Introduction to PCB Gerber Conversion

Printed Circuit Board (PCB) design is a crucial aspect of electronic product development. The process involves creating a layout of the electronic components and their interconnections on a board. Once the design is finalized, it needs to be converted into a format that can be understood by the manufacturing equipment. This is where Gerber files come into play.

Gerber files are the industry standard for PCB manufacturing. They contain all the necessary information required to fabricate a PCB, including the copper layers, solder mask, silkscreen, and drill data. However, designing a PCB layout in a PDF format is a common practice among designers. In such cases, converting the PDF to Gerber format becomes essential for manufacturing.

In this article, we will explore the various methods of converting PDF to Gerber for PCB layout. We will also discuss the best practices and tools available for PCB Gerber conversion.

What is a Gerber File?

A Gerber file is a standard file format used in PCB manufacturing. It is named after the Gerber Scientific Instrument Company, which developed the format in the 1960s. Gerber files are used to describe the printed circuit board images, which include copper layers, solder mask, silkscreen, and drill data.

Gerber files are ASCII text files that contain commands for drawing the PCB layout. Each command specifies a particular operation, such as moving to a specific location, drawing a line or arc, or defining an aperture. The aperture defines the shape and size of the drawing tool used to create the image.

Gerber files are essential for PCB manufacturing because they provide a standardized way of communicating the PCB design to the fabrication process. They ensure that the manufactured PCB matches the original design intent, without any errors or discrepancies.

Why Convert PDF to Gerber?

PDF (Portable Document Format) is a widely used file format for sharing documents, including PCB layouts. Many PCB designers prefer to create their layouts in PDF format because it is easy to share and view on different devices and platforms.

However, PDF files are not suitable for PCB manufacturing because they do not contain the necessary information required for fabrication. PDF files are essentially images of the PCB layout, without any information about the layers, apertures, or drill data.

To manufacture a PCB, the design needs to be converted into Gerber format. Gerber files contain all the necessary information required for fabrication, including the copper layers, solder mask, silkscreen, and drill data. They are the industry standard for PCB manufacturing and are understood by all fabrication houses.

Converting PDF to Gerber ensures that the PCB design can be manufactured accurately and efficiently. It also helps to avoid any errors or discrepancies that may arise from using a non-standard file format.

Methods of Converting PDF to Gerber

There are several methods available for converting PDF to Gerber format. Let’s take a look at some of the most common methods:

1. Using PCB Design Software

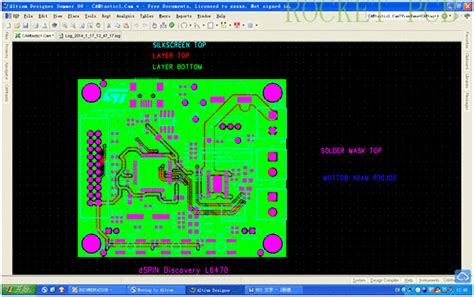

The most common method of converting PDF to Gerber is by using PCB design software. Most PCB design tools, such as Altium Designer, Eagle, and KiCad, have built-in features for importing PDF files and converting them into Gerber format.

To convert a PDF to Gerber using PCB design software, follow these steps:

- Open the PCB design software and create a new project.

- Import the PDF file into the software. This can usually be done by selecting “File” > “Import” and choosing the PDF file.

- The software will convert the PDF into a PCB layout. You may need to adjust the settings, such as the layer mapping and drill sizes, to ensure that the layout is accurate.

- Once the layout is finalized, export the design as Gerber files. This can usually be done by selecting “File” > “Export” and choosing the Gerber format.

Using PCB design software to convert PDF to Gerber has several advantages. It allows for greater control over the conversion process and enables the designer to make any necessary adjustments to the layout. It also ensures that the Gerber files are generated accurately and meet the manufacturing requirements.

However, using PCB design software for PDF to Gerber conversion can be time-consuming and requires a certain level of expertise. It may not be the most efficient method for simple or low-volume PCB designs.

2. Using Online Conversion Tools

Another method of converting PDF to Gerber is by using online conversion tools. There are several websites that offer free or paid services for converting PDF to Gerber format.

To use an online conversion tool, follow these steps:

- Upload the PDF file to the website.

- Select the layer mapping and other settings, such as the drill sizes and apertures.

- Download the generated Gerber files.

Online conversion tools are a quick and easy way to convert PDF to Gerber, especially for simple or low-volume PCB designs. They do not require any specialized software or expertise and can be accessed from any device with an internet connection.

However, online conversion tools may not offer the same level of control and accuracy as PCB design software. They may also have limitations on the file size or the number of conversions allowed per day.

Some popular online conversion tools for PDF to Gerber include:

- PCB Unlimited: Offers free PDF to Gerber conversion with a file size limit of 5MB.

- PCB2Gerber: Offers paid PDF to Gerber conversion with no file size limit and support for multi-page PDFs.

- PCBWay: Offers free PDF to Gerber conversion with a file size limit of 10MB.

3. Using CAM Software

Another method of converting PDF to Gerber is by using Computer-Aided Manufacturing (CAM) software. CAM software is specialized software used for preparing PCB designs for manufacturing.

