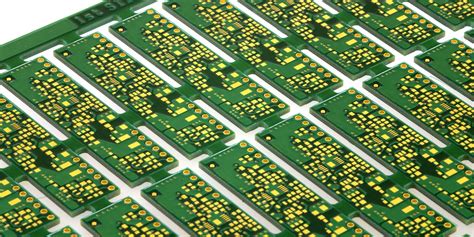

Introduction to Rapid PCB Prototypes

In the fast-paced world of electronics, time is of the essence. Businesses and engineers need to bring their ideas to life quickly and efficiently to stay ahead of the competition. This is where rapid PCB prototypes come into play. Printed Circuit Boards (PCBs) are the backbone of modern electronics, and the ability to create prototypes rapidly is crucial for success.

What are Rapid PCB Prototypes?

Rapid PCB prototypes are quickly manufactured printed circuit boards that allow engineers and designers to test and validate their designs before moving into full-scale production. These prototypes are created using advanced manufacturing techniques and materials, enabling quick turnaround times without compromising on quality.

Why are Rapid PCB Prototypes Important?

Rapid PCB prototypes play a vital role in the electronics industry for several reasons:

-

Faster Time-to-Market: By creating prototypes quickly, businesses can reduce the overall development time and bring their products to market faster.

-

Cost-Effective: Identifying and fixing issues early in the design process through rapid prototyping can save significant costs associated with large-scale production.

-

Design Validation: Prototypes allow engineers to test and validate their designs in real-world scenarios, ensuring the final product meets all requirements and specifications.

-

Iterative Improvement: With rapid prototyping, designers can make iterative improvements to their designs based on feedback and testing results, leading to a more refined final product.

The Benefits of Rapid PCB Prototyping

Reduced Development Time

One of the primary benefits of rapid PCB prototyping is the significant reduction in development time. Traditional PCB manufacturing methods can take weeks or even months, slowing down the entire product development process. With rapid prototyping, businesses can create functional prototypes within days, allowing them to test and validate their designs much faster.

Cost Savings

Rapid PCB prototyping can also lead to significant cost savings. By identifying and addressing design issues early in the development process, businesses can avoid the expensive costs associated with large-scale production of faulty PCBs. Prototyping allows for iterative improvements, ensuring that the final product is of high quality and meets all requirements, thus reducing the likelihood of costly rework or recalls.

Enhanced Design Flexibility

Rapid prototyping enables greater design flexibility. Engineers can experiment with different materials, components, and layouts to optimize their designs. This flexibility allows for more innovative and efficient PCB designs, as designers can quickly test and refine their ideas without the constraints of traditional manufacturing methods.

Improved Collaboration

Rapid PCB prototyping also facilitates better collaboration among team members. With physical prototypes, designers, engineers, and other stakeholders can provide valuable feedback and insights, leading to a more cohesive and effective design process. Prototypes also serve as a tangible representation of the design, making it easier to communicate ideas and concepts to clients or investors.

Rapid PCB Prototyping Techniques

Several techniques are used to create rapid PCB prototypes, each with its own advantages and limitations. Some of the most common techniques include:

3D Printing

3D printing has revolutionized the way prototypes are created. This technique involves creating a three-dimensional object by layering materials based on a digital model. For PCB prototyping, conductive materials such as metal-filled filaments or conductive inks can be used to create functional PCBs. 3D printing offers great design flexibility and can create complex geometries that are difficult to achieve with traditional manufacturing methods.

Laser Etching

Laser etching is another popular technique for rapid PCB prototyping. This process uses a high-powered laser to remove specific areas of a copper-clad substrate, creating the desired PCB layout. Laser etching is fast, precise, and can create fine details, making it suitable for high-density PCB designs.

CNC Milling

Computer Numerical Control (CNC) milling is a subtractive manufacturing technique that uses computer-controlled machines to remove material from a substrate, creating the desired PCB layout. CNC milling offers high precision and can create complex PCB designs with tight tolerances. This technique is particularly useful for creating prototypes with thicker copper layers or when using non-standard materials.

