Understanding PCB Tolerances

PCB tolerances refer to the acceptable variations in the dimensions, spacing, and other physical characteristics of a printed circuit board. These tolerances are crucial in ensuring that the PCB functions as intended and fits properly within the designed enclosure. Adhering to well-defined tolerances helps minimize manufacturing defects, reduces assembly issues, and improves overall product quality.

The Importance of IPC Standards

The Association Connecting Electronics Industries (IPC) is a global trade association that develops and publishes industry standards for PCB design, fabrication, and assembly. These standards provide a common language and set of guidelines for manufacturers, designers, and customers to follow, ensuring consistency and reliability across the industry.

IPC standards cover various aspects of PCB manufacturing, including:

- Design and layout

- Material selection

- Fabrication processes

- Quality control and testing

- Acceptability criteria

By adhering to IPC standards, manufacturers like San Francisco Circuits can provide customers with high-quality PCBs that meet industry-recognized requirements.

San Francisco Circuits’ Updated PCB Tolerances

San Francisco Circuits has updated its PCB tolerances to reflect the latest IPC guidelines and standards. These updates encompass several key areas, ensuring that customers receive PCBs that meet or exceed industry expectations.

Board Thickness Tolerances

The thickness of a PCB is a critical factor in its performance and compatibility with other components. San Francisco Circuits’ updated tolerances for board thickness are as follows:

| Thickness (mm) | Tolerance (mm) |

|---|---|

| 0.4 – 0.8 | ± 0.1 |

| 0.8 – 1.6 | ± 0.15 |

| 1.6 – 2.4 | ± 0.2 |

| 2.4 – 3.2 | ± 0.25 |

| 3.2 – 4.0 | ± 0.3 |

These tolerances ensure that the PCBs maintain the required thickness for proper functionality and compatibility with other components.

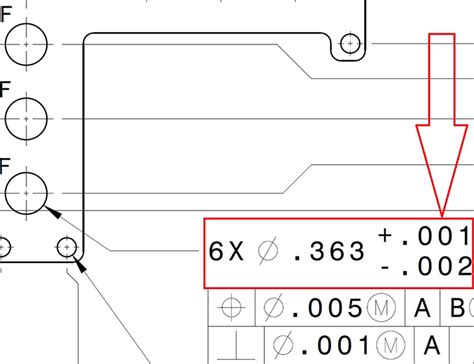

Hole Size Tolerances

The accuracy of hole sizes in a PCB is essential for component placement and solderability. San Francisco Circuits’ updated hole size tolerances are as follows:

| Hole Diameter (mm) | Tolerance (mm) |

|---|---|

| 0.3 – 0.5 | ± 0.08 |

| 0.5 – 1.0 | ± 0.1 |

| 1.0 – 1.5 | ± 0.15 |

| 1.5 – 2.0 | ± 0.2 |

| 2.0 – 3.0 | ± 0.25 |

These tolerances ensure that the holes in the PCB are accurately sized for component leads and provide a reliable electrical connection.

Copper Thickness Tolerances

The thickness of the copper layers in a PCB affects its electrical performance and current-carrying capacity. San Francisco Circuits’ updated copper thickness tolerances are as follows:

| Copper Weight (oz) | Thickness (µm) | Tolerance (µm) |

|---|---|---|

| 0.5 | 17.5 | ± 5 |

| 1.0 | 35 | ± 7 |

| 2.0 | 70 | ± 10 |

| 3.0 | 105 | ± 15 |

| 4.0 | 140 | ± 20 |

These tolerances ensure that the copper layers in the PCB have the appropriate thickness for optimal electrical performance and reliability.

Minimum Trace Width and Spacing

The width and spacing of traces on a PCB determine its signal integrity and manufacturability. San Francisco Circuits’ updated minimum trace width and spacing tolerances are as follows:

| Trace Width (mm) | Minimum Spacing (mm) |

|---|---|

| 0.1 | 0.1 |

| 0.15 | 0.15 |

| 0.2 | 0.2 |

| 0.25 | 0.25 |

| 0.3 | 0.3 |

These tolerances ensure that the traces on the PCB are properly sized and spaced for optimal signal integrity and manufacturability.

The Benefits of Adhering to IPC Standards and Tight Tolerances

By adhering to IPC standards and maintaining tight tolerances, San Francisco Circuits offers several benefits to its customers:

-

Improved Product Quality: PCBs manufactured within the specified tolerances are more likely to function as intended and have fewer defects, resulting in higher overall product quality.

-

Increased Reliability: Tight tolerances ensure that PCBs are consistent and reliable, reducing the risk of failures and improving the longevity of the final product.

-

Better Compatibility: PCBs manufactured to IPC standards and tolerances are more likely to be compatible with other components and systems, simplifying the assembly process and reducing the risk of integration issues.

-

Faster Time-to-Market: By providing PCBs that meet industry standards and tolerances, San Francisco Circuits helps its customers bring their products to market faster, without the need for extensive rework or troubleshooting.

-

Cost Savings: Adhering to tight tolerances and IPC standards helps minimize manufacturing defects and assembly issues, reducing the overall cost of PCB production and product development.

Frequently Asked Questions (FAQ)

-

Q: What are PCB tolerances, and why are they important?

A: PCB tolerances refer to the acceptable variations in the dimensions, spacing, and other physical characteristics of a printed circuit board. They are important because they ensure that the PCB functions as intended, fits properly within the designed enclosure, and is compatible with other components. -

Q: What is the role of IPC in setting PCB Standards?

A: IPC (Association Connecting Electronics Industries) is a global trade association that develops and publishes industry standards for PCB design, fabrication, and assembly. These standards provide a common language and set of guidelines for manufacturers, designers, and customers to follow, ensuring consistency and reliability across the industry. -

Q: How do San Francisco Circuits’ updated PCB tolerances benefit customers?

A: By adhering to IPC standards and maintaining tight tolerances, San Francisco Circuits offers its customers improved product quality, increased reliability, better compatibility, faster time-to-market, and cost savings. -

Q: What aspects of PCB manufacturing are covered by San Francisco Circuits’ updated tolerances?

A: San Francisco Circuits’ updated PCB tolerances cover several key areas, including board thickness, hole size, copper thickness, and minimum trace width and spacing. -

Q: How can customers ensure that their PCBs meet the required tolerances?

A: Customers can work closely with San Francisco Circuits throughout the design and manufacturing process to ensure that their PCBs meet the required tolerances. This includes providing accurate design files, selecting appropriate materials, and communicating any specific requirements or concerns to the manufacturing team.

Conclusion

San Francisco Circuits’ commitment to updating its PCB tolerances in accordance with IPC guidelines and standards demonstrates the company’s dedication to providing customers with the highest quality PCBs. By maintaining tight tolerances and adhering to industry standards, San Francisco Circuits ensures that its customers receive PCBs that are reliable, compatible, and cost-effective.

As the electronics industry continues to evolve, it is crucial for manufacturers like San Francisco Circuits to stay up-to-date with the latest standards and best practices. By doing so, they can help their customers bring innovative products to market faster, while maintaining the highest levels of quality and reliability.

Leave a Reply