Introduction to Audio Amplification

Audio amplification is the process of increasing the power of an audio signal to drive speakers or headphones. It is a crucial component in any audio system, whether it’s a home theater, car stereo, or portable music player. The LM1875 is a popular choice for audio amplification due to its high performance, low distortion, and ease of use.

What is the LM1875?

The LM1875 is a monolithic power amplifier IC designed for audio applications. It is capable of delivering up to 30 watts of power into an 8-ohm load with a minimum of external components. The LM1875 features a wide supply voltage range, low distortion, and excellent temperature stability.

| Parameter | Value |

|---|---|

| Output Power (8Ω) | 30W |

| Supply Voltage Range | ±10V to ±30V |

| Total Harmonic Distortion (THD) | 0.015% (typical) |

| Input Sensitivity | 0.75V (for 30W output) |

| Slew Rate | 9V/μs |

Advantages of the LM1875

- High output power: The LM1875 can deliver up to 30W into an 8Ω load, making it suitable for a wide range of audio applications.

- Low distortion: With a typical THD of 0.015%, the LM1875 provides clean and accurate audio reproduction.

- Wide supply voltage range: The LM1875 can operate with supply voltages ranging from ±10V to ±30V, allowing flexibility in power supply design.

- Excellent temperature stability: The LM1875 maintains its performance over a wide temperature range, ensuring reliable operation in various environments.

- Ease of use: The LM1875 requires minimal external components, simplifying circuit design and reducing overall system cost.

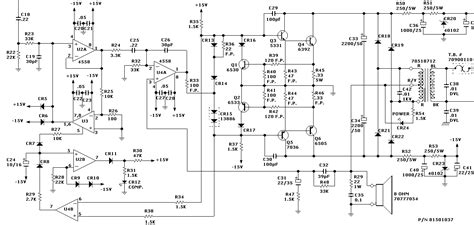

Basic Circuit Design

Power Supply Considerations

The LM1875 requires a dual-voltage power supply for proper operation. The supply voltages should be within the range of ±10V to ±30V. It is essential to use a well-regulated and low-noise power supply to ensure optimal performance.

A typical power supply circuit for the LM1875 includes the following components:

– Transformer: A center-tapped transformer with a secondary voltage rating suitable for the desired supply voltages.

– Bridge rectifier: A full-wave bridge rectifier to convert the AC voltage from the transformer to DC.

– Filter capacitors: Large-value electrolytic capacitors to smooth the rectified DC voltage and reduce ripple.

– Voltage regulators (optional): Linear voltage regulators, such as the LM7815 and LM7915, can be used to provide stable and low-noise supply voltages.

Input Stage

The input stage of the LM1875 circuit consists of the following components:

– Input coupling capacitor: A non-polarized capacitor (typically 1μF to 10μF) to block any DC voltage from the input signal.

– Input resistor: A resistor (typically 10kΩ to 100kΩ) to provide a proper input impedance and limit the input current.

– Potentiometer (optional): A logarithmic potentiometer can be used as a volume control by varying the input signal level.

Output Stage

The output stage of the LM1875 circuit includes the following components:

– Output coupling capacitor: A large-value non-polarized capacitor (typically 1000μF to 4700μF) to block DC voltage from reaching the speakers.

– Zobel network: A series RC network (typically 10Ω and 0.1μF) connected in parallel with the speaker to improve stability and reduce high-frequency oscillations.

– Speaker: An 8Ω speaker or a combination of speakers with a total impedance of 8Ω.

Advanced Circuit Techniques

Parallel Operation

For higher output power requirements, multiple LM1875 ICs can be connected in parallel. When connecting LM1875s in parallel, it is important to ensure proper current sharing and thermal management.

To achieve equal current sharing, resistors (typically 0.1Ω to 0.22Ω) should be added in series with the outputs of each LM1875. These resistors help to balance the output currents and prevent one IC from carrying a disproportionate share of the load.

Proper thermal management is crucial when operating LM1875s in parallel. Each IC should be mounted on a suitable heatsink to dissipate the generated heat effectively. The heatsinks should be chosen based on the total power dissipation and the ambient temperature.

Bridge Mode Operation

The LM1875 can also be configured in bridge mode to achieve higher output power. In bridge mode, two LM1875s are connected in a push-pull configuration, allowing them to drive the load with opposite polarity signals.

