Introduction to Soldermask Thickness

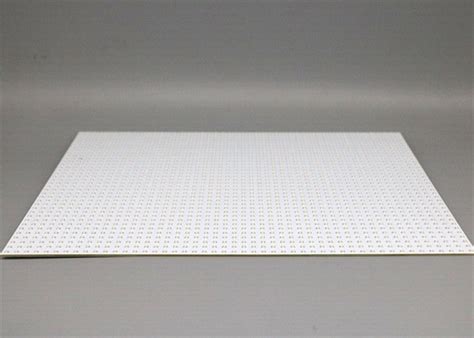

Soldermask, also known as solder resist or solder mask, is a thin layer of polymer applied to the copper traces of a printed circuit board (PCB) to protect them from oxidation, prevent solder bridges, and provide electrical insulation. The thickness of the soldermask plays a crucial role in the performance, reliability, and manufacturability of PCBs. In this article, we will explore the impact of soldermask thickness on various aspects of PCB design and production.

What is Soldermask?

Soldermask is a protective coating that is applied to the copper traces of a PCB during the manufacturing process. It serves several important functions:

-

Oxidation prevention: Soldermask prevents the exposed copper traces from oxidizing, which can lead to reduced conductivity and poor solderability.

-

Solder bridge prevention: By covering the copper traces, soldermask prevents accidental solder bridges between adjacent pads or traces during the soldering process.

-

Electrical insulation: Soldermask provides electrical insulation between conductive elements on the PCB, reducing the risk of short circuits and improving signal integrity.

-

Aesthetic enhancement: Soldermask is available in various colors, allowing for improved visual contrast and aesthetics of the PCB.

Soldermask Application Methods

There are two primary methods for applying soldermask to a PCB:

-

Liquid photoimageable soldermask (LPISM): This method involves applying a liquid soldermask coating to the PCB, which is then exposed to UV light through a photomask. The exposed areas are cured, while the unexposed areas are removed during development. LPISM is the most common method for applying soldermask in the PCB industry.

-

Dry film soldermask (DFSM): In this method, a dry film soldermask is laminated onto the PCB surface using heat and pressure. The soldermask is then exposed to UV light through a photomask, and the unexposed areas are removed during development. DFSM is less common than LPISM but offers some advantages, such as better thickness control and improved edge definition.

Impact of Soldermask Thickness on PCB Performance

The thickness of the soldermask layer can significantly impact various aspects of PCB performance, including:

Impedance Control

Soldermask thickness plays a role in controlling the impedance of PCB traces. The dielectric constant of the soldermask material and its thickness contribute to the overall impedance of the traces. Thicker soldermask layers can increase the impedance of the traces, while thinner layers can decrease it. Maintaining consistent soldermask thickness is essential for achieving the desired impedance values and ensuring proper signal integrity.

Signal Integrity

Soldermask thickness can also affect signal integrity in high-speed PCB designs. Thicker soldermask layers can increase the capacitance between adjacent traces, leading to increased crosstalk and signal distortion. On the other hand, thinner soldermask layers may not provide sufficient insulation, increasing the risk of short circuits and signal degradation. Designers must carefully consider the soldermask thickness in relation to the trace geometry and spacing to optimize signal integrity.

Thermal Management

The soldermask layer acts as a thermal insulator, affecting the heat dissipation capabilities of the PCB. Thicker soldermask layers can impede heat transfer from the components to the PCB substrate, leading to higher operating temperatures and reduced reliability. Conversely, thinner soldermask layers may not provide adequate protection against environmental factors, such as moisture and contaminants, which can also impact the longevity of the PCB. Designers must strike a balance between thermal management and protection when selecting the appropriate soldermask thickness.

