What is Insufficient Solder?

Insufficient solder refers to a situation where there is not enough solder applied to create a proper connection between the electronic components. This can result in a weak or incomplete bond, which can cause electrical issues, reduced performance, or even complete failure of the electronic device.

Symptoms of Insufficient Solder

Some common symptoms of insufficient solder include:

- Poor electrical continuity

- Intermittent connections

- Increased resistance in the circuit

- Visual gaps or voids in the solder joint

Causes of Insufficient Solder

There are several reasons why insufficient solder may occur during the soldering process:

Inadequate Solder Amount

One of the most common causes of insufficient solder is simply not applying enough solder to the joint. This can happen if the operator is inexperienced or rushing through the process, or if the solder wire is too thin for the application.

Incorrect Soldering Temperature

If the soldering iron temperature is too low, the solder may not melt properly, resulting in insufficient solder flow. On the other hand, if the temperature is too high, the solder may evaporate or burn off before it can properly bond with the components.

Contaminated or Oxidized Surfaces

Dirt, grease, or oxidation on the surfaces of the components or the soldering iron tip can prevent the solder from properly adhering. This can lead to insufficient solder and a weak connection.

Improper Soldering Technique

Poor soldering technique, such as not applying the soldering iron for long enough or not properly positioning the components, can result in insufficient solder. It is important to follow proper soldering procedures to ensure a strong and reliable connection.

Preventing Insufficient Solder

To prevent insufficient solder, consider the following tips:

-

Use the appropriate amount of solder for the job. A general rule of thumb is to use a solder diameter that is approximately the same as the lead diameter of the component.

-

Ensure that the soldering iron temperature is set correctly for the type of solder being used. Consult the solder manufacturer’s guidelines for the recommended temperature range.

-

Clean the surfaces of the components and the soldering iron tip before soldering. Use a soldering iron tip cleaner or a damp sponge to remove any contamination or oxidation.

-

Follow proper soldering techniques, such as heating the joint sufficiently, applying the solder to the joint (not the iron), and allowing the solder to flow around the connection.

-

Use flux to help the solder flow and adhere to the surfaces. Flux removes oxides and contamination, promoting better solder wetting.

Fixing Insufficient Solder

If you have already soldered a joint and discover that there is insufficient solder, you can take the following steps to fix the issue:

-

Re-melt the existing solder: Apply the soldering iron to the joint and allow the existing solder to melt. This will help the solder to flow and redistribute around the connection.

-

Add more solder: If re-melting the existing solder is not enough, add a small amount of fresh solder to the joint. Be careful not to apply too much, as this can lead to excessive solder and create a different set of problems.

-

Use a solder wick: If there is excess solder on the joint, you can use a desoldering wick (also known as solder braid) to remove it. Place the wick on the joint and apply the soldering iron to the wick. The excess solder will be absorbed into the wick, leaving a clean joint ready for re-soldering.

-

Clean the joint: After fixing the insufficient solder, clean the joint with isopropyl alcohol to remove any flux residue.

Insufficient Solder in Different Applications

Insufficient solder can occur in various electronic applications, each with its own specific challenges and considerations.

Through-Hole Components

Through-hole components are inserted into holes drilled in a printed circuit board (PCB) and soldered on the opposite side. Insufficient solder in through-hole joints can lead to loose components and poor electrical connections. To ensure sufficient solder in through-hole joints:

- Use a soldering iron with a tip size appropriate for the component lead diameter

- Apply solder to both the component lead and the PCB pad

- Ensure the solder flows through the hole and forms a concave fillet on both sides of the joint

Surface Mount Components

Surface mount components are soldered directly onto the surface of a PCB. Insufficient solder in surface mount joints can cause components to lift off the board or create open circuits. To prevent insufficient solder in surface mount applications:

- Use solder paste applied through a stencil for precise Solder volume control

- Ensure proper component placement and alignment before soldering

- Use a reflow oven with a well-controlled temperature profile to melt the solder evenly

Wires and Cables

Soldering wires and cables requires creating a strong mechanical and electrical connection. Insufficient solder in wire joints can result in weak or intermittent connections. To achieve sufficient solder in wire and cable joints:

- Strip the wire insulation carefully to avoid damaging the conductor strands

- Tin the wire strands and the terminal or connector before soldering

- Apply enough solder to create a solid joint without excessive buildup

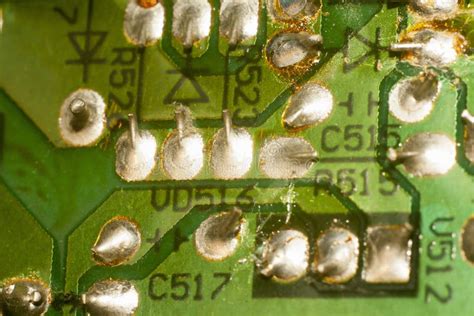

Inspecting for Insufficient Solder

Visual inspection is the first line of defense against insufficient solder. Here are some methods for inspecting solder joints:

Visual Inspection

- Look for visible gaps or voids in the solder joint

- Check for a concave fillet shape, indicating proper solder flow

- Verify that the solder joint covers the entire component lead or pad

Magnification

- Use a magnifying lens or microscope to examine solder joints in detail

- Look for small voids, cracks, or incomplete solder coverage

X-Ray Inspection

- X-ray inspection can reveal hidden defects in solder joints, such as voids or insufficient solder under components

- This method is particularly useful for inspecting ball grid array (BGA) and other high-density packages

Solder Joint Reliability

Insufficient solder can have a significant impact on the reliability of solder joints over time. Weak or incomplete solder joints are more susceptible to failure due to mechanical stress, thermal cycling, or vibration. To ensure long-term reliability of solder joints:

- Follow proper soldering techniques and use the appropriate amount of solder

- Use high-quality solder alloys with the correct composition for the application

- Implement a robust quality control process, including visual inspection and testing

- Consider using conformal coating or potting to protect solder joints from environmental stresses

Frequently Asked Questions (FAQ)

-

Q: Can insufficient solder cause a complete failure of an electronic device?

A: Yes, insufficient solder can lead to a complete failure of an electronic device if it results in an open circuit or a critical component becoming disconnected. -

Q: How much solder should I use for a typical through-hole joint?

A: A general guideline is to use a solder volume that results in a concave fillet on both sides of the joint, with the solder covering the entire component lead and pad. The exact amount will depend on the size of the component and the hole diameter. -

Q: Can I use a soldering gun instead of a soldering iron for fixing insufficient solder?

A: While a soldering gun can be used for some soldering tasks, it is generally not recommended for fixing insufficient solder. Soldering guns tend to have higher power output and can deliver too much heat, potentially damaging components or the PCB. A soldering iron with adjustable temperature control is a better choice for most soldering applications. -

Q: What is the best way to remove excess solder when fixing an insufficient solder joint?

A: The best way to remove excess solder is to use a desoldering wick (also known as solder braid). Place the wick on the joint and apply the soldering iron to the wick. The excess solder will be absorbed into the wick, leaving a clean joint ready for re-soldering. Alternatively, you can use a desoldering pump (solder sucker) to remove excess solder. -

Q: Can insufficient solder cause intermittent problems that are difficult to diagnose?

A: Yes, insufficient solder can cause intermittent problems that may be difficult to diagnose. A weak or incomplete solder joint may work initially but can fail intermittently due to thermal expansion, vibration, or mechanical stress. These intermittent failures can be challenging to troubleshoot, as the problem may not be apparent during visual inspection or initial testing. In such cases, using advanced inspection techniques like X-ray imaging or performing stress tests can help identify the root cause of the issue.

Conclusion

Insufficient solder is a common issue in electronic assembly that can lead to poor electrical connections, reduced performance, and device failure. Understanding the causes, prevention methods, and techniques for fixing insufficient solder is essential for anyone involved in soldering or electronics manufacturing.

By following proper soldering techniques, using the appropriate tools and materials, and implementing a robust quality control process, you can minimize the occurrence of insufficient solder and ensure the reliability of your electronic devices.

Remember, a well-executed solder joint is critical for the long-term performance and reliability of electronic systems. Taking the time to address insufficient solder issues can save time, money, and frustration in the long run.

Leave a Reply