management techniques used in power PCB design include using thermal vias to transfer heat from components to the PCB substrate, using heatsinks or other cooling methods to dissipate heat from high-power components, and using thermal simulations to identify hot spots and optimize the PCB layout for thermal performance.

-

What are some best practices for power PCB design?

- Some best practices for power PCB design include using a modular design approach, using a consistent naming convention for components and nets, using a version control system to track changes and collaborate with other designers, documenting the design thoroughly, and following industry standards and guidelines.

In conclusion, designing a power PCB can be a complex and challenging task for beginners. However, by understanding the basics of power PCB design, designing for efficiency and reliability, considering layout considerations, using simulation and testing tools, and following best practices, beginners can create high-quality power PCBs that meet the demands of modern electronic devices.

Leave a Reply