Introduction to PCB Assembly

Printed Circuit Board (PCB) assembly is a crucial process in the electronics manufacturing industry. It involves the placement and soldering of electronic components onto a PCB to create a functional electronic device. There are two primary methods of PCB assembly: surface mount technology (SMT) and through-hole technology (THT). In this article, we will focus on Through-hole PCB assembly and the companies that specialize in this process.

What is Through-Hole PCB Assembly?

Through-hole PCB assembly, also known as thru-hole or leaded assembly, is a method of mounting electronic components onto a PCB by inserting their leads through drilled holes in the board and soldering them to pads on the opposite side. This technique has been used for decades and is still popular for certain applications, despite the growing dominance of SMT.

Advantages of Through-Hole PCB Assembly

- Stronger mechanical connections

- Better suited for high-power and high-voltage applications

- Easier to inspect and repair

- More accessible for hobbyists and low-volume production

Disadvantages of Through-Hole PCB Assembly

- Larger component footprints

- Slower assembly process compared to SMT

- Limited component density

- Higher manufacturing costs for high-volume production

Thru Hole PCB Assembly Process

The through-hole PCB assembly process consists of several steps:

-

PCB Design and Fabrication: The PCB is designed using CAD software, and the design files are sent to a PCB fabrication company to create the bare board.

-

Component Preparation: Through-hole components are prepared by straightening and cutting their leads to the appropriate length.

-

Component Insertion: Components are inserted into the drilled holes on the PCB, either manually or using automated insertion machines.

-

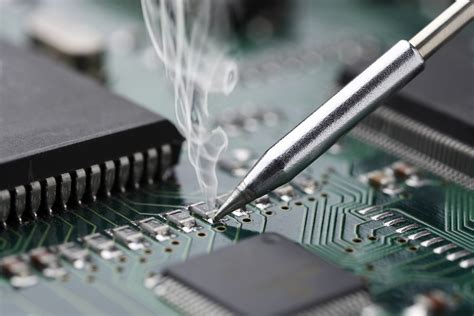

Soldering: The leads of the components are soldered to the pads on the opposite side of the board, creating electrical and mechanical connections. This can be done using wave soldering, selective soldering, or hand soldering techniques.

-

Inspection and Testing: The assembled PCB undergoes visual inspection and electrical testing to ensure proper functionality and adherence to quality standards.

-

Cleaning and Finishing: The PCB is cleaned to remove any residual flux or contaminants and may undergo additional finishing processes, such as conformal coating or potting.

Thru Hole PCB Assembly Equipment

To perform through-hole PCB assembly, companies use various equipment, including:

-

Insertion Machines: Automated machines that insert through-hole components into the PCB at high speeds.

-

Wave Soldering Machines: Used for mass soldering of through-hole components by passing the PCB over a wave of molten solder.

-

Selective Soldering Machines: Allows for precise soldering of specific through-hole components without affecting nearby SMT components.

-

Hand Soldering Tools: Used for manual soldering of through-hole components, especially for prototypes, repairs, or low-volume production.

-

Inspection Systems: Automated optical inspection (AOI) and X-ray inspection systems are used to detect soldering defects and ensure the quality of the assembled PCBs.

Choosing a Thru Hole PCB Assembly Company

When selecting a through-hole PCB assembly company, consider the following factors:

-

Experience and Expertise: Look for a company with a proven track record in through-hole PCB assembly and experience working with projects similar to yours.

-

Quality Standards: Ensure that the company adheres to industry-recognized quality standards, such as IPC-A-610, and has a robust quality management system in place.

-

Production Capabilities: Assess the company’s production capacity, lead times, and ability to handle your specific volume requirements.

-

Technology and Equipment: Verify that the company has the necessary equipment and technology to meet your through-hole PCB assembly needs.

-

Customer Support and Communication: Choose a company that offers excellent customer support, responsive communication, and a willingness to collaborate on your project.

-

Pricing and Value: While cost is an important consideration, also evaluate the overall value provided by the company, including quality, reliability, and additional services.