To set up the LM1875 in bridge mode:

1. Connect the non-inverting input of the first LM1875 to the input signal.

2. Connect the inverting input of the first LM1875 to ground.

3. Connect the non-inverting input of the second LM1875 to ground.

4. Connect the inverting input of the second LM1875 to the output of the first LM1875.

5. Connect the speaker between the outputs of the two LM1875s.

In bridge mode, the output power is quadrupled compared to a single LM1875 operating in standard mode. However, the minimum load impedance is also doubled to 16Ω.

Thermal Management

Proper thermal management is essential for the reliable operation and longevity of the LM1875. The IC generates heat during operation, which must be dissipated to prevent overheating and damage.

The LM1875 has a built-in thermal shutdown protection feature that activates when the junction temperature exceeds 150°C. However, it is recommended to keep the junction temperature well below this limit for optimal performance and reliability.

To ensure proper thermal management:

1. Use a suitable heatsink: Select a heatsink with sufficient thermal resistance to maintain the junction temperature within safe limits. The required thermal resistance can be calculated based on the power dissipation and ambient temperature.

2. Apply thermal compound: Use a high-quality thermal compound between the LM1875 and the heatsink to ensure efficient heat transfer.

3. Provide adequate ventilation: Ensure that there is sufficient airflow around the heatsink to facilitate heat dissipation.

4. Monitor temperature: Use a temperature sensor (e.g., a thermistor) to monitor the heatsink temperature and implement a thermal protection circuit if necessary.

PCB Layout Considerations

Proper PCB layout is crucial for achieving optimal performance and minimizing noise and interference in LM1875-based audio amplifier circuits. Here are some key considerations:

-

Power supply decoupling: Place decoupling capacitors close to the LM1875’s power supply pins to minimize supply noise and ensure stable operation. Use a combination of ceramic and electrolytic capacitors for effective decoupling across a wide frequency range.

-

Ground plane: Use a solid ground plane on the PCB to provide a low-impedance return path for the audio signals. Connect all ground points to the ground plane using short and direct traces.

-

Signal routing: Route the input and output audio signals away from power supply traces and other high-current paths to minimize crosstalk and interference. Use short and direct traces for the audio signals to minimize parasitic capacitance and inductance.

-

Input and output separation: Physically separate the input and output sections of the PCB to reduce the risk of feedback and oscillations. Use separate ground planes for the input and output stages, connected at a single point (star ground) near the power supply.

-

Heatsink mounting: Provide adequate space for mounting the heatsink and ensure proper thermal contact between the LM1875 and the heatsink. Use thermal vias to transfer heat from the PCB to the heatsink if necessary.

-

Component placement: Place the components in a logical and organized manner to minimize trace lengths and improve signal integrity. Keep the input and output coupling capacitors close to the LM1875 pins.

-

EMI reduction: Implement EMI reduction techniques, such as using shielded cables for input and output connections, adding ferrite beads on power supply leads, and using a grounded metal enclosure to shield the circuit from external interference.

Frequently Asked Questions (FAQ)

1. What is the maximum output power of the LM1875?

The LM1875 can deliver up to 30 watts of continuous average power into an 8-ohm load with a minimum of external components.

2. Can the LM1875 be used with a single-voltage power supply?

No, the LM1875 requires a dual-voltage power supply for proper operation. The supply voltages should be within the range of ±10V to ±30V.

3. What is the minimum load impedance for the LM1875?

The minimum recommended load impedance for the LM1875 is 4 ohms. However, for optimal performance and reliability, it is advisable to use loads with an impedance of 8 ohms or higher.

4. How can I reduce the noise in my LM1875-based audio amplifier?

To reduce noise in your LM1875-based audio amplifier, ensure proper power supply decoupling, use a solid ground plane, separate the input and output sections of the PCB, and implement EMI reduction techniques. Additionally, use high-quality, low-noise components and keep the PCB layout clean and organized.

5. Can I use the LM1875 for bridged operation?

Yes, the LM1875 can be configured in bridge mode to achieve higher output power. In bridge mode, two LM1875s are connected in a push-pull configuration, allowing them to drive the load with opposite polarity signals. This configuration quadruples the output power compared to a single LM1875 operating in standard mode.

Conclusion

The LM1875 is a versatile and high-performance audio amplifier IC that offers excellent sound quality, low distortion, and ease of use. By following the guidelines outlined in this comprehensive guide, you can design and build reliable and efficient audio amplifier circuits using the LM1875.

Remember to consider factors such as power supply design, input and output staging, thermal management, and PCB layout when designing your LM1875-based audio amplifier. By paying attention to these crucial aspects, you can achieve optimal performance and enjoy high-quality audio amplification in your projects.

Leave a Reply