What is a Drill File?

A drill file, also known as a NC drill file or PCB drill file, is a computer-generated file that contains information about the location, size, and type of holes to be drilled in a printed circuit board (PCB) during the manufacturing process. The file is created using computer-aided design (CAD) software and is used to control the drilling machines that create the holes in the PCB.

The drill file is an essential part of the PCB manufacturing process as it ensures that the holes are drilled accurately and consistently. The file contains a list of drill coordinates and sizes, which the drilling machine uses to create the holes in the correct locations and sizes.

Why is a Drill File Important?

A drill file is important because it ensures that the holes in a PCB are drilled accurately and consistently. If the holes are not drilled correctly, it can lead to a variety of problems, such as:

- Poor electrical connections

- Shorts or open circuits

- Mechanical stress on components

- Difficulty in assembling the PCB

By using a drill file, PCB Manufacturers can ensure that the holes are drilled correctly, which helps to prevent these problems and ensures that the PCB functions as intended.

Drill File Formats

There are several different formats for drill files, each with its own advantages and disadvantages. Some of the most common formats include:

Excellon Format

The Excellon format is one of the most widely used formats for drill files. It was developed by the Excellon Corporation and has become a standard in the PCB industry. The Excellon format uses a text-based format that is easy to read and edit, making it a popular choice for many PCB designers and manufacturers.

Sieb & Meyer Format

The Sieb & Meyer format is another common format for drill files. It is similar to the Excellon format but uses a slightly different syntax. The Sieb & Meyer format is often used by European PCB manufacturers.

Gerber Format

The Gerber format is a vector-based format that is commonly used for PCB Artwork files. While it is not specifically designed for drill files, it can be used to generate drill files by including the necessary drill information in the file.

ODB++ Format

The ODB++ format is a newer format that was developed by Valor Computerized Systems. It is a comprehensive format that includes not only drill information but also other PCB manufacturing data such as component placement and routing information.

Creating a Drill File

Creating a drill file involves several steps, which are typically performed using CAD software. The basic steps are as follows:

-

Design the PCB: The first step in creating a drill file is to design the PCB using CAD software. This involves creating a schematic diagram of the circuit and then laying out the components and traces on the PCB.

-

Define the drill holes: Once the PCB design is complete, the next step is to define the drill holes. This involves specifying the location, size, and type of each hole that needs to be drilled in the PCB.

-

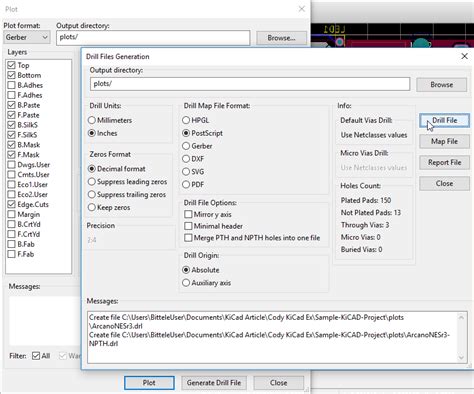

Generate the drill file: After the drill holes have been defined, the next step is to generate the drill file. This is typically done using a separate tool within the CAD software that converts the drill hole information into a format that can be used by the drilling machine.

-

Verify the drill file: Before sending the drill file to the PCB manufacturer, it is important to verify that the file is correct. This involves checking the file for errors and ensuring that the drill holes are in the correct locations and sizes.

-

Send the drill file to the manufacturer: Once the drill file has been verified, it can be sent to the PCB manufacturer along with the other necessary files, such as the Gerber files for the PCB artwork.

Common Drill File Errors

While creating a drill file is a straightforward process, there are several common errors that can occur. Some of the most common errors include:

Incorrect Drill Sizes

One of the most common errors in drill files is incorrect drill sizes. This can occur if the wrong size is specified in the CAD software or if the drilling machine is not calibrated correctly. Using the wrong drill size can lead to holes that are too small or too large, which can cause problems with component placement and soldering.

