What is FR4 Material?

FR4 is a composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. The “FR” in its name stands for “Flame Retardant,” indicating its inherent resistance to fire. The “4” represents the specific grade of the material, which is determined by the National Electrical Manufacturers Association (NEMA) standards.

Composition of FR4

The two main components of FR4 are:

- Fiberglass cloth: This provides the material with its mechanical strength and dimensional stability.

- Epoxy resin: This acts as a binder, holding the fiberglass cloth together and providing electrical insulation properties.

The combination of these materials results in a laminate that possesses a desirable balance of mechanical, electrical, and thermal properties.

Key Properties of FR4

Mechanical Properties

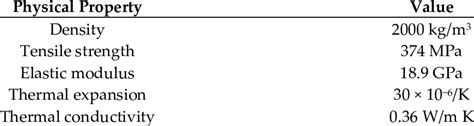

FR4 exhibits excellent mechanical properties, making it suitable for applications that require high strength and durability. Some of its key mechanical properties include:

- High tensile strength

- Good flexural strength

- High compressive strength

- Excellent dimensional stability

- Low water absorption

These properties allow FR4 to withstand the stresses and strains encountered during the manufacturing process and in various applications.

Tensile Strength

Tensile strength is a measure of a material’s ability to resist breaking under tension. FR4 has a high tensile strength, typically ranging from 310 to 380 MPa (45,000 to 55,000 psi), depending on the specific grade and thickness of the material.

Flexural Strength

Flexural strength, also known as bend strength, is a material’s ability to resist deformation under load. FR4 possesses good flexural strength, with values typically ranging from 415 to 585 MPa (60,000 to 85,000 psi), depending on the grade and thickness.

Compressive Strength

Compressive strength is a material’s ability to withstand compressive loads without failure. FR4 has a high compressive strength, typically ranging from 415 to 585 MPa (60,000 to 85,000 psi), making it suitable for applications that involve high compressive forces.

Dimensional Stability

Dimensional stability refers to a material’s ability to maintain its original dimensions when subjected to changes in temperature, humidity, or other environmental factors. FR4 exhibits excellent dimensional stability, with a coefficient of thermal expansion (CTE) of approximately 11-15 ppm/°C in the X and Y directions, and 50-70 ppm/°C in the Z direction.

Water Absorption

Water absorption is a measure of a material’s ability to absorb moisture from the environment. FR4 has low water absorption, typically less than 0.1% after 24 hours of immersion in water. This property is essential for maintaining the material’s dimensional stability and electrical insulation properties in humid environments.

Electrical Properties

FR4 is an excellent electrical insulator, making it suitable for use in electrical and electronic applications. Some of its key electrical properties include:

- High dielectric strength

- Low dielectric constant

- Low dissipation factor

- High insulation resistance

These properties ensure that FR4 can effectively insulate electrical components and minimize signal loss in PCBs.

Dielectric Strength

Dielectric strength is a measure of a material’s ability to withstand electric fields without breaking down. FR4 has a high dielectric strength, typically ranging from 20 to 28 kV/mm (500 to 700 V/mil), depending on the specific grade and thickness of the material.

Dielectric Constant

The dielectric constant, also known as relative permittivity, is a measure of a material’s ability to store electrical energy in an electric field. FR4 has a relatively low dielectric constant, typically ranging from 4.2 to 4.9 at 1 MHz, which helps minimize signal delay and distortion in high-frequency applications.

Dissipation Factor

The dissipation factor, also called loss tangent, is a measure of a material’s inefficiency in storing electrical energy. FR4 has a low dissipation factor, typically ranging from 0.02 to 0.03 at 1 MHz, which helps minimize energy loss and heat generation in electrical circuits.

Insulation Resistance

Insulation resistance is a measure of a material’s ability to resist the flow of electrical current. FR4 has a high insulation resistance, typically greater than 10^6 megaohms, ensuring excellent electrical insulation between conductors.

Thermal Properties

FR4 possesses good thermal properties, allowing it to withstand the heat generated by electrical components and maintain its performance in various temperature conditions. Some of its key thermal properties include:

- Glass transition temperature (Tg)

- Thermal conductivity

- Coefficient of thermal expansion (CTE)

- Flammability rating

These properties enable FR4 to perform reliably in a wide range of temperature environments and help dissipate heat from electrical components.

Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is the temperature at which a material transitions from a hard, glassy state to a soft, rubbery state. FR4 has a relatively high Tg, typically ranging from 130°C to 140°C (266°F to 284°F), allowing it to maintain its mechanical and electrical properties at elevated temperatures.

Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. FR4 has a relatively low thermal conductivity, typically ranging from 0.3 to 0.4 W/mK, which helps to insulate electrical components and minimize heat transfer between layers in a PCB.

Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion (CTE) is a measure of a material’s dimensional change in response to a change in temperature. FR4 has a CTE of approximately 11-15 ppm/°C in the X and Y directions, and 50-70 ppm/°C in the Z direction. This relatively low CTE helps to minimize thermal stresses and maintain the dimensional stability of PCBs.

Flammability Rating

FR4 is designed to be flame-retardant, with a flammability rating of UL 94 V-0. This rating indicates that the material self-extinguishes within 10 seconds after being exposed to a flame, and does not drip flaming particles that could ignite cotton placed below the sample. This flame-retardant property is crucial for ensuring the safety of electrical and electronic devices.

Uses of FR4

FR4 is widely used in various industries due to its excellent properties and versatility. Some of the main applications of FR4 include:

Printed Circuit Boards (PCBs)

FR4 is the most commonly used material for the production of PCBs. Its excellent electrical insulation properties, high mechanical strength, and good thermal stability make it an ideal substrate for mounting and interconnecting electronic components.

Single-sided PCBs

Single-sided PCBs have conductive traces on only one side of the FR4 substrate. These PCBs are typically used in simple, low-density electronic devices, such as power supplies, LED lighting, and basic control circuits.

Double-sided PCBs

Double-sided PCBs have conductive traces on both sides of the FR4 substrate, allowing for higher component density and more complex circuit designs. These PCBs are used in a wide range of applications, including consumer electronics, telecommunications equipment, and industrial control systems.

Multi-layer PCBs

Multi-layer PCBs consist of multiple layers of FR4 substrates, each with its own set of conductive traces, which are interconnected using plated through-holes (PTHs) or via. These PCBs are used in high-density, complex electronic devices, such as smartphones, computers, and medical equipment.

Electrical Insulation

FR4 is used as an electrical insulator in various applications, such as:

- Transformer boards

- Motor and generator insulation

- Switchgear and busbar insulation

- Terminal blocks and connectors

Its high dielectric strength, low dielectric constant, and excellent insulation resistance make FR4 an ideal choice for these applications.

Structural Components

FR4 can be used to create structural components in electrical and electronic devices, such as:

- Enclosures and housings

- Brackets and supports

- Gears and cams

- Spacers and standoffs

Its high mechanical strength, dimensional stability, and flame-retardant properties make FR4 suitable for these applications.

Advantages of FR4

FR4 offers several advantages over other materials used in electrical and electronic applications:

- Excellent electrical insulation properties

- High mechanical strength and dimensional stability

- Good thermal stability and flame-retardant properties

- Versatility in terms of thickness, copper cladding, and finishing options

- Cost-effectiveness compared to other high-performance materials

These advantages have made FR4 the go-to material for PCBs and other electrical insulation applications.

Disadvantages of FR4

Despite its many advantages, FR4 does have some limitations:

- Limited high-frequency performance due to its relatively high dielectric constant and dissipation factor

- Lower thermal conductivity compared to metal-based substrates, which can lead to heat build-up in high-power applications

- Susceptibility to moisture absorption, which can affect its electrical and mechanical properties over time

- Difficulty in machining and drilling due to its glass reinforcement, which can cause tool wear and tear

These limitations should be considered when selecting FR4 for a specific application.

FR4 Material Selection and Specification

When selecting FR4 for an application, it is essential to consider the specific requirements of the project, such as:

- Electrical requirements (e.g., dielectric strength, dielectric constant, insulation resistance)

- Mechanical requirements (e.g., tensile strength, flexural strength, dimensional stability)

- Thermal requirements (e.g., glass transition temperature, thermal conductivity, CTE)

- Environmental requirements (e.g., temperature range, humidity, chemical exposure)

Based on these requirements, the appropriate grade, thickness, and copper cladding of FR4 can be chosen. The most common grades of FR4 are:

- FR4 Standard (Grade 10): General-purpose grade with a Tg of 130°C

- FR4 High Tg (Grade 21): High-temperature grade with a Tg of 170°C

- FR4 Halogen-free (Grade S1000): Environmentally friendly grade without halogenated flame retardants

The thickness of FR4 can range from 0.2 mm to 3.2 mm (0.008 in to 0.126 in), depending on the application requirements. Copper cladding is available in various weights, typically ranging from 0.5 oz/ft² to 3 oz/ft² (17 µm to 105 µm).