To convert a PDF to Gerber using CAM software, follow these steps:

- Import the PDF file into the CAM software.

- Define the layer mapping and other settings, such as the drill sizes and apertures.

- Generate the Gerber files.

CAM software offers a high level of control and accuracy for PDF to Gerber conversion. It allows for fine-tuning the settings and ensuring that the Gerber files meet the manufacturing requirements.

However, CAM software can be expensive and requires specialized knowledge to use effectively. It may not be the most efficient method for simple or low-volume PCB designs.

Some popular CAM software for PDF to Gerber conversion include:

- GenCAM: Offers a range of features for PCB manufacturing, including PDF to Gerber conversion.

- CAMtastic: Offers a user-friendly interface for PDF to Gerber conversion and other PCB manufacturing tasks.

- FABmaster: Offers a comprehensive solution for PCB manufacturing, including PDF to Gerber conversion and automatic layer recognition.

Best Practices for PCB Gerber Conversion

To ensure that the PCB Gerber conversion process is accurate and efficient, follow these best practices:

1. Use High-Quality PDF Files

The quality of the PDF file can affect the accuracy of the Gerber conversion. Ensure that the PDF file is high-resolution and free from any distortions or artifacts. If possible, use vector-based PDF files instead of raster-based files.

2. Define the Layer Mapping

PCB designs typically have multiple layers, such as copper, solder mask, and silkscreen. When converting PDF to Gerber, it is important to define the layer mapping correctly. Ensure that each layer in the PDF file is mapped to the corresponding layer in the Gerber file.

3. Set the Correct Aperture Sizes

Apertures define the shape and size of the drawing tool used to create the PCB image. When converting PDF to Gerber, ensure that the aperture sizes are set correctly. This will ensure that the PCB is manufactured with the correct trace widths and pad sizes.

4. Verify the Drill Data

Drill data is an essential part of the PCB manufacturing process. When converting PDF to Gerber, ensure that the drill data is included and verified. This includes the drill sizes, locations, and plated/non-plated status.

5. Use a Gerber Viewer

After generating the Gerber files, use a Gerber viewer to verify that the files are accurate and complete. A Gerber viewer allows you to see the PCB layout in its final form and check for any errors or discrepancies.

Some popular Gerber viewers include:

- ViewMate: Offers a free online Gerber viewer with support for multiple file formats.

- GC-Prevue: Offers a free standalone Gerber viewer with support for multiple file formats and 3D viewing.

- Gerber X2 Viewer: Offers a free online Gerber viewer with support for the latest Gerber X2 format.

| Tool | Features |

|---|---|

| PCB Design Software | High level of control and accuracy, but requires specialized knowledge and can be time-consuming |

| Online Conversion Tools | Quick and easy to use, but may have limitations on file size and conversion options |

| CAM Software | High level of control and accuracy, but can be expensive and requires specialized knowledge |

Frequently Asked Questions (FAQ)

1. What is the difference between a PDF and a Gerber file?

A PDF file is a widely used file format for sharing documents, including PCB layouts. It is essentially an image of the PCB layout, without any information about the layers, apertures, or drill data. On the other hand, a Gerber file is a standard file format used in PCB manufacturing. It contains all the necessary information required to fabricate a PCB, including the copper layers, solder mask, silkscreen, and drill data.

2. Can I use any PDF file for PCB Gerber conversion?

Not all PDF files are suitable for PCB Gerber conversion. The PDF file should be high-resolution and free from any distortions or artifacts. Vector-based PDF files are preferred over raster-based files. The PDF file should also contain all the necessary layers and information required for PCB manufacturing.

3. How long does it take to convert a PDF to Gerber?

The time required for PDF to Gerber conversion depends on the complexity of the PCB design and the method used for conversion. Using PCB design software or CAM software may take longer than using online conversion tools, but it offers greater control and accuracy. On average, PDF to Gerber conversion can take anywhere from a few minutes to a few hours.

4. Can I convert a Gerber file back to PDF?

Yes, it is possible to convert a Gerber file back to PDF using specialized software. However, the resulting PDF file may not be an exact replica of the original PCB layout and may not be suitable for further editing or modification.

5. What should I do if I encounter errors during PCB Gerber conversion?

If you encounter errors during PCB Gerber conversion, the first step is to verify that the PDF file is suitable for conversion and contains all the necessary information. If the problem persists, try using a different conversion method or tool. If you are using PCB design software or CAM software, consult the user manual or seek assistance from the software provider’s support team.

Conclusion

Converting PDF to Gerber is a critical step in the PCB manufacturing process. It ensures that the PCB design can be accurately and efficiently manufactured by the fabrication house. There are several methods available for PDF to Gerber conversion, including using PCB design software, online conversion tools, and CAM software.

To ensure that the PCB Gerber conversion process is accurate and efficient, it is important to follow best practices such as using high-quality PDF files, defining the layer mapping correctly, setting the correct aperture sizes, verifying the drill data, and using a Gerber viewer to check the final output.

By understanding the different methods and best practices for PCB Gerber conversion, PCB designers can streamline their workflow and ensure that their designs are manufactured to the highest standards of quality and reliability.

Leave a Reply