Introduction to PCB Warpage Measurement

Printed Circuit Board (PCB) warpage is a critical issue in the electronics manufacturing industry. It can lead to a variety of problems, such as component misalignment, poor solder joint reliability, and even complete assembly failure. As PCB designs become more complex and the demand for higher reliability increases, it is essential to accurately measure and control PCB warpage during the reflow process.

The IPC-9641 standard, released in 2020, provides guidelines for measuring PCB warpage during reflow. This standard aims to establish a consistent and reliable method for evaluating PCB warpage, enabling manufacturers to improve their processes and ensure the quality of their products.

In this article, we will discuss the importance of measuring PCB warpage during reflow, the key aspects of the IPC-9641 standard, and how to implement it in your manufacturing process.

Why Measure PCB Warpage during Reflow?

The Impact of PCB Warpage on Assembly Quality

PCB warpage can have a significant impact on the quality of the final assembled product. Some of the main issues caused by excessive PCB warpage include:

- Component misalignment

- Poor solder joint formation

- Increased stress on components

- Reduced reliability of the assembled product

By measuring and controlling PCB warpage during reflow, manufacturers can minimize these issues and improve the overall quality of their products.

The Relationship between PCB Warpage and Reflow Profile

The reflow profile plays a crucial role in determining the extent of PCB warpage during the assembly process. Factors such as peak temperature, ramp rates, and time above liquidus (TAL) can all contribute to PCB warpage.

Measuring PCB warpage during reflow allows manufacturers to optimize their reflow profiles to minimize warpage and ensure consistent results.

Key Aspects of the IPC-9641 Standard

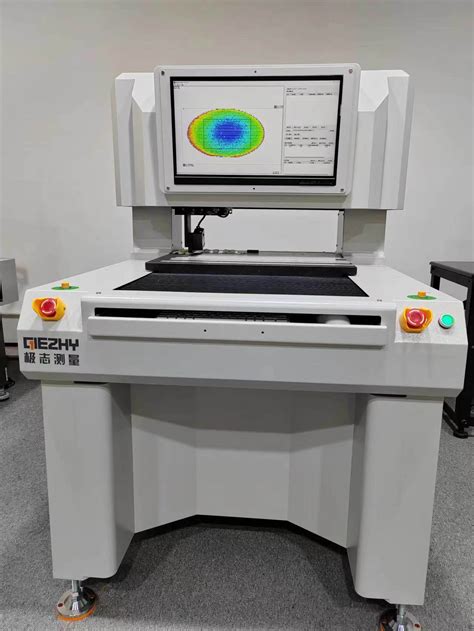

Measurement Equipment and Setup

The IPC-9641 standard specifies the requirements for the measurement equipment and setup used to evaluate PCB warpage during reflow. Some of the key requirements include:

- Use of a non-contact measurement system, such as a shadow moiré or fringe projection system

- Minimum measurement accuracy of ±20 μm

- Ability to measure warpage at multiple points across the PCB surface

- Capability to measure warpage at various temperatures during the reflow process

Measurement Procedure and Data Analysis

The IPC-9641 standard also outlines the measurement procedure and data analysis methods for evaluating PCB warpage during reflow. The main steps include:

- Preparing the PCB sample and measurement system

- Measuring the initial (pre-reflow) warpage profile

- Measuring the warpage profile at various points during the reflow process

- Analyzing the data to determine the maximum warpage and warpage range

- Comparing the results to the specified warpage limits

Warpage Limits and Acceptance Criteria

The IPC-9641 standard provides guidance on establishing warpage limits and acceptance criteria based on the specific requirements of the application. Factors to consider when setting these limits include:

- PCB size and thickness

- Component types and sizes

- Solder joint reliability requirements

- Assembly process capabilities

Manufacturers should work closely with their customers and suppliers to determine the appropriate warpage limits for their products.

Implementing IPC-9641 in Your Manufacturing Process

Integrating Warpage Measurement into Quality Control

To effectively control PCB warpage during reflow, it is essential to integrate warpage measurement into your quality control process. This can be done by:

- Establishing a regular schedule for measuring PCB warpage during reflow

- Defining clear warpage limits and acceptance criteria

- Implementing a system for tracking and analyzing warpage data over time

- Using the data to identify trends and make process improvements

Optimizing Reflow Profiles to Minimize Warpage

By analyzing the warpage data collected during the measurement process, manufacturers can optimize their reflow profiles to minimize PCB warpage. This may involve adjusting parameters such as:

- Peak temperature

- Ramp rates

- Time above liquidus (TAL)

- Cooling rate

It is important to balance the need to minimize warpage with other requirements, such as solder joint formation and component reliability.