Processing and Manufacturing Considerations

When working with FR4, several processing and manufacturing considerations should be taken into account:

- Drilling: FR4 requires specialized drill bits and parameters to minimize tool wear and ensure clean, accurate holes.

- Plating: The glass reinforcement in FR4 can affect the adhesion of plated through-holes (PTHs) and vias, requiring proper surface preparation and plating techniques.

- Soldering: FR4 is compatible with various Soldering Methods, including Wave Soldering, reflow soldering, and hand soldering. However, the appropriate temperature profiles and solder materials must be used to avoid damage to the material.

- Cleaning: FR4 is resistant to most common cleaning agents, but care should be taken to avoid harsh chemicals that can degrade the material over time.

By understanding these processing and manufacturing considerations, manufacturers can ensure the optimal performance and reliability of FR4-based products.

Future Trends and Developments

As the electronics industry continues to evolve, there is a growing demand for materials that can provide enhanced performance and functionality. Some of the future trends and developments related to FR4 include:

- High-speed materials: Modified FR4 formulations with lower dielectric constants and dissipation factors are being developed to support higher signal speeds and frequencies.

- Thermal management: New FR4 variants with higher thermal conductivity and lower CTE are being explored to improve heat dissipation and minimize thermal stresses in high-power applications.

- Environmentally friendly materials: There is a growing focus on developing halogen-free and bio-based FR4 alternatives to reduce the environmental impact of electronic products.

- Additive manufacturing: The use of FR4 in 3D printing and other additive manufacturing techniques is being investigated to enable rapid prototyping and customization of electronic components.

As these trends and developments continue to shape the industry, FR4 is likely to remain a key material in the production of PCBs and other electronic components.

Conclusion

FR4 is a versatile and high-performance material that plays a crucial role in the electronics industry. Its excellent electrical, mechanical, and thermal properties make it an ideal choice for a wide range of applications, from PCBs to structural components. By understanding the properties, uses, and processing considerations of FR4, manufacturers can leverage its benefits to create reliable, cost-effective, and high-quality electronic products.

As the industry evolves, FR4 will likely continue to adapt and improve to meet the changing demands of electronic devices. With ongoing research and development efforts focused on enhancing its performance and environmental sustainability, FR4 is poised to remain a key material in the electronics industry for years to come.

Frequently Asked Questions (FAQ)

-

What does FR4 stand for?

FR4 stands for “Flame Retardant 4,” indicating that it is a flame-retardant material. The “4” represents the specific grade of the material, which is determined by the National Electrical Manufacturers Association (NEMA) standards. -

What is the difference between FR4 and G10?

FR4 and G10 are both glass-reinforced epoxy laminate materials, but they differ in their flame-retardant properties. FR4 contains flame-retardant additives, while G10 does not. As a result, FR4 has a higher flame resistance rating (UL 94 V-0) compared to G10. -

Can FR4 be used for high-frequency applications?

While FR4 is suitable for many general-purpose applications, its relatively high dielectric constant and dissipation factor can limit its performance in high-frequency applications. For high-speed and high-frequency designs, specialized materials with lower dielectric constants and dissipation factors, such as Rogers or Isola materials, may be more appropriate. -

Is FR4 suitable for outdoor or harsh environments?

FR4 has good resistance to moisture, chemicals, and temperature variations, making it suitable for many outdoor and harsh environment applications. However, for extreme conditions, such as prolonged exposure to high humidity or corrosive chemicals, specialized grades of FR4 or alternative materials may be required. -

Can FR4 be recycled?

FR4 is not easily recyclable due to its composite nature, consisting of fiberglass and epoxy resin. However, efforts are being made to develop more environmentally friendly alternatives, such as halogen-free and bio-based FR4 materials, which can reduce the environmental impact of electronic waste.

Leave a Reply