Comparison of Rapid Prototyping Techniques

| Technique | Advantages | Limitations |

|---|---|---|

| 3D Printing | – High design flexibility – Can create complex geometries – Suitable for low-volume prototypes |

– Limited material options – Lower resolution compared to other techniques – May require post-processing |

| Laser Etching | – Fast and precise – Can create fine details – Suitable for high-density designs |

– Limited material options – May require additional processing steps – Higher cost compared to 3D printing |

| CNC Milling | – High precision – Can create complex designs with tight tolerances – Suitable for thicker copper layers and non-standard materials |

– Slower compared to other techniques – Higher cost compared to 3D printing and laser etching – Requires specialized equipment and expertise |

Our Rapid PCB Prototyping Services

At our company, we understand the importance of rapid PCB prototyping in the electronics industry. That’s why we offer a range of services to help businesses and engineers bring their ideas to life quickly and efficiently.

State-of-the-Art Facilities

Our state-of-the-art facilities are equipped with the latest machinery and technology to create high-quality rapid PCB prototypes. We invest in advanced equipment to ensure that we can deliver prototypes with the highest level of precision and accuracy.

Experienced Team

Our team consists of experienced engineers and technicians who have a deep understanding of PCB design and manufacturing. They work closely with clients to understand their requirements and provide expert guidance throughout the prototyping process.

Flexible Manufacturing Options

We offer flexible manufacturing options to cater to the diverse needs of our clients. Whether you need a single prototype or a small batch, we can accommodate your requirements. We also offer a range of materials and finishes to suit different applications and budgets.

Quick Turnaround Times

We pride ourselves on our quick turnaround times. Our streamlined processes and advanced equipment allow us to create rapid PCB prototypes in as little as 24 hours, depending on the complexity of the design. This enables our clients to test and validate their designs quickly, reducing overall development time.

Competitive Pricing

We offer competitive pricing for our rapid PCB prototyping services. We understand that cost is an important factor for businesses, and we strive to provide high-quality services at a fair price. Our pricing structure is transparent, and we work with clients to find the most cost-effective solution for their needs.

Case Studies

Case Study 1: Automotive Electronics Manufacturer

An automotive electronics manufacturer approached us with a need for rapid PCB prototypes for a new vehicle infotainment system. The client required multiple iterations of the prototype to test and validate different features and functionalities.

Our team worked closely with the client to understand their requirements and created several prototypes using our 3D printing and laser etching techniques. The prototypes were delivered within days, allowing the client to test and refine their design quickly.

The final product was successfully launched in the market, and the client attributed the smooth development process to the rapid prototyping services provided by our company.

Case Study 2: Medical Device Startup

A medical device startup was developing a new wearable device for monitoring patient vitals. The device required a complex PCB design with high-density components and strict tolerances.

Our team utilized CNC milling to create the rapid PCB prototypes for the device. The high precision of CNC milling allowed us to create prototypes that met the strict tolerances required for the medical application.

The startup was able to test and validate their design quickly, and the final product received regulatory approval for use in healthcare settings. The client praised our team’s expertise and the quality of the prototypes provided.

Frequently Asked Questions (FAQ)

-

How long does it take to create a rapid PCB prototype?

The turnaround time for rapid PCB prototypes varies depending on the complexity of the design and the chosen manufacturing technique. However, we can create prototypes in as little as 24 hours for simple designs. More complex designs may take a few days. -

What materials can be used for rapid PCB prototyping?

We offer a range of materials for rapid PCB prototyping, including standard FR4, high-temperature materials, flexible substrates, and more. Our team can help you select the most suitable material for your application. -

Can you create prototypes with multiple layers?

Yes, we can create rapid PCB prototypes with multiple layers. Our advanced manufacturing techniques allow us to create prototypes with up to 16 layers, depending on the design requirements. -

What is the minimum quantity for ordering rapid PCB prototypes?

We have no minimum quantity requirements for rapid PCB prototypes. We can create single prototypes or small batches, depending on your needs. -

Do you offer design services for PCB prototypes?

Yes, our team of experienced engineers can provide design services for PCB prototypes. We can work with you to create a design from scratch or optimize an existing design for manufacturing.

Conclusion

Rapid PCB prototyping is a game-changer in the electronics industry. It enables businesses and engineers to bring their ideas to life quickly and efficiently, reducing development time and costs while improving design quality.

At our company, we are committed to providing high-quality rapid PCB prototyping services to our clients. With our state-of-the-art facilities, experienced team, flexible manufacturing options, quick turnaround times, and competitive pricing, we are the ideal partner for your prototyping needs.

Contact us today to learn more about how we can help you create rapid PCB prototypes and bring your electronics projects to fruition faster.

Leave a Reply