Introduction to PCB assembly

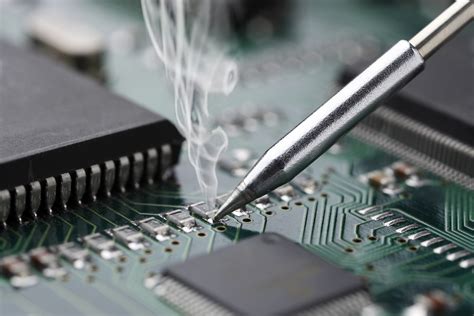

Printed Circuit Board (PCB) assembly is the process of soldering electronic components onto a PCB to create a functional electronic device. PCB assembly service providers offer a range of services to help businesses and individuals bring their electronic designs to life. In this article, we will explore the world of PCB assembly, the services offered by PCB assembly providers, and the Standard Operating Procedure (SOP) package that ensures high-quality and consistent results.

What is PCB Assembly?

PCB assembly involves the following steps:

- Solder Paste Application

- Component Placement

- Reflow Soldering

- Inspection and Testing

The process begins with the application of solder paste onto the PCB’s pads using a stencil. Next, surface mount components are placed onto the solder paste using pick-and-place machines. The PCB then goes through a reflow oven, where the solder paste melts and forms a permanent connection between the components and the PCB. Finally, the assembled PCB undergoes inspection and testing to ensure proper functionality and quality.

PCB Assembly Service Providers

Types of PCB Assembly Services

PCB assembly service providers offer a range of services to cater to different needs and requirements. Some of the common types of PCB assembly services include:

-

Prototype Assembly: This service is suitable for businesses and individuals who need a small number of PCBs for testing and evaluation purposes.

-

Low-Volume Production: Low-volume production services cater to businesses that require a few hundred to a few thousand PCBs for their products.

-

High-Volume Production: High-volume production services are designed for businesses that require large quantities of PCBs, typically in the range of tens of thousands to millions.

-

Turnkey Solutions: Turnkey PCB assembly services provide end-to-end solutions, from PCB design and fabrication to component sourcing and final assembly.

Choosing the Right PCB Assembly Service Provider

When choosing a PCB assembly service provider, consider the following factors:

-

Experience and Expertise: Look for a provider with a proven track record and expertise in the specific type of PCB assembly you require.

-

Quality Standards: Ensure that the provider adheres to industry-standard quality standards, such as IPC-A-610, to guarantee the reliability and performance of the assembled PCBs.

-

Technology and Equipment: Choose a provider that invests in state-of-the-art technology and equipment to ensure precise and efficient PCB assembly.

-

Customer Support: Select a provider that offers excellent customer support and communication throughout the PCB assembly process.

| Factor | Description |

|---|---|

| Experience and Expertise | Provider should have a proven track record and expertise in the required PCB assembly type |

| Quality Standards | Provider must adhere to industry-standard quality standards (e.g., IPC-A-610) |

| Technology and Equipment | Provider should invest in state-of-the-art technology and equipment for precise and efficient assembly |

| Customer Support | Provider must offer excellent customer support and communication throughout the assembly process |

Standard Operating Procedure (SOP) Package

A Standard Operating Procedure (SOP) package is a set of documents that outline the processes, guidelines, and best practices for PCB assembly. An SOP package ensures consistency, quality, and efficiency in the PCB assembly process.

Components of an SOP Package

A typical SOP package for PCB assembly includes the following components:

-

Process Flow Chart: A visual representation of the PCB assembly process, including all the steps from start to finish.

-

Work Instructions: Detailed instructions for each step of the PCB assembly process, including equipment setup, material handling, and quality control measures.

-

Inspection and Testing Procedures: Guidelines for inspecting and testing the assembled PCBs to ensure they meet the required quality standards.

-

Training Materials: Documents and resources used to train operators and technicians on the PCB assembly process and best practices.

-

Quality Control Checklists: Checklists used to verify that each step of the PCB assembly process has been completed correctly and that the assembled PCBs meet the required quality standards.

Benefits of an SOP Package

Implementing an SOP package offers several benefits for PCB assembly service providers and their clients:

-

Consistency: An SOP package ensures that the PCB assembly process is consistent across different projects and teams, reducing variability and errors.

-

Quality: By following the guidelines and best practices outlined in the SOP package, PCB assembly service providers can deliver high-quality assembled PCBs that meet or exceed industry standards.

-

Efficiency: An SOP package streamlines the PCB assembly process, reducing waste, minimizing downtime, and improving overall efficiency.

-

Traceability: The documentation provided in an SOP package allows for easy traceability of the PCB assembly process, which is essential for troubleshooting and continuous improvement.

Frequently Asked Questions (FAQ)

1. What is the difference between surface mount and Through-hole PCB assembly?

Surface mount PCB assembly involves soldering components directly onto the surface of the PCB, while through-hole assembly requires components to be inserted into holes drilled in the PCB and soldered on the opposite side. Surface mount assembly is generally faster and more suitable for high-density designs, while through-hole assembly is more robust and easier to repair.

2. How long does the PCB assembly process typically take?

The duration of the PCB assembly process depends on various factors, such as the complexity of the design, the number of components, and the quantity of PCBs required. Prototype assembly can take a few days to a week, while high-volume production may take several weeks or even months.

3. What is the minimum order quantity for PCB assembly services?

The minimum order quantity (MOQ) for PCB assembly services varies depending on the service provider and the type of service required. Some providers offer low MOQs for prototype assembly, while others may require a higher MOQ for low-volume or high-volume production.

4. How can I ensure the quality of the assembled PCBs?

To ensure the quality of the assembled PCBs, choose a PCB assembly service provider that adheres to industry-standard quality standards, such as IPC-A-610. Additionally, request a detailed quality control report and consider performing your own incoming inspection and testing upon receiving the assembled PCBs.

5. Can PCB assembly service providers source components for my design?

Yes, many PCB assembly service providers offer component sourcing as part of their turnkey solutions. They can help you procure the required components based on your bill of materials (BOM) and ensure that the components are compatible with your design and meet the necessary quality standards.

Conclusion

PCB assembly is a critical process in the production of electronic devices, and choosing the right PCB assembly service provider is essential for ensuring the success of your project. By understanding the different types of PCB assembly services available, the factors to consider when selecting a provider, and the importance of an SOP package, you can make an informed decision and achieve high-quality, consistent results.

When partnering with a PCB assembly service provider, look for a company that offers the expertise, technology, and customer support needed to bring your electronic designs to life. By working closely with your chosen provider and leveraging their knowledge and resources, you can streamline your PCB assembly process, reduce costs, and deliver superior products to your customers.

Leave a Reply