Introduction to Small-Quantity PCB Manufacturing

In the world of electronics, printed circuit boards (PCBs) play a crucial role in connecting and supporting electronic components. PCBs are used in a wide range of applications, from small consumer devices to complex industrial systems. While mass production of PCBs is common for large-scale projects, there is also a significant demand for small-quantity PCB manufacturing. This is where RAYMING, a leading PCB manufacturer, excels in providing high-quality solutions for clients requiring small quantities of PCBs.

What is Small-Quantity PCB Manufacturing?

Small-quantity PCB manufacturing refers to the production of a limited number of PCBs, typically ranging from a few pieces to a few hundred. This approach is ideal for prototyping, testing, and small-scale production runs. Unlike mass production, which focuses on cost-effectiveness through large volumes, small-quantity PCB manufacturing prioritizes flexibility, speed, and customization.

Advantages of Small-Quantity PCB Manufacturing

-

Rapid Prototyping: Small-quantity PCB manufacturing enables designers and engineers to quickly prototype their designs and test functionality. This iterative process allows for faster design validation and refinement.

-

Cost-Effective for Low Volumes: When the required quantity of PCBs is low, small-quantity manufacturing becomes a cost-effective solution. It eliminates the need for large upfront investments and reduces the risk of overproduction.

-

Flexibility and Customization: Small-quantity PCB manufacturing offers greater flexibility in terms of design changes and customization. It allows for easy incorporation of modifications and improvements based on initial testing and feedback.

-

Faster Turnaround Times: With streamlined processes and dedicated resources, small-quantity PCB manufacturers can deliver finished products in shorter timeframes compared to mass production.

RAYMING: A Trusted Partner for Small-Quantity PCB Manufacturing

RAYMING is a well-established PCB manufacturer that specializes in providing high-quality small-quantity PCB solutions. With state-of-the-art facilities, experienced professionals, and a commitment to customer satisfaction, RAYMING has earned a reputation as a reliable partner for businesses and individuals seeking small-quantity PCBs.

Why Choose RAYMING for Small-Quantity PCB Manufacturing?

-

Expertise and Experience: RAYMING has a team of skilled engineers and technicians with extensive experience in PCB design and manufacturing. They possess the knowledge and expertise to handle projects of various complexities and requirements.

-

Advanced Manufacturing Capabilities: RAYMING invests in the latest manufacturing technologies and equipment to ensure the highest quality standards. Their facilities are equipped to handle a wide range of PCB types, including single-sided, double-sided, and multi-layer boards.

-

Stringent Quality Control: RAYMING follows rigorous quality control procedures throughout the manufacturing process. Each PCB undergoes thorough inspections and testing to ensure adherence to specifications and industry standards.

-

Rapid Turnaround Times: With optimized workflows and efficient processes, RAYMING can deliver small-quantity PCBs within short lead times. This enables clients to receive their products quickly and meet tight project deadlines.

-

Competitive Pricing: RAYMING offers competitive pricing for small-quantity PCB manufacturing without compromising on quality. They strive to provide cost-effective solutions that meet the budgetary constraints of their clients.

RAYMING’s Small-Quantity PCB Manufacturing Process

RAYMING follows a well-defined process to ensure the successful manufacturing of small-quantity PCBs:

-

Design Review: Upon receiving the PCB design files from the client, RAYMING’s engineering team carefully reviews the design to check for any potential issues or optimizations. They provide feedback and suggestions to enhance manufacturability and functionality.

-

Material Selection: RAYMING offers a wide range of PCB materials to suit different applications and requirements. They assist clients in selecting the most appropriate materials based on factors such as electrical properties, thermal stability, and mechanical strength.

-

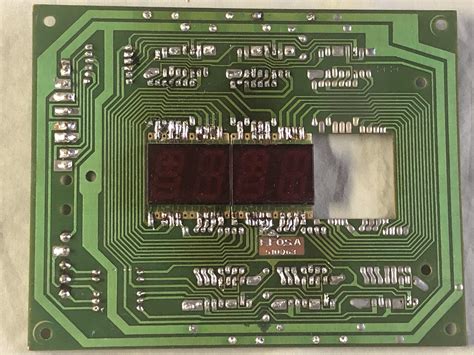

PCB Fabrication: Using advanced manufacturing techniques, RAYMING fabricates the PCBs according to the approved design. This includes processes such as copper etching, solder mask application, silkscreen printing, and surface finishes.

-

Assembly and Soldering: If required, RAYMING can also handle the assembly and soldering of electronic components onto the PCBs. Their skilled technicians follow industry best practices to ensure proper placement and secure connections.

-

Quality Inspection: Each manufactured PCB undergoes rigorous quality inspections to verify its conformance to specifications. This includes visual inspections, electrical testing, and functionality checks. Any issues or defects are promptly addressed and rectified.

