What is BGA Rework?

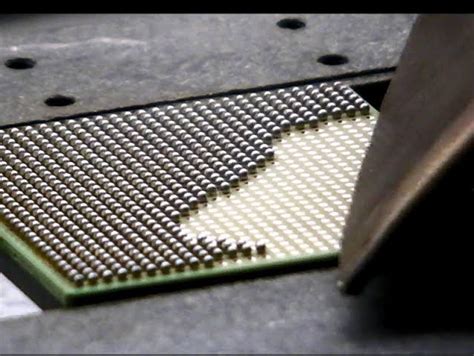

BGA (Ball Grid Array) rework is the process of repairing or replacing BGA components on printed circuit boards (PCBs). BGA components are integrated circuits that use an array of solder balls on the bottom for connection to the PCB. These components are widely used in electronic devices due to their compact size and high pin count.

However, BGA components can be challenging to work with due to their small size and the difficulty in accessing the solder balls beneath the component. BGA rework requires specialized equipment and expertise to ensure proper removal, replacement, and alignment of the component.

Common Reasons for BGA Rework

There are several reasons why BGA rework may be necessary:

- Manufacturing defects: Issues during the manufacturing process, such as improper soldering or component placement, may require rework.

- Component failure: BGA components may fail due to various reasons, such as overheating, physical damage, or aging, necessitating replacement.

- Design changes: Changes in the PCB design may require the removal and replacement of BGA components.

- Counterfeit component detection: Suspected counterfeit BGA components may need to be removed and replaced with genuine parts.

BGA Rework Process

The BGA rework process typically involves the following steps:

- Pre-rework analysis: The PCB is inspected to identify the BGA component requiring rework and to assess the overall condition of the board.

- Component removal: The faulty BGA component is removed using specialized equipment, such as a hot air rework station or infrared heating system. Care must be taken to avoid damaging the PCB or neighboring components.

- Site preparation: The PCB pads are cleaned and prepared for the new component. This may involve removing excess solder, applying flux, and inspecting for any damage.

- Component placement: The new BGA component is aligned and placed on the prepared site using a pick-and-place machine or manual placement tool.

- Reflow soldering: The PCB is heated to melt the solder balls and create a connection between the component and the board. This is typically done using a reflow oven or hot air rework station.

- Inspection and testing: The reworked PCB is inspected for proper component alignment and solder joint quality. Functional testing may also be performed to ensure the device operates as intended.

Equipment Used in BGA Rework

BGA rework requires specialized equipment to ensure precise and reliable results. Some of the key equipment used in the process includes:

| Equipment | Description |

|---|---|

| Hot air rework station | Uses heated air to remove and solder BGA components |

| Infrared heating system | Employs infrared radiation to heat and remove BGA components |

| Reflow oven | Heats the entire PCB to melt solder and create connections |

| Pick-and-place machine | Automatically places BGA components on the PCB with high precision |

| Microscopes and magnifiers | Used for visual inspection and alignment of components |

| Soldering iron and tips | For manual soldering and touch-up work |

Challenges in BGA Rework

BGA rework presents several challenges that must be addressed to ensure successful outcomes:

- Thermal management: Controlling the temperature during component removal and soldering is crucial to avoid damaging the PCB or components.

- Component alignment: Precise alignment of the BGA component on the PCB pads is essential for proper connections and functionality.

- Solder joint quality: Ensuring the formation of reliable solder joints between the component and PCB is critical for long-term performance.

- Handling and storage: BGA components are sensitive to moisture and static electricity, requiring proper handling and storage procedures.

Thermal Management Techniques

To address thermal management challenges, BGA rework companies employ various techniques, such as:

- Localized heating: Using hot air or infrared heating systems to focus heat on the specific BGA component, minimizing the risk of damage to nearby components.

- Temperature profiling: Developing and following precise temperature profiles for component removal and soldering to ensure optimal results.

- Thermal shielding: Employing heat shields or barriers to protect sensitive components from excessive heat during the rework process.

Component Alignment Methods

Accurate component alignment is critical for successful BGA rework. Some common alignment methods include:

- Vision systems: Using camera-based systems to align the BGA component with the PCB pads.