Collaborating with Suppliers and Customers

Effective control of PCB warpage during reflow requires collaboration between manufacturers, suppliers, and customers. This includes:

- Working with PCB Suppliers to ensure that the board design and materials are optimized for minimal warpage

- Collaborating with component suppliers to select packages that are less susceptible to warpage-related issues

- Engaging with customers to establish clear warpage limits and acceptance criteria based on the specific needs of the application

By fostering open communication and collaboration throughout the supply chain, manufacturers can more effectively address the challenges of PCB warpage during reflow.

Frequently Asked Questions (FAQ)

-

What is PCB warpage, and why is it important to measure it during reflow?

PCB warpage refers to the distortion or bending of a printed circuit board during the reflow process. It is important to measure PCB warpage during reflow because excessive warpage can lead to component misalignment, poor solder joint formation, and reduced reliability of the assembled product. -

What are the main benefits of using the IPC-9641 standard for measuring PCB warpage during reflow?

The main benefits of using the IPC-9641 standard include: - Establishing a consistent and reliable method for evaluating PCB warpage

- Providing guidance on measurement equipment, procedures, and data analysis

- Helping manufacturers to set appropriate warpage limits and acceptance criteria

-

Enabling process optimization and improvement based on warpage data

-

What types of measurement equipment are recommended by the IPC-9641 standard for measuring PCB warpage during reflow?

The IPC-9641 standard recommends using non-contact measurement systems, such as shadow moiré or fringe projection systems, for measuring PCB warpage during reflow. These systems should have a minimum measurement accuracy of ±20 μm and be capable of measuring warpage at multiple points across the PCB surface and at various temperatures during the reflow process. -

How can manufacturers integrate PCB warpage measurement into their quality control processes?

Manufacturers can integrate PCB warpage measurement into their quality control processes by establishing a regular schedule for measuring warpage during reflow, defining clear warpage limits and acceptance criteria, implementing a system for tracking and analyzing warpage data over time, and using the data to identify trends and make process improvements. -

What role does collaboration play in effectively controlling PCB warpage during reflow?

Collaboration between manufacturers, suppliers, and customers is essential for effectively controlling PCB warpage during reflow. This includes working with PCB suppliers to optimize board design and materials, collaborating with component suppliers to select packages that are less susceptible to warpage-related issues, and engaging with customers to establish clear warpage limits and acceptance criteria based on the specific needs of the application. Open communication and collaboration throughout the supply chain can help manufacturers more effectively address the challenges of PCB warpage during reflow.

Conclusion

Measuring PCB warpage during reflow is crucial for ensuring the quality and reliability of assembled products in the electronics manufacturing industry. The IPC-9641 standard provides a comprehensive framework for evaluating PCB warpage, helping manufacturers to establish consistent and reliable measurement practices.

By integrating warpage measurement into their quality control processes, optimizing reflow profiles based on warpage data, and collaborating with suppliers and customers, manufacturers can effectively control PCB warpage during reflow and improve the overall performance of their products.

As the electronics industry continues to evolve, with increasingly complex PCB designs and higher reliability requirements, the importance of measuring PCB warpage during reflow will only continue to grow. By adopting the IPC-9641 standard and implementing best practices for warpage control, manufacturers can position themselves for success in this challenging and dynamic market.

| Aspect | Key Points |

|---|---|

| Measurement Equipment | – Non-contact measurement systems (shadow moiré or fringe projection) – Minimum measurement accuracy of ±20 μm – Ability to measure warpage at multiple points across PCB surface – Capability to measure warpage at various temperatures during reflow |

| Measurement Procedure | 1. Prepare PCB sample and measurement system 2. Measure initial (pre-reflow) warpage profile 3. Measure warpage profile at various points during reflow 4. Analyze data to determine maximum warpage and warpage range 5. Compare results to specified warpage limits |

| Warpage Limits | Factors to consider: – PCB size and thickness – Component types and sizes – Solder joint reliability requirements – Assembly process capabilities |

| Integration into QC | – Establish regular schedule for measuring warpage during reflow – Define clear warpage limits and acceptance criteria – Implement system for tracking and analyzing warpage data over time – Use data to identify trends and make process improvements |

| Reflow Optimization | Adjust parameters based on warpage data: – Peak temperature – Ramp rates – Time above liquidus (TAL) – Cooling rate Balance warpage minimization with other requirements (solder joint formation, component reliability) |

| Collaboration | – Work with PCB suppliers to optimize board design and materials – Collaborate with component suppliers to select packages less susceptible to warpage – Engage with customers to establish clear warpage limits and acceptance criteria based on application needs – Foster open communication and collaboration throughout supply chain |

Leave a Reply