Introduction to PCB Design Flow

Printed Circuit Board (PCB) design is a complex process that involves multiple stages and requires careful planning and execution. An optimum PCB design flow ensures that the final product meets the desired specifications, performs reliably, and can be manufactured efficiently. In this article, we will discuss the key steps involved in an optimum PCB design flow and explore best practices for each stage.

The Importance of a Well-Defined PCB Design Flow

A well-defined PCB design flow is crucial for several reasons:

- Consistency: Following a standardized design flow ensures that all team members are on the same page and work towards a common goal.

- Efficiency: A structured design flow minimizes the chances of errors and reduces the time required for iterations and corrections.

- Quality: Adhering to best practices and design guidelines at each stage of the design flow results in a high-quality PCB that meets the required specifications.

- Cost-effectiveness: Optimizing the design flow helps in identifying and resolving issues early in the process, thereby reducing the overall cost of the project.

Stages of an Optimum PCB Design Flow

1. Concept and Feasibility Study

The first stage of the PCB design flow involves defining the project requirements and assessing the feasibility of the design. This stage includes:

- Gathering customer requirements and specifications

- Analyzing the feasibility of the design based on technical and financial constraints

- Creating a high-level block diagram of the system

- Identifying critical components and technologies required for the design

2. Schematic Design

Once the project requirements are defined, the next step is to create a detailed schematic of the PCB. The schematic design stage includes:

- Creating a hierarchical design structure

- Selecting components and creating symbols

- Defining the connectivity between components

- Performing initial design rule checks (DRC) to ensure the schematic is error-free

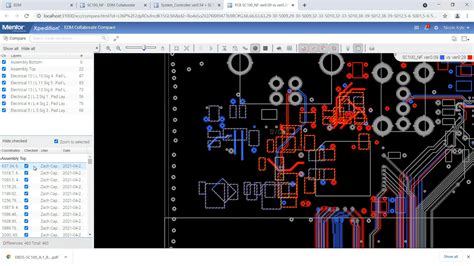

3. Component Placement

After the schematic design is complete, the next stage is to place the components on the PCB layout. The component placement stage involves:

- Defining the board outline and dimensions

- Placing components based on their functional groups and interconnections

- Optimizing the placement for signal integrity, thermal management, and manufacturability

- Performing placement rule checks to ensure the layout meets the design guidelines

4. Routing

The routing stage involves creating the electrical connections between the components on the PCB layout. This stage includes:

- Defining the Layer Stack-Up and routing constraints

- Creating power and ground planes

- Routing the signals based on their net classes and constraints

- Optimizing the routing for signal integrity, EMI/EMC, and manufacturability

- Performing routing rule checks to ensure the layout meets the design guidelines

5. Design Review and Verification

Once the routing is complete, the next stage is to review and verify the design. This stage involves:

- Performing a final design rule check (DRC) to ensure the layout meets all the design constraints

- Running signal integrity simulations to verify the performance of critical signals

- Conducting thermal and power analysis to ensure the PCB can dissipate heat effectively and meet the power requirements

- Collaborating with the manufacturing team to ensure the design is manufacturable and cost-effective

6. Output Generation

The final stage of the PCB design flow involves generating the output files required for manufacturing. This stage includes:

- Generating Gerber Files for each layer of the PCB

- Creating drill files and fabrication drawings

- Generating assembly files, such as pick-and-place and Bill of Materials (BOM)

- Reviewing the output files to ensure they are accurate and complete

Best Practices for an Optimum PCB Design Flow

To ensure an optimum PCB design flow, consider the following best practices:

-

Establish clear design requirements: Clearly define the project requirements and specifications before starting the design process. This helps in avoiding ambiguity and ensures that all stakeholders are aligned.

-

Use a version control system: Implement a version control system to track changes and collaborate effectively with team members. This helps in maintaining a clear history of the design and enables easy rollbacks if needed.

-

Follow design guidelines: Adhere to industry-standard design guidelines and best practices for each stage of the design flow. This ensures that the design is consistent, reliable, and manufacturable.

-

Perform regular design reviews: Conduct regular design reviews at each stage of the design flow to catch and resolve issues early in the process. This helps in reducing the overall design time and cost.

-

Collaborate with the manufacturing team: Involve the manufacturing team early in the design process to ensure that the design is manufacturable and cost-effective. This helps in avoiding costly redesigns and delays in production.

-

Automate repetitive tasks: Use automation tools and scripts to streamline repetitive tasks, such as design rule checks and output generation. This helps in reducing the chances of human error and improving the overall efficiency of the design process.

-

Continuously improve the design flow: Regularly review and optimize the design flow based on feedback from the team and lessons learned from previous projects. This helps in continuously improving the quality and efficiency of the design process.

FAQs

-

What is the importance of a well-defined PCB design flow?

A well-defined PCB design flow ensures consistency, efficiency, quality, and cost-effectiveness in the design process. It helps in minimizing errors, reducing iterations, and delivering a high-quality product that meets the required specifications. -

What are the key stages of an optimum PCB design flow?

The key stages of an optimum PCB design flow include concept and feasibility study, schematic design, component placement, routing, design review and verification, and output generation. -

Why is it important to collaborate with the manufacturing team during the PCB design process?

Collaborating with the manufacturing team early in the design process helps in ensuring that the design is manufacturable and cost-effective. It helps in avoiding costly redesigns and delays in production. -

How can automation tools help in improving the efficiency of the PCB design process?

Automation tools and scripts can streamline repetitive tasks, such as design rule checks and output generation. This helps in reducing the chances of human error and improving the overall efficiency of the design process. -

What are some best practices for an optimum PCB design flow?

Some best practices for an optimum PCB design flow include establishing clear design requirements, using a version control system, following design guidelines, performing regular design reviews, collaborating with the manufacturing team, automating repetitive tasks, and continuously improving the design flow based on feedback and lessons learned.

| Stage | Key Activities |

|---|---|

| Concept and Feasibility Study | – Gathering customer requirements and specifications – Analyzing the feasibility of the design – Creating a high-level block diagram – Identifying critical components and technologies |

| Schematic Design | – Creating a hierarchical design structure – Selecting components and creating symbols – Defining the connectivity between components – Performing initial design rule checks (DRC) |

| Component Placement | – Defining the board outline and dimensions – Placing components based on their functional groups and interconnections – Optimizing the placement for signal integrity, thermal management, and manufacturability – Performing placement rule checks |

| Routing | – Defining the layer stack-up and routing constraints – Creating power and ground planes – Routing the signals based on their net classes and constraints – Optimizing the routing for signal integrity, EMI/EMC, and manufacturability – Performing routing rule checks |

| Design Review and Verification | – Performing a final design rule check (DRC) – Running signal integrity simulations – Conducting thermal and power analysis – Collaborating with the manufacturing team |

| Output Generation | – Generating Gerber files for each layer of the PCB – Creating drill files and fabrication drawings – Generating assembly files – Reviewing the output files |

Conclusion

An optimum PCB design flow is essential for delivering high-quality, reliable, and cost-effective PCBs. By following a well-defined design flow and adhering to best practices at each stage, designers can minimize errors, reduce iterations, and ensure that the final product meets the desired specifications. Collaboration with the manufacturing team, automation of repetitive tasks, and continuous improvement of the design flow are key strategies for optimizing the PCB design process.

By implementing an optimum PCB design flow, companies can streamline their design process, reduce time-to-market, and gain a competitive edge in the industry. As PCB technology continues to evolve, it is crucial for designers to stay updated with the latest design tools, techniques, and best practices to ensure the success of their projects.

Leave a Reply