Introduction to Dielectric Constant

A dielectric constant, also known as the relative permittivity, is a measure of how easily a material can become polarized by imposition of an electric field on an insulating material. It is the ratio of the permittivity of a substance to the permittivity of free space. It is an essential property of an electrical insulating material. The dielectric constant is a dimensionless number and is always greater than or equal to 1.

The dielectric constant (εᵣ) can be expressed as:

εᵣ = ε / ε₀

Where:

– ε is the permittivity of the material

– ε₀ is the permittivity of free space (vacuum) which has a value of 8.854 x 10⁻¹² F/m.

A material with a high dielectric constant is a good electrical insulator and can store a large amount of energy in an electric field. On the other hand, a material with a low dielectric constant is a poor electrical insulator and does not store much energy in an electric field.

Factors Affecting Dielectric Constant

Several factors can affect the dielectric constant of a material:

-

Temperature: The dielectric constant of a material changes with temperature. In general, the dielectric constant decreases with increasing temperature.

-

Frequency: The dielectric constant of a material also changes with frequency. At high frequencies, the dielectric constant is lower than at low frequencies.

-

Moisture Content: The presence of moisture in a material can significantly increase its dielectric constant.

-

Density: The dielectric constant of a material is directly proportional to its density. A higher density results in a higher dielectric constant.

-

Chemical Composition: The chemical composition of a material also affects its dielectric constant. Polar molecules have a higher dielectric constant than non-polar molecules.

Dielectric Materials

A dielectric material is an electrical insulator that can be polarized by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the material, as in a conductor, but only slightly shift from their average equilibrium positions causing dielectric polarization. Because of dielectric polarization, positive charges are displaced in the direction of the field and negative charges shift in the opposite direction. This creates an internal electric field that reduces the overall field within the dielectric itself.

Dielectric materials are essential in many applications, such as capacitors, high-voltage insulators, and microwave devices. They are used to store electrical energy, insulate conductors, and modify the propagation of electromagnetic waves.

Types of Dielectric Materials

There are several types of dielectric materials, each with unique properties and applications:

-

Ceramic Dielectrics: Ceramic dielectrics are inorganic, non-metallic materials that are composed of metal oxides, nitrides, or carbides. They have high dielectric constants, low dielectric loss, and excellent thermal stability. Examples include barium titanate (BaTiO₃), aluminum oxide (Al₂O₃), and silicon nitride (Si₃N₄).

-

Polymer Dielectrics: Polymer dielectrics are organic materials composed of long chains of repeating units. They have lower dielectric constants than ceramic dielectrics but are more flexible and easier to process. Examples include polyethylene (PE), polypropylene (PP), and polytetrafluoroethylene (PTFE or Teflon).

-

Glass Dielectrics: Glass dielectrics are amorphous materials composed of silicon dioxide (SiO₂) and other metal oxides. They have moderate dielectric constants, low dielectric loss, and good thermal stability. Examples include soda-lime glass and borosilicate glass.

-

Mica Dielectrics: Mica dielectrics are naturally occurring minerals composed of silicate materials. They have high dielectric strength, low dielectric loss, and excellent thermal stability. Mica is often used in high-voltage capacitors and insulators.

-

Composite Dielectrics: Composite dielectrics are materials composed of two or more distinct phases, such as a polymer matrix filled with ceramic particles. They combine the properties of the individual components to achieve desired dielectric properties. Examples include barium titanate-filled polyethylene and aluminum oxide-filled epoxy.

Properties of Dielectric Materials

Dielectric materials have several key properties that determine their suitability for various applications:

-

Dielectric Constant: As discussed earlier, the dielectric constant is a measure of a material’s ability to store electrical energy in an electric field. Materials with high dielectric constants are good for capacitors and energy storage applications.

-

Dielectric Strength: Dielectric strength is the maximum electric field that a material can withstand before breaking down and becoming conductive. It is an important property for high-voltage insulators and capacitors.

-

Dielectric Loss: Dielectric loss is a measure of the energy dissipated in a dielectric material when an alternating electric field is applied. Low dielectric loss is desirable for high-frequency applications, such as microwave devices and radio frequency (RF) circuits.

-

Thermal Stability: Thermal stability refers to a material’s ability to maintain its dielectric properties over a wide temperature range. Materials with good thermal stability are essential for applications in extreme environments, such as aerospace and automotive industries.

-

Mechanical Properties: Mechanical properties, such as flexibility, strength, and durability, are important for dielectric materials used in structural applications, such as insulators and printed circuit boards.