Top Thru Hole PCB Assembly Companies

Here are some of the leading through-hole PCB assembly companies:

| Company | Location | Website |

|---|---|---|

| Advanced Assembly | Aurora, CO, USA | www.aapcb.com |

| FFD Assembly | San Francisco, CA, USA | www.ffdassembly.com |

| Sierra Circuits | Sunnyvale, CA, USA | www.protoexpress.com |

| Tramonto Circuits | Littleton, CO, USA | www.tramontocircuits.com |

| Turnkey PCB | Milpitas, CA, USA | www.turnkeypcb.com |

| Merlin PCB Group | Cambridgeshire, UK | www.merlinpcbgroup.com |

| MOKO Technology | Shenzhen, China | www.mokotechnology.com |

| PCBWay | Shenzhen, China | www.pcbway.com |

| Seeed Studio | Shenzhen, China | www.seeedstudio.com |

| Bittele Electronics | Toronto, ON, Canada | www.7pcb.com |

These companies offer a range of through-hole PCB assembly services, from prototype to high-volume production, and cater to various industries, including automotive, medical, aerospace, and consumer electronics.

Applications of Thru Hole PCB Assembly

Through-hole PCB assembly is used in various applications, such as:

-

High-Power Electronics: Power supply units, inverters, and motor controllers often use through-hole components due to their ability to handle high currents and voltages.

-

Automotive Electronics: Some automotive electronic systems, such as engine control units and sensors, rely on through-hole PCB assembly for its reliability and vibration resistance.

-

Military and Aerospace: Through-hole PCB assembly is preferred in military and aerospace applications, where reliability and durability under extreme conditions are critical.

-

Medical Devices: Certain medical devices, like patient monitors and diagnostic equipment, use through-hole components for their robustness and ease of maintenance.

-

Prototyping and Low-Volume Production: Through-hole PCB assembly is often used for prototyping and low-volume production runs, as it is more accessible and cost-effective for smaller quantities.

Future of Thru Hole PCB Assembly

While SMT has become the dominant PCB assembly method, through-hole technology continues to play a significant role in the electronics industry. Some trends and developments in through-hole PCB assembly include:

-

Hybrid Assembly: Many PCBs now use a combination of SMT and through-hole components, leveraging the strengths of both technologies.

-

Advanced Insertion Machines: Newer through-hole insertion machines offer higher speeds, improved accuracy, and the ability to handle a wider range of component types and sizes.

-

Selective Soldering Advancements: Selective soldering machines are becoming more sophisticated, with better control over the soldering process and the ability to handle more complex board layouts.

-

Increased Automation: Through-hole PCB assembly is seeing greater levels of automation, with the integration of robotics and machine vision systems to improve efficiency and quality.

-

Focus on Sustainability: Companies are increasingly adopting environmentally friendly through-hole PCB assembly practices, such as using lead-free solder and implementing waste reduction initiatives.

Conclusion

Through-hole PCB assembly remains an essential technology in the electronics manufacturing industry, offering unique advantages for certain applications. When choosing a through-hole PCB assembly company, it is crucial to consider factors such as experience, quality standards, production capabilities, and customer support. By partnering with a reliable and experienced company, you can ensure the success of your through-hole PCB assembly projects.

Frequently Asked Questions (FAQ)

-

What is the difference between through-hole and surface mount PCB assembly?

Through-hole PCB assembly involves inserting component leads through drilled holes in the PCB and soldering them to pads on the opposite side, while surface mount assembly places components directly onto pads on the PCB surface and solders them in place. -

When should I choose through-hole PCB assembly over surface mount?

Through-hole PCB assembly is preferred when stronger mechanical connections, high power handling, or easier repairability are required. It is also often used for prototyping and low-volume production. -

Can through-hole and surface mount components be used on the same PCB?

Yes, many PCBs use a combination of through-hole and surface mount components in a hybrid assembly approach, leveraging the strengths of both technologies. -

What are the most common through-hole soldering methods?

The most common through-hole soldering methods include wave soldering, selective soldering, and hand soldering. Wave soldering is used for mass soldering, selective soldering for specific components, and hand soldering for prototypes or repairs. -

How do I ensure the quality of my through-hole PCB assembly?

To ensure the quality of your through-hole PCB assembly, choose a company that adheres to industry-recognized quality standards, such as IPC-A-610, and has a robust quality management system in place. Additionally, consider the company’s experience, production capabilities, and customer support when making your selection.

Leave a Reply