Introduction to PCB Fabrication

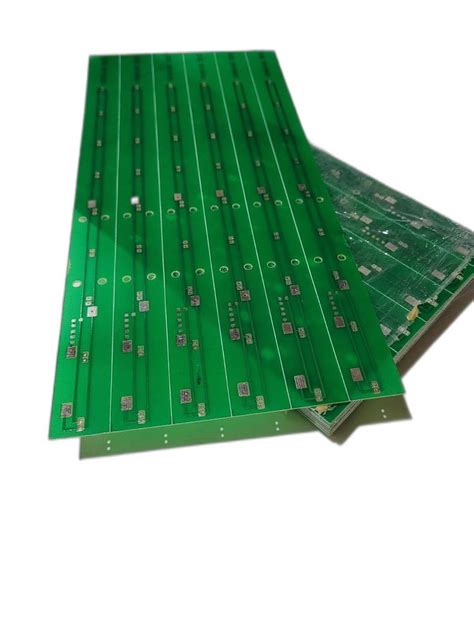

Printed Circuit Board (PCB) fabrication is a complex process that involves multiple steps and specialized equipment. The quality and reliability of the PCB depend heavily on the equipment used in the manufacturing process. RAYMING, a leading PCB manufacturer, ensures the highest standards of quality by using audited PCB fabrication equipment.

What is PCB Fabrication?

PCB fabrication is the process of creating a printed circuit board, which is used to mechanically support and electrically connect electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate.

Steps in PCB Fabrication

The PCB fabrication process involves several steps, including:

- Design and Layout

- Material Selection

- Copper Clad Lamination

- Drilling

- Plating

- Etching

- Solder Mask Application

- Silkscreen Printing

- Surface Finish Application

- Electrical Testing

- Cutting and Routing

Audited PCB Fabrication Equipment at RAYMING

RAYMING uses state-of-the-art, audited equipment in each step of the PCB fabrication process to ensure the highest quality and reliability of the final product.

Design and Layout Equipment

- Computer-Aided Design (CAD) Software

- High-Performance Workstations

Material Selection Equipment

- Automated Material Handling Systems

- Moisture Analyzers

Copper Clad Lamination Equipment

- Automated Lamination Presses

- Vacuum Lamination Systems

Drilling Equipment

- CNC Drilling Machines

- Laser Drilling Machines

Plating Equipment

- Vertical Continuous Plating Lines

- Horizontal Plating Systems

Etching Equipment

- Conveyorized Spray Etchers

- Horizontal Etchin Machines

Solder Mask Application Equipment

- Vertical Screen Printing Machines

- Curtain Coating Systems

Silkscreen Printing Equipment

- Automatic Screen Printers

- UV Curing Systems

Surface Finish Application Equipment

- Horizontal Immersion Tin Plating Lines

- ENIG (Electroless Nickel Immersion Gold) Plating Systems

Electrical Testing Equipment

- Flying Probe Testers

- Automated Optical Inspection (AOI) Systems

Cutting and Routing Equipment

- CNC Routers

- Depaneling Machines

Benefits of Using Audited PCB Fabrication Equipment

Using audited PCB fabrication equipment offers several benefits, including:

-

Improved Quality: Audited equipment ensures that the PCBs meet the highest standards of quality and reliability.

-

Increased Efficiency: Automated equipment helps streamline the manufacturing process, reducing lead times and increasing productivity.

-

Reduced Human Error: By minimizing human intervention, audited equipment reduces the risk of errors and inconsistencies in the final product.

-

Cost Savings: Efficient and reliable equipment can help reduce production costs, ultimately leading to cost savings for the customer.

-

Compliance with Industry Standards: Audited equipment ensures that the PCBs comply with various industry standards, such as IPC, UL, and RoHS.

Comparison of Audited vs. Non-Audited PCB Fabrication Equipment

| Factor | Audited Equipment | Non-Audited Equipment |

|---|---|---|

| Quality | High | Variable |

| Reliability | High | Variable |

| Efficiency | High | Low to Moderate |

| Human Error | Minimal | Higher Risk |

| Cost | Higher Initial Investment, Lower Long-Term Costs | Lower Initial Investment, Higher Long-Term Costs |

| Compliance | Meets Industry Standards | May Not Meet Industry Standards |

RAYMING’s Commitment to Quality

RAYMING is committed to providing its customers with the highest quality PCBs. By investing in audited PCB fabrication equipment and maintaining strict quality control measures, RAYMING ensures that every PCB meets or exceeds industry standards and customer expectations.

ISO Certifications

RAYMING is ISO 9001:2015 and ISO 14001:2015 certified, demonstrating its commitment to quality management and environmental responsibility.

IPC Standards

All PCBs manufactured by RAYMING comply with the relevant IPC standards, ensuring consistency and reliability in the final product.

Continuous Improvement

RAYMING continuously invests in new technologies and equipment to improve its manufacturing processes and maintain its position as a leader in the PCB industry.

Frequently Asked Questions (FAQ)

- What is the difference between audited and non-audited PCB fabrication equipment?

-

Audited equipment has been inspected and certified to meet specific quality and performance standards, while non-audited equipment may not have undergone the same rigorous testing and certification process.

-

How does using audited equipment benefit the customer?

-

Using audited equipment ensures that the PCBs are of the highest quality and reliability, reducing the risk of defects and failures. This can lead to cost savings and improved product performance for the customer.

-

What certifications and standards does RAYMING comply with?

-

RAYMING is ISO 9001:2015 and ISO 14001:2015 certified and complies with relevant IPC standards in its PCB manufacturing processes.

-

How often does RAYMING update its PCB fabrication equipment?

-

RAYMING continuously invests in new technologies and equipment to improve its manufacturing processes and maintain its position as a leader in the PCB industry.

-

Can RAYMING accommodate custom PCB designs and specifications?

- Yes, RAYMING has the expertise and equipment to accommodate a wide range of custom PCB designs and specifications, working closely with customers to ensure their requirements are met.

Conclusion

RAYMING’s commitment to using audited PCB fabrication equipment sets it apart as a leader in the industry. By investing in state-of-the-art equipment and maintaining strict quality control measures, RAYMING ensures that every PCB meets the highest standards of quality and reliability. This commitment to excellence benefits customers through improved product performance, reduced risk of defects, and potential cost savings. As the PCB industry continues to evolve, RAYMING remains at the forefront, continuously adapting and innovating to meet the changing needs of its customers.

Leave a Reply