Missing Drill Holes

Another common error is missing drill holes. This can occur if the holes are not defined in the CAD software or if they are accidentally deleted during the file generation process. Missing drill holes can prevent components from being properly mounted on the PCB and can cause short circuits or other problems.

Overlapping Drill Holes

Overlapping drill holes can occur if the holes are placed too close together or if the wrong size drill bit is used. This can weaken the PCB and cause problems with component placement and soldering.

Incorrect Drill Coordinates

Incorrect drill coordinates can occur if the wrong units are used or if the origin point is not set correctly in the CAD software. This can cause the holes to be drilled in the wrong locations, which can lead to a variety of problems, including component misalignment and short circuits.

Best Practices for Drill File Generation

To ensure that drill files are generated correctly and without errors, there are several best practices that should be followed:

Use a Standard Format

Using a standard format for drill files, such as Excellon or Gerber, can help to ensure that the file is compatible with the PCB manufacturer’s equipment and software.

Use Consistent Units

It is important to use consistent units throughout the drill file and to specify the units in the file header. This helps to ensure that the drilling machine interprets the file correctly.

Set the Origin Point

Setting the origin point correctly in the CAD software is essential for ensuring that the drill holes are placed in the correct locations on the PCB.

Use Appropriate Drill Sizes

Using appropriate drill sizes is important for ensuring that components can be properly mounted on the PCB and that there are no short circuits or other problems.

Verify the Drill File

Verifying the drill file before sending it to the manufacturer is essential for catching any errors or problems before the PCB is manufactured.

Drill File Generation Tools

There are many different tools available for generating drill files, ranging from simple standalone tools to complex CAD software packages. Some of the most popular tools include:

Eagle CAD

Eagle CAD is a popular PCB design software package that includes tools for generating drill files. It supports a variety of drill file formats, including Excellon and Sieb & Meyer.

KiCad

KiCad is a free and open-source PCB design software package that includes tools for generating drill files. It supports the Excellon format and includes a variety of other PCB design tools.

Altium Designer

Altium Designer is a high-end PCB design software package that includes advanced tools for generating drill files. It supports the Excellon and Gerber formats, as well as ODB++.

Mentor Graphics PADS

Mentor Graphics PADS is another popular PCB design software package that includes tools for generating drill files. It supports the Excellon format and includes a variety of other PCB design tools.

Conclusion

Generating accurate and error-free drill files is essential for ensuring that PCBs are manufactured correctly and function as intended. By following best practices and using appropriate tools, PCB designers and manufacturers can create drill files that meet their needs and ensure the highest quality PCBs.

Frequently Asked Questions

-

What is the most common drill file format?

The most common drill file format is Excellon, which is widely used in the PCB industry. -

Can drill files be generated using any CAD software?

Most PCB design CAD software packages include tools for generating drill files, but some may be more limited in their capabilities than others. -

What should I do if I find an error in my drill file?

If you find an error in your drill file, you should correct it as soon as possible and regenerate the file. It is important to catch errors before sending the file to the manufacturer to avoid costly mistakes. -

How do I know what drill sizes to use?

The appropriate drill sizes to use will depend on the components being used and the requirements of the PCB. Consult with the component manufacturers and the PCB manufacturer to determine the appropriate drill sizes. -

Can I use different units in my drill file?

It is important to use consistent units throughout the drill file and to specify the units in the file header. Mixing units can cause errors and problems with the drilling process.

| Drill File Format | Advantages | Disadvantages |

|---|---|---|

| Excellon | – Widely used and supported – Easy to read and edit |

– Limited to drill information only |

| Sieb & Meyer | – Similar to Excellon – Often used by European manufacturers |

– Less widely used than Excellon |

| Gerber | – Can include drill information in addition to other PCB data | – Not specifically designed for drill files |

| ODB++ | – Comprehensive format that includes drill data and other PCB information | – Newer format that may not be supported by all manufacturers yet |

Leave a Reply