- Split-beam optics: Employing a split-beam optical system to superimpose the image of the component onto the PCB for alignment.

- Fiducial markers: Using reference marks on the PCB and component to guide alignment.

Choosing a BGA Rework Company

When selecting a BGA rework company, consider the following factors:

- Experience and expertise: Look for a company with a proven track record in BGA rework and experience with your specific components and PCB types.

- Equipment and facilities: Ensure the company has the necessary equipment and facilities to handle your BGA rework needs, including advanced rework stations, reflow ovens, and inspection tools.

- Quality control and certifications: Choose a company with stringent quality control processes and relevant certifications, such as IPC-7711/7721, to ensure reliable and consistent results.

- Turnaround time and pricing: Consider the company’s turnaround time and pricing structure to ensure they align with your project requirements and budget.

Top BGA Rework Companies

Here are some of the leading BGA rework companies known for their expertise and quality of service:

| Company | Location | Services |

|---|---|---|

| Circuit Technology Center | Haverhill, MA, USA | BGA rework, PCB Repair, component obsolescence solutions |

| Rochester Electronics | Newburyport, MA, USA | BGA rework, component sourcing, testing, and inspection |

| Acculogic | Markham, ON, Canada | BGA rework, PCB repair, testing, and engineering services |

| Renex | Prague, Czech Republic | BGA rework, PCB repair, component sourcing, and testing |

| iFixit | San Luis Obispo, CA, USA | BGA rework, device repair, and online repair guides |

Case Studies

Case Study 1: Smartphone Manufacturer

A leading smartphone manufacturer encountered a high failure rate in one of their models due to a faulty BGA component. They partnered with a BGA rework company to address the issue. The rework company developed a customized rework process, utilizing advanced hot air rework stations and vision systems for precise component alignment. The successful rework resulted in a significant reduction in failure rates and improved overall device reliability.

Case Study 2: Aerospace Electronics

An aerospace electronics company required BGA rework services for a mission-critical PCB used in satellite communication systems. The BGA rework company collaborated with the client’s engineering team to develop a rework procedure that met the stringent quality and reliability requirements of the aerospace industry. The reworked PCBs passed rigorous testing and were successfully deployed in the client’s satellite systems.

Frequently Asked Questions (FAQ)

-

Q: How long does BGA rework typically take?

A: The duration of BGA rework depends on various factors, such as the complexity of the PCB, the number of components requiring rework, and the rework company’s workload. Simple rework jobs may be completed within a day, while more complex projects can take several days or weeks. -

Q: Can all BGA components be reworked?

A: Most BGA components can be reworked, provided the PCB and component are not severely damaged. However, some ultra-fine pitch BGA components or those with unique packaging may require specialized equipment and expertise. -

Q: Is BGA rework cost-effective compared to PCB replacement?

A: In many cases, BGA rework is more cost-effective than replacing the entire PCB, especially for high-value or custom-designed boards. However, the cost-effectiveness depends on the extent of the damage and the complexity of the rework process. -

Q: Can BGA rework be performed on RoHS-compliant PCBs?

A: Yes, BGA rework can be performed on RoHS-compliant PCBs using lead-free solder and compatible rework equipment. Rework companies experienced in handling RoHS-compliant boards should be chosen to ensure proper procedures are followed. -

Q: What is the success rate of BGA rework?

A: The success rate of BGA rework depends on various factors, such as the skill of the technicians, the quality of the equipment, and the condition of the PCB and components. Reputable BGA rework companies typically have success rates exceeding 90% for most rework projects.

Conclusion

BGA rework is a critical process for repairing and maintaining electronic devices that utilize BGA components. The complexity and precision required in BGA rework necessitate the use of specialized equipment and expertise. When selecting a BGA rework company, it is essential to consider factors such as experience, equipment, quality control, and turnaround time to ensure successful outcomes.

As electronic devices continue to evolve and become more complex, the demand for reliable BGA rework services will only increase. By partnering with experienced and reputable BGA rework companies, manufacturers can effectively address component failures, design changes, and other issues, ultimately leading to improved product quality and customer satisfaction.

Leave a Reply