Applications of Dielectric Materials

Dielectric materials have numerous applications in various fields, including electronics, energy storage, and telecommunications:

-

Capacitors: Dielectric materials are used as the insulating layer between the conductive plates in capacitors. The dielectric constant of the material determines the capacitance of the device. High-dielectric-constant materials, such as ceramic dielectrics, are used in small, high-capacitance capacitors for energy storage and filtering applications.

-

Insulators: Dielectric materials with high dielectric strength are used as insulators in high-voltage applications, such as power transmission lines, transformers, and switchgear. Ceramic and glass dielectrics are commonly used for these purposes.

-

Printed Circuit Boards (PCBs): Dielectric materials are used as the substrate in PCBs to provide mechanical support and electrical insulation between conductive traces. Glass-reinforced epoxy (FR-4) is the most widely used dielectric material for PCBs.

-

Microwave Devices: Dielectric materials with low dielectric loss are used in microwave devices, such as antennas, filters, and resonators. Ceramic dielectrics, such as aluminum oxide and magnesium titanate, are commonly used in these applications.

-

Sensors: Dielectric materials with temperature-dependent or pressure-dependent dielectric constants are used in sensors for measuring temperature, pressure, and other physical quantities. Ferroelectric ceramics, such as barium titanate and lead zirconate titanate (PZT), are used in piezoelectric sensors and actuators.

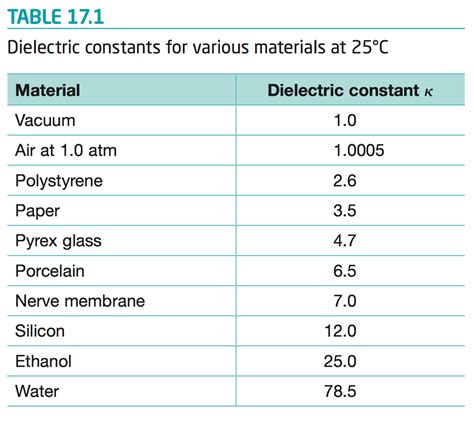

Dielectric Constant Table

The following table lists the dielectric constants of some common materials at room temperature:

| Material | Dielectric Constant (εᵣ) |

|---|---|

| Vacuum | 1.0 |

| Air | 1.0006 |

| Teflon (PTFE) | 2.1 |

| Polyethylene (PE) | 2.3 |

| Polypropylene (PP) | 2.2-2.4 |

| Paper | 2.5-3.5 |

| Glass | 4.0-10.0 |

| Mica | 5.4-8.7 |

| Aluminum Oxide (Al₂O₃) | 9.0-10.1 |

| Silicon Dioxide (SiO₂) | 3.9 |

| Barium Titanate (BaTiO₃) | 1,000-10,000 |

FAQ

1. What is the difference between dielectric constant and dielectric strength?

The dielectric constant is a measure of a material’s ability to store electrical energy in an electric field, while dielectric strength is the maximum electric field that a material can withstand before breaking down and becoming conductive. A high dielectric constant does not necessarily mean a high dielectric strength, and vice versa.

2. Can the dielectric constant of a material change with frequency?

Yes, the dielectric constant of a material can change with frequency. At high frequencies, the dielectric constant is generally lower than at low frequencies due to the inability of the polarization mechanisms to keep up with the rapidly changing electric field.

3. Why are ceramic dielectrics widely used in capacitors?

Ceramic dielectrics, such as barium titanate, have very high dielectric constants (up to 10,000) and can store a large amount of electrical energy in a small volume. This makes them ideal for use in small, high-capacitance capacitors for energy storage and filtering applications.

4. What is the role of dielectric materials in printed circuit boards (PCBs)?

In PCBs, dielectric materials serve as the substrate, providing mechanical support and electrical insulation between conductive traces. The most common dielectric material used in PCBs is glass-reinforced epoxy (FR-4), which has good mechanical strength, thermal stability, and dielectric properties.

5. How do temperature and moisture affect the dielectric constant of a material?

The dielectric constant of a material generally decreases with increasing temperature due to the reduced ability of the polarization mechanisms to respond to the electric field at higher temperatures. The presence of moisture in a material can significantly increase its dielectric constant because water has a high dielectric constant (around 80) compared to most other materials.

Conclusion

The dielectric constant and dielectric materials are essential concepts in the field of electrical engineering and materials science. The dielectric constant is a measure of a material’s ability to store electrical energy in an electric field, while dielectric materials are electrical insulators that can be polarized by an applied electric field. Dielectric materials have numerous applications, including capacitors, insulators, printed circuit boards, microwave devices, and sensors. The choice of a dielectric material for a specific application depends on its dielectric properties, such as dielectric constant, dielectric strength, dielectric loss, thermal stability, and mechanical properties. Understanding the properties and behavior of dielectric materials is crucial for designing and optimizing electrical and electronic devices.

Leave a Reply