Why Choose RAYMING for Your PCB Prototype Needