What is an FPGA?

An FPGA is an integrated circuit that can be programmed and reprogrammed after manufacturing to implement various digital circuits. It consists of an array of configurable logic blocks (CLBs) connected through programmable interconnects. The CLBs contain lookup tables (LUTs) and flip-flops, which can be configured to perform specific logic functions. The programmable interconnects allow the CLBs to be connected in different ways, enabling the implementation of complex digital circuits.

FPGAs offer several advantages:

- Flexibility: FPGAs can be reprogrammed multiple times, allowing designers to modify and update their designs even after the device has been manufactured.

- Rapid prototyping: With FPGAs, designers can quickly implement and test their designs, reducing the time required for prototyping.

- Lower upfront costs: FPGAs have lower upfront costs compared to ASICs, making them more suitable for low-volume production or projects with tight budgets.

However, FPGAs also have some limitations:

- Lower performance: FPGAs generally have lower performance compared to ASICs due to the overhead associated with programmable interconnects and the inherent limitations of the CLBs.

- Higher power consumption: The programmable nature of FPGAs results in higher power consumption compared to ASICs.

- Limited complexity: While FPGAs can implement complex digital circuits, they may not be suitable for extremely large and complex designs due to the limited number of CLBs and interconnects available.

What is an ASIC?

An ASIC is a custom-designed integrated circuit tailored to perform a specific function. Unlike FPGAs, ASICs are not programmable and are manufactured to implement a fixed digital circuit. The design process for an ASIC involves creating a custom layout using specialized software tools, which is then sent to a semiconductor foundry for fabrication.

ASICs offer several advantages:

- High performance: ASICs are designed to perform a specific function, allowing for highly optimized and efficient implementations that can achieve higher performance compared to FPGAs.

- Lower power consumption: Since ASICs are custom-designed for a specific function, they can be optimized for power efficiency, resulting in lower power consumption compared to FPGAs.

- Smaller form factor: ASICs can be designed to have a smaller form factor compared to FPGAs, making them suitable for applications with strict size constraints.

However, ASICs also have some disadvantages:

- Higher upfront costs: The custom design and fabrication process for ASICs requires significant upfront costs, making them more suitable for high-volume production.

- Longer time-to-market: The design and fabrication process for ASICs can take several months to a year, resulting in a longer time-to-market compared to FPGAs.

- Lack of flexibility: Once an ASIC is manufactured, its functionality cannot be modified, limiting its flexibility compared to FPGAs.

FPGA vs ASIC: Key Differences

Now that we have a basic understanding of FPGAs and ASICs, let’s compare them based on various factors:

Flexibility

FPGAs offer high flexibility as they can be reprogrammed multiple times, allowing designers to modify and update their designs even after the device has been manufactured. This makes FPGAs suitable for applications that require frequent design changes or updates. On the other hand, ASICs are not programmable and have a fixed functionality once manufactured, making them less flexible compared to FPGAs.

Performance

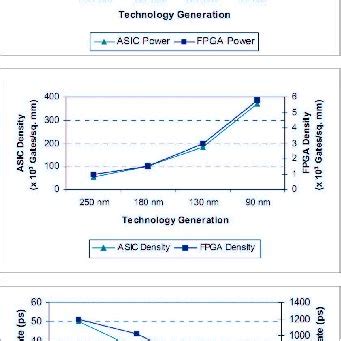

ASICs are custom-designed to perform a specific function, allowing for highly optimized and efficient implementations. As a result, ASICs can achieve higher performance compared to FPGAs. The custom layout and dedicated circuitry in ASICs enable faster processing speeds and lower latency. FPGAs, while programmable, have overhead associated with the programmable interconnects and the limitations of the CLBs, resulting in lower performance compared to ASICs.

Power Consumption

ASICs are designed to be power-efficient as they are optimized for a specific function. The custom layout and dedicated circuitry in ASICs allow for lower power consumption compared to FPGAs. FPGAs, on the other hand, have higher power consumption due to the programmable nature of the device and the overhead associated with the programmable interconnects.

Cost

FPGAs have lower upfront costs compared to ASICs. The programmable nature of FPGAs allows for faster design and prototyping, reducing the initial development costs. ASICs, on the other hand, require significant upfront costs for custom design and fabrication. However, for high-volume production, ASICs can be more cost-effective in the long run due to their lower per-unit cost.

Time-to-Market

FPGAs offer a faster time-to-market compared to ASICs. The programmable nature of FPGAs allows for rapid prototyping and design iterations, reducing the overall development time. ASICs, on the other hand, have a longer time-to-market due to the custom design and fabrication process, which can take several months to a year.

Complexity

FPGAs are suitable for implementing complex digital circuits, but they may have limitations when it comes to extremely large and complex designs. The number of available CLBs and interconnects in an FPGA can limit the maximum complexity that can be achieved. ASICs, being custom-designed, can handle higher levels of complexity and are suitable for implementing very large and complex digital circuits.

Here’s a table summarizing the key differences between FPGAs and ASICs:

| Factor | FPGA | ASIC |

|---|---|---|

| Flexibility | High, can be reprogrammed | Low, fixed functionality |

| Performance | Lower compared to ASICs | Higher, optimized for specific function |

| Power Consumption | Higher due to programmable nature | Lower, optimized for power efficiency |

| Cost | Lower upfront costs, higher per-unit cost for high volume | Higher upfront costs, lower per-unit cost for high volume |

| Time-to-Market | Faster, rapid prototyping | Longer, custom design and fabrication process |

| Complexity | Suitable for complex designs, but may have limitations for extremely large designs | Can handle higher levels of complexity, suitable for very large designs |

Choosing Between FPGA and ASIC

When deciding between an FPGA and an ASIC for your project, consider the following factors:

-

Design flexibility: If your design requires frequent modifications or updates, an FPGA might be a better choice due to its reprogrammability. However, if your design is fixed and unlikely to change, an ASIC can provide a more optimized solution.

