Introduction to PCB Cutting

Printed Circuit Boards (PCBs) are essential components in modern electronics. They provide a platform for mounting and connecting various electronic components, enabling the creation of complex circuits. One crucial aspect of PCB fabrication is cutting the board to the desired shape and size. In this article, we will explore the best methods for PCB cutting, including techniques, tools, and best practices.

Why Precise PCB Cutting Matters

Accurate PCB cutting is crucial for several reasons:

-

Functionality: Precise cutting ensures that the PCB fits properly into its designated enclosure or device, allowing for optimal functionality and performance.

-

Aesthetics: Clean and accurate cuts contribute to the overall appearance and professionalism of the final product.

-

Reliability: Properly cut PCBs are less likely to experience mechanical stress or damage, enhancing the reliability of the electronic device.

PCB Cutting Techniques

There are several techniques used for cutting PCBs, each with its own advantages and limitations. Let’s explore some of the most common methods:

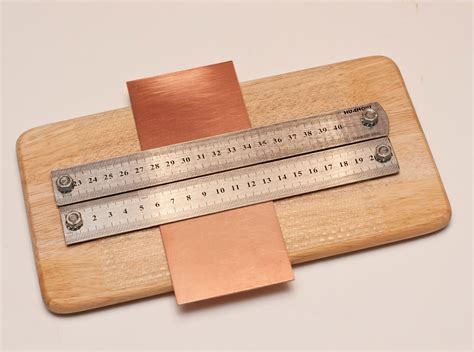

Manual Cutting

Manual PCB cutting involves using hand tools like saws, cutters, or shears to cut the board. This method is suitable for low-volume production or prototyping. However, it requires skill and precision to achieve accurate cuts and can be time-consuming.

Tools used for manual PCB cutting include:

- Hacksaw

- Jeweler’s saw

- Nibbling tool

- Shears

Mechanical Cutting

Mechanical cutting employs machines to automate the PCB cutting process. These machines offer higher accuracy, consistency, and speed compared to manual methods. Some common mechanical cutting techniques include:

Punching

Punching uses a die and a punch to create holes or cut out specific shapes in the PCB. It is suitable for high-volume production and can achieve precise cuts. However, it requires the creation of custom dies for each unique shape.

Routing

Routing involves using a computer-controlled router to cut the PCB along a predefined path. It offers flexibility in terms of shape and size and is suitable for both prototyping and production. CNC (Computer Numerical Control) routers are commonly used for this purpose.

V-Scoring

V-scoring uses a specialized blade to create a V-shaped groove on the PCB. This weakens the board along the scored line, allowing it to be easily snapped apart. V-scoring is often used for creating breakaway tabs or separating multiple PCBs from a panel.

Laser Cutting

Laser cutting employs a high-powered laser beam to cut through the PCB material. It offers several advantages:

- High precision and accuracy

- Minimal material wastage

- No physical contact with the board

- Ability to create intricate shapes and designs

Laser cutting is suitable for both prototyping and production, especially when dealing with complex geometries or sensitive materials.

Best Practices for PCB Cutting

To ensure optimal results when cutting PCBs, consider the following best practices:

-

Choose the appropriate cutting method: Select the cutting technique based on factors like production volume, required accuracy, board material, and available resources.

-

Use proper tools and equipment: Invest in high-quality tools and machines suitable for your chosen cutting method. Regularly maintain and calibrate them for consistent performance.

-

Follow design guidelines: Adhere to the recommended design guidelines for your chosen cutting method. Consider factors like minimum cut widths, clearances, and tolerances.

-

Implement safety measures: Ensure a safe working environment by wearing protective gear, following proper handling procedures, and disposing of waste materials responsibly.

-

Perform quality checks: Regularly inspect the cut PCBs for accuracy, cleanness, and any signs of damage. Implement quality control measures to maintain consistent results.

PCB Cutting Equipment

Investing in the right equipment is crucial for efficient and accurate PCB cutting. Here are some essential tools and machines for each cutting method:

| Cutting Method | Equipment |

|---|---|

| Manual | – Hacksaw – Jeweler’s saw – Nibbling tool – Shears |

| Mechanical | – Punching machine – CNC router – V-scoring machine |

| Laser | – Laser cutting machine |

When selecting equipment, consider factors like precision, speed, ease of use, and compatibility with your PCB materials and production requirements.

Frequently Asked Questions (FAQ)

-

What is the most accurate method for cutting PCBs?

Laser cutting and CNC routing offer the highest accuracy and precision among PCB cutting methods. They provide consistent results and can handle complex shapes and designs. -

Can I cut PCBs using a regular saw?

While it is possible to cut PCBs using a regular saw, it is not recommended for precise cuts. Manual cutting with hand tools requires skill and patience to achieve acceptable results. For better accuracy and efficiency, consider using specialized equipment like CNC routers or laser cutters. -

How do I choose the right PCB cutting method for my project?

When selecting a PCB cutting method, consider factors such as production volume, required accuracy, board material, and available resources. Manual cutting is suitable for low-volume prototyping, while mechanical and laser cutting methods are better suited for high-volume production and precise cuts. -

What safety precautions should I take when cutting PCBs?

Always wear protective gear like safety glasses and gloves when cutting PCBs. Ensure proper ventilation to avoid inhaling dust or fumes. Follow the manufacturer’s guidelines for operating cutting equipment safely. Dispose of waste materials, such as cut PCB pieces and dust, responsibly. -

How can I ensure consistent and accurate PCB cuts?

To achieve consistent and accurate PCB cuts, invest in high-quality cutting equipment and regularly maintain and calibrate it. Follow the recommended design guidelines for your chosen cutting method, such as minimum cut widths and clearances. Implement quality control measures and perform regular inspections to identify and address any issues promptly.

Conclusion

Cutting PCBs accurately is a critical step in the PCB fabrication process. By understanding the various cutting techniques, tools, and best practices, you can ensure precise and reliable results. Whether you choose manual, mechanical, or laser cutting methods, investing in the right equipment and following proper guidelines will help you achieve clean and accurate PCB cuts.

Remember to prioritize safety, maintain your equipment, and perform regular quality checks to ensure consistent results. With the right approach and tools, you can efficiently cut PCBs and create high-quality electronic devices.

Leave a Reply