Introduction to PCB Manufacturing

Printed Circuit Board (PCB) manufacturing is a critical process in the electronics industry. PCBs are the backbone of modern electronic devices, connecting and supporting various components to create functional circuits. Shengyi Technology Co., Ltd. is a leading PCB manufacturer and fabricator based in China, known for its high-quality products and advanced manufacturing capabilities.

What is PCB Manufacturing?

PCB manufacturing is the process of creating printed circuit boards that are used in electronic devices. The process involves several steps, including:

- Design: Creating the PCB layout using specialized software

- Printing: Transferring the design onto the copper-clad board

- Etching: Removing unwanted copper from the board

- Drilling: Creating holes for components and vias

- Plating: Applying a layer of metal to the holes and traces

- Solder Mask: Applying a protective layer over the copper traces

- Silkscreen: Adding text and symbols for component placement

- Testing: Verifying the functionality and quality of the PCB

Types of PCBs

There are several types of PCBs, each with its own unique features and applications:

| PCB Type | Layers | Applications |

|---|---|---|

| Single-sided | 1 | Simple circuits, low-cost devices |

| Double-sided | 2 | More complex circuits, higher component density |

| Multi-layer | 3+ | High-density circuits, advanced electronic devices |

| Flexible | Varies | Wearable electronics, compact devices |

| Rigid-Flex | Varies | Combination of rigid and flexible sections |

Shengyi Technology Co., Ltd.

Shengyi Technology Co., Ltd. is a leading PCB manufacturer and fabricator headquartered in Dongguan, China. Founded in 1998, the company has grown to become one of the top PCB Suppliers globally, serving customers in various industries, including telecommunications, automotive, consumer electronics, and medical devices.

Company Overview

- Founded: 1998

- Headquarters: Dongguan, China

- Employees: 10,000+

- Manufacturing Facilities: 3 (Dongguan, Kunshan, and Jiangyin)

- Certifications: ISO 9001, ISO 14001, IATF 16949, UL, and more

Products and Services

Shengyi offers a wide range of PCB products and services, including:

- Single-sided, double-sided, and multi-layer PCBs

- High Density Interconnect (HDI) PCBs

- Flexible and Rigid-Flex PCBs

- Metal Core PCBs

- Speciality materials (FR4, Rogers, Polyimide, etc.)

- PCB Assembly (SMT and THT)

- PCB design and engineering support

PCB Manufacturing Process at Shengyi

Shengyi follows a strict and well-defined PCB manufacturing process to ensure consistent quality and reliability. The process can be broken down into several key steps:

1. PCB Design and Engineering

Shengyi’s experienced engineering team works closely with customers to optimize PCB designs for manufacturability, reliability, and cost-effectiveness. They use advanced design tools and simulation software to ensure the best possible results.

2. Material Selection and Preparation

Shengyi sources high-quality raw materials from trusted suppliers, including copper-clad laminates, prepregs, and solder masks. The materials are carefully inspected and prepared for the manufacturing process.

3. Imaging and Etching

The PCB design is transferred onto the copper-clad board using a photoresist and exposure process. The unwanted copper is then etched away using a chemical solution, leaving only the desired traces.

4. Drilling and Plating

Precise CNC drilling machines create holes for components and vias. The holes are then plated with copper to ensure proper electrical connectivity.

5. Solder Mask and Silkscreen

A protective solder mask is applied to the PCB, covering the copper traces while leaving the pads exposed. The silkscreen layer is then added, providing text and symbols for component placement.

6. Surface Finish

The PCB undergoes a surface finish process, such as HASL, ENIG, or OSP, to protect the exposed copper and improve solderability.

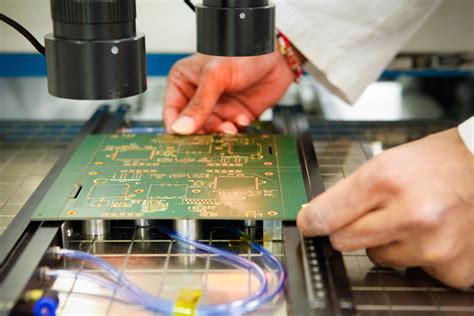

7. Testing and Inspection

Each PCB is thoroughly tested and inspected to ensure it meets the required specifications and quality standards. This includes automated optical inspection (AOI), electrical testing, and microsectioning.

Advanced PCB Manufacturing Technologies

Shengyi invests heavily in advanced PCB manufacturing technologies to stay at the forefront of the industry. Some of the key technologies employed by the company include:

HDI PCBs

High Density Interconnect (HDI) PCBs feature finer traces, smaller vias, and higher component density compared to traditional PCBs. Shengyi uses advanced manufacturing processes, such as laser drilling and sequential lamination, to produce high-quality HDI PCBs.

Flexible and Rigid-Flex PCBs

Flexible PCBs are made from thin, flexible materials that allow the board to bend and flex without breaking. Rigid-Flex PCBs combine flexible and rigid sections to create a single, integrated board. Shengyi has extensive experience in manufacturing both types of PCBs, using advanced materials and processes.

Metal Core PCBs

Metal Core PCBs (MCPCBs) feature a metal substrate, typically aluminum, that provides excellent thermal conductivity and heat dissipation. Shengyi manufactures MCPCBs using specialized materials and processes to ensure optimal thermal performance and reliability.

Speciality Materials

Shengyi works with a wide range of speciality materials to meet the specific requirements of different applications. These materials include:

- FR4: The most common PCB material, offering good mechanical and electrical properties

- Rogers: High-frequency materials with low dielectric loss and stable performance

- Polyimide: High-temperature materials with excellent thermal stability and flexibility

- Teflon: Low-loss materials with superior chemical resistance and high-frequency performance

Quality Assurance and Certifications

Shengyi is committed to maintaining the highest quality standards in PCB manufacturing. The company has implemented a comprehensive quality management system and holds several industry certifications, including:

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management System

- IATF 16949: Automotive Quality Management System

- UL: Underwriters Laboratories certification for safety and performance

- RoHS: Restriction of Hazardous Substances compliance

Shengyi conducts rigorous testing and inspection at every stage of the manufacturing process to ensure that all products meet or exceed customer requirements and industry standards.

PCB Assembly Services

In addition to PCB fabrication, Shengyi offers PCB assembly services to provide customers with complete turnkey solutions. The company has state-of-the-art SMT and THT assembly lines, as well as advanced inspection and testing equipment.

SMT Assembly

Surface Mount Technology (SMT) is the most common method for assembling electronic components onto PCBs. Shengyi’s SMT lines feature high-speed pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems to ensure fast and accurate assembly.

THT Assembly

Through-Hole Technology (THT) involves inserting component leads through holes in the PCB and soldering them to pads on the opposite side. Shengyi offers both manual and automated THT assembly services, depending on the specific requirements of the project.

Inspection and Testing

Shengyi employs a range of inspection and testing methods to verify the quality and functionality of assembled PCBs. These include:

- Automated Optical Inspection (AOI): High-speed camera systems that check for component placement, solder joint quality, and other visual defects

- X-Ray Inspection: Non-destructive testing that can detect hidden defects, such as voids or shorts, in solder joints

- In-Circuit Testing (ICT): Electrical testing that verifies the connectivity and functionality of individual components and circuits

- Functional Testing: End-to-end testing that ensures the assembled PCB performs as intended in its final application

Shengyi’s Competitive Advantages

Shengyi has several key competitive advantages that set it apart from other PCB manufacturers and fabricators:

-

Vertical Integration: Shengyi has in-house capabilities for every stage of the PCB manufacturing process, from design to assembly, allowing for better control over quality, cost, and lead times.

-

Advanced Technology: The company invests heavily in the latest manufacturing technologies and equipment, enabling it to produce high-quality, complex PCBs efficiently and reliably.

-

Experienced Team: Shengyi has a team of highly skilled engineers, technicians, and quality control experts with decades of combined experience in PCB manufacturing.

-

Global Presence: With three manufacturing facilities in China and sales offices worldwide, Shengyi can serve customers globally while providing local support and fast turnaround times.

-

Customer Focus: Shengyi places a strong emphasis on customer satisfaction, offering personalized service, flexible manufacturing options, and competitive pricing to meet each customer’s unique needs.

Frequently Asked Questions (FAQ)

- What is the minimum order quantity (MOQ) for PCBs at Shengyi?

-

The MOQ varies depending on the specific PCB type and requirements. For standard PCBs, the MOQ is typically 50-100 pieces. For more complex or customized PCBs, the MOQ may be higher.

-

What is the typical lead time for PCB orders?

-

Lead times depend on the complexity of the PCB, the quantity ordered, and the current production schedule. Standard PCBs can be manufactured in 5-7 days, while more complex orders may take 2-3 weeks or longer.

-

Does Shengyi offer PCB design services?

-

Yes, Shengyi has an experienced engineering team that can assist with PCB design and optimization. The company offers design for manufacturability (DFM) analysis, layout optimization, and other engineering support services.

-

What file formats does Shengyi accept for PCB design files?

-

Shengyi accepts industry-standard file formats, including Gerber files (RS-274X), ODB++, and IPC-2581. The company also accepts native CAD files from popular PCB design software, such as Altium Designer, Cadence Allegro, and Mentor Graphics PADS.

-

Does Shengyi offer PCB prototyping services?

- Yes, Shengyi offers rapid PCB prototyping services for customers who need quick turnaround times for low-volume orders. The company can produce prototypes in as little as 24-48 hours, depending on the complexity of the design and the current production schedule.

Conclusion

Shengyi Technology Co., Ltd. is a leading PCB manufacturer and fabricator that offers a complete range of PCB products and services. With advanced manufacturing technologies, a highly skilled team, and a commitment to quality and customer satisfaction, Shengyi is well-positioned to meet the evolving needs of the electronics industry.

As PCB technology continues to advance, Shengyi remains at the forefront of innovation, investing in new equipment, processes, and materials to stay ahead of the curve. Whether you need simple single-sided PCBs or complex HDI and rigid-flex boards, Shengyi has the expertise and capabilities to deliver high-quality products on time and on budget.

Leave a Reply