-

Packaging and Delivery: Once the PCBs have passed all quality checks, they are carefully packaged to ensure safe transportation. RAYMING offers various shipping options to meet the client’s desired delivery timeline and budget.

Applications of Small-Quantity PCBs

Small-quantity PCBs find applications across various industries and sectors. Some common areas where small-quantity PCBs are utilized include:

-

Prototype Development: Small-quantity PCBs are extensively used in the prototyping phase of product development. They allow designers and engineers to test and validate their designs before proceeding to mass production.

-

Research and Development: In research and development settings, small-quantity PCBs are essential for experimenting with new concepts, technologies, and innovations. They provide a cost-effective means to explore and refine ideas.

-

Custom Electronics: Small-quantity PCBs are ideal for custom electronics projects where specific functionalities or form factors are required. They enable the creation of tailored solutions for niche applications.

-

Educational and Hobbyist Projects: Students, hobbyists, and DIY enthusiasts often rely on small-quantity PCBs for their projects and learning experiences. These PCBs allow them to bring their ideas to life and gain hands-on experience with electronics.

-

Small-Scale Production Runs: Some businesses and startups may require small-scale production runs of PCBs for their products. Small-quantity PCB manufacturing enables them to produce the necessary quantities without the need for large-scale investments.

RAYMING’s Commitment to Quality and Customer Satisfaction

At RAYMING, quality is of utmost importance. They understand that the success of their clients’ projects depends on the reliability and performance of the PCBs they manufacture. To ensure the highest quality standards, RAYMING implements several measures:

-

Certified Materials: RAYMING sources materials from reputable suppliers who adhere to industry certifications and standards. This ensures the consistency and reliability of the PCBs produced.

-

Strict Manufacturing Protocols: RAYMING follows strict manufacturing protocols to maintain quality throughout the production process. This includes temperature control, humidity monitoring, and contamination prevention measures.

-

Automated Inspection Systems: RAYMING employs automated inspection systems to detect any defects or anomalies in the PCBs. These systems use advanced imaging and analysis techniques to identify issues that may not be visible to the naked eye.

-

Trained and Skilled Workforce: RAYMING invests in the training and development of its workforce. Their team consists of skilled professionals who are well-versed in PCB manufacturing techniques and quality control procedures.

-

Continuous Improvement: RAYMING is committed to continuous improvement. They regularly review and update their processes, technologies, and best practices to enhance efficiency, reduce defects, and deliver superior products to their clients.

FAQ

- What is the minimum order quantity for small-quantity PCBs at RAYMING?

RAYMING accepts orders as low as a single piece for small-quantity PCB manufacturing. They understand the need for flexibility and accommodate the specific requirements of their clients.

- How long does it take to manufacture small-quantity PCBs at RAYMING?

The turnaround time for small-quantity PCBs at RAYMING varies depending on the complexity of the design and the specific requirements. However, they strive to deliver the finished products within the shortest possible timeframe, typically ranging from a few days to a couple of weeks.

- Can RAYMING handle complex PCB designs for small-quantity manufacturing?

Yes, RAYMING has the expertise and capabilities to handle complex PCB designs, including high-density interconnect (HDI) boards, flex PCBs, and rigid-flex PCBs. Their engineering team works closely with clients to ensure the manufacturability and functionality of the designs.

- Does RAYMING offer assembly services for small-quantity PCBs?

Yes, RAYMING provides assembly services for small-quantity PCBs. They can handle both through-hole and surface-mount assembly, depending on the client’s requirements. Their experienced technicians ensure precise placement and soldering of components.

- What is the cost of small-quantity PCB manufacturing at RAYMING?

The cost of small-quantity PCB manufacturing at RAYMING depends on various factors, such as the PCB size, layer count, material selection, and additional features. RAYMING offers competitive pricing and works with clients to provide cost-effective solutions that meet their budgetary constraints.

Conclusion

Small-quantity PCB manufacturing plays a vital role in enabling rapid prototyping, product development, and small-scale production runs. RAYMING, with its expertise, advanced manufacturing capabilities, and commitment to quality, stands out as a trusted partner for businesses and individuals seeking small-quantity PCBs.

By choosing RAYMING for small-quantity PCB manufacturing, clients can benefit from their experienced team, stringent quality control measures, and fast turnaround times. RAYMING’s dedication to customer satisfaction ensures that each PCB meets the highest standards of reliability and performance.

Whether it’s for prototyping, research and development, custom electronics, or small-scale production, RAYMING’s small-quantity PCB manufacturing services provide the flexibility, speed, and quality that clients need to bring their projects to life.

For more information about RAYMING’s small-quantity PCB manufacturing capabilities and to discuss your specific requirements, please visit their website or contact their sales team. RAYMING is committed to being your trusted partner in PCB manufacturing, delivering excellence in every small-quantity PCB they produce.

Leave a Reply