Soldermask Thickness and Manufacturing Considerations

In addition to its impact on PCB performance, soldermask thickness also influences various manufacturing aspects, such as:

Solder Paste Printing

The thickness of the soldermask layer can affect the solder paste printing process. If the soldermask is too thick, it can cause issues with solder paste release from the stencil, resulting in insufficient or inconsistent solder paste deposits. This can lead to poor solderability and reduced reliability of the solder joints. On the other hand, if the soldermask is too thin, it may not provide adequate support for the stencil, leading to solder paste bleeding and bridging between pads.

Component Assembly

Soldermask thickness can also impact the component assembly process. If the soldermask is too thick, it can create a step between the pad and the surrounding area, making it difficult to place small components accurately. This can result in component misalignment, poor solder joint formation, and reduced reliability. Conversely, if the soldermask is too thin, it may not provide sufficient insulation between adjacent pads, increasing the risk of solder bridges and short circuits during the reflow process.

Via Plugging

In some PCB designs, it is necessary to plug the vias with soldermask to prevent solder from wicking into the via during the soldering process. The thickness of the soldermask layer can affect the effectiveness of via plugging. If the soldermask is too thin, it may not completely fill the via, allowing solder to seep through and create unwanted connections between layers. On the other hand, if the soldermask is too thick, it can cause issues with via registration and alignment, leading to incomplete or misaligned via plugging.

Recommended Soldermask Thickness

The recommended soldermask thickness depends on various factors, such as the PCB application, design requirements, and manufacturing capabilities. The following table provides a general guideline for soldermask thickness based on different PCB types:

| PCB Type | Recommended Soldermask Thickness |

|---|---|

| Standard PCB | 0.8 – 1.2 mils (20 – 30 µm) |

| High-density interconnect (HDI) PCB | 0.5 – 0.8 mils (12 – 20 µm) |

| Flex PCB | 0.4 – 0.6 mils (10 – 15 µm) |

| Rigid-flex PCB | 0.6 – 1.0 mils (15 – 25 µm) |

It is important to note that these values are general recommendations, and the actual soldermask thickness may vary depending on the specific requirements of the PCB design and the capabilities of the PCB manufacturer. Designers should consult with their PCB fabrication partner to determine the optimal soldermask thickness for their specific application.

Frequently Asked Questions (FAQ)

1. What is the purpose of soldermask on a PCB?

Soldermask serves several purposes on a PCB, including protecting the copper traces from oxidation, preventing solder bridges, providing electrical insulation, and enhancing the visual appearance of the board.

2. How does soldermask thickness affect PCB performance?

Soldermask thickness can impact PCB performance in various ways, such as influencing impedance control, signal integrity, and thermal management. Thicker soldermask layers can increase impedance and capacitance, while thinner layers may not provide sufficient insulation or protection.

3. What are the common methods for applying soldermask to a PCB?

The two primary methods for applying soldermask are liquid photoimageable soldermask (LPISM) and dry film soldermask (DFSM). LPISM involves applying a liquid coating and exposing it to UV light, while DFSM uses a dry film that is laminated onto the PCB surface.

4. How does soldermask thickness affect the manufacturing process?

Soldermask thickness can impact various manufacturing aspects, such as solder paste printing, component assembly, and via plugging. Thickness variations can lead to issues with solder paste release, component misalignment, and incomplete via plugging.

5. What is the recommended soldermask thickness for different types of PCBs?

The recommended soldermask thickness varies depending on the PCB type. Standard PCBs typically have a soldermask thickness of 0.8 – 1.2 mils (20 – 30 µm), while HDI PCBs, flex PCBs, and rigid-flex PCBs may have thinner soldermask layers. However, the actual thickness should be determined based on the specific design requirements and manufacturer capabilities.

Conclusion

Soldermask thickness is a critical factor in PCB design and manufacturing, as it can significantly impact the performance, reliability, and manufacturability of the board. Designers must carefully consider the soldermask thickness in relation to various aspects, such as impedance control, signal integrity, thermal management, and manufacturing processes. By selecting the appropriate soldermask thickness and working closely with PCB fabrication partners, designers can ensure optimal PCB performance and successful manufacturing outcomes.

Leave a Reply