-

Performance requirements: If your application demands high performance and fast processing speeds, an ASIC may be the preferred choice. FPGAs, while capable of implementing complex designs, may not match the performance of custom-designed ASICs.

-

Power consumption: If power efficiency is a critical concern for your application, an ASIC can provide lower power consumption compared to an FPGA. However, if power consumption is not a primary factor, an FPGA can still be a viable option.

-

Production volume: The choice between an FPGA and an ASIC often depends on the expected production volume. For low to medium volume production, FPGAs are more cost-effective due to their lower upfront costs and faster time-to-market. For high-volume production, ASICs become more cost-effective in the long run due to their lower per-unit cost.

-

Time-to-market: If you need to bring your product to market quickly, an FPGA offers a faster development cycle and shorter time-to-market. The programmability of FPGAs allows for rapid prototyping and design iterations. ASICs, on the other hand, have a longer development cycle due to the custom design and fabrication process.

-

Budget: Consider your project budget when choosing between an FPGA and an ASIC. FPGAs have lower upfront costs and are more suitable for projects with limited budgets. ASICs require significant upfront investment for custom design and fabrication, making them more suitable for projects with larger budgets and high-volume production.

Real-World Applications

FPGAs and ASICs find applications in various domains, including:

-

Aerospace and Defense: FPGAs are commonly used in aerospace and defense applications due to their flexibility and ability to be reprogrammed in the field. They are used in radar systems, satellite communication, and avionics.

-

Automotive: ASICs are widely used in the automotive industry for implementing specific functions such as engine control, power management, and sensor processing. The high performance and power efficiency of ASICs make them suitable for automotive applications.

-

Consumer Electronics: FPGAs and ASICs are used in consumer electronics devices such as smartphones, tablets, and gaming consoles. FPGAs are often used for prototyping and low-volume production, while ASICs are used for high-volume production to achieve cost and power efficiency.

-

Medical Devices: FPGAs are used in medical devices for functions such as signal processing, image processing, and real-time monitoring. The flexibility and rapid prototyping capabilities of FPGAs make them suitable for medical device development.

-

Data Centers: FPGAs are increasingly being used in data centers for accelerating specific workloads such as machine learning, data analytics, and network processing. The programmability of FPGAs allows for customization and adaptation to changing workload requirements.

Frequently Asked Questions (FAQ)

-

Q: Can an FPGA be converted to an ASIC?

A: Yes, it is possible to convert an FPGA design to an ASIC. This process is known as FPGA-to-ASIC conversion or FPGA prototyping. The FPGA design is used as a starting point, and the functionality is then implemented using ASIC technology. This approach allows for faster time-to-market and lower risk compared to starting with a direct ASIC design. -

Q: Are FPGAs cheaper than ASICs?

A: The cost comparison between FPGAs and ASICs depends on the production volume. For low to medium volume production, FPGAs are generally cheaper due to their lower upfront costs and faster development cycle. However, for high-volume production, ASICs become more cost-effective in the long run due to their lower per-unit cost. -

Q: Can FPGAs be used for high-performance computing?

A: Yes, FPGAs are increasingly being used for high-performance computing applications. They offer the ability to parallelize and accelerate specific algorithms and workloads. FPGAs are particularly well-suited for applications that require low latency, high bandwidth, and custom processing pipelines. -

Q: Are ASICs more secure than FPGAs?

A: ASICs can offer higher security compared to FPGAs due to their fixed functionality and the difficulty in reverse-engineering the custom design. FPGAs, being programmable, may be more vulnerable to tampering and reverse-engineering attempts. However, modern FPGAs often include security features such as bitstream encryption and authentication to enhance their security. -

Q: Can FPGAs be used for artificial intelligence (AI) applications?

A: Yes, FPGAs are being used for AI applications, particularly in the field of deep learning. FPGAs offer the ability to parallelize and accelerate the computation-intensive operations involved in neural networks. They provide flexibility in terms of customizing the architecture for specific AI workloads and can offer lower latency and higher performance compared to general-purpose processors.

Conclusion

In summary, FPGAs and ASICs are two distinct options for implementing digital circuits, each with its own advantages and limitations. FPGAs offer flexibility, rapid prototyping, and lower upfront costs, making them suitable for applications that require frequent design changes and low to medium volume production. ASICs, on the other hand, provide higher performance, lower power consumption, and cost-effectiveness for high-volume production, but have higher upfront costs and longer development cycles.

When choosing between an FPGA and an ASIC, consider factors such as design flexibility, performance requirements, power consumption, production volume, time-to-market, and budget. Understanding the key differences between FPGAs and ASICs will help you make an informed decision based on your specific project requirements.

As technology advances, the boundaries between FPGAs and ASICs continue to blur, with the emergence of hybrid solutions such as programmable SoCs and FPGA-to-ASIC conversion. These advancements provide designers with more options to balance flexibility, performance, and cost in their digital circuit implementations.

Ultimately, the choice between an FPGA and an ASIC depends on the unique needs of your project. By carefully evaluating your requirements and considering the trade-offs between flexibility, performance, cost, and time-to-market, you can select the most suitable solution for your application.

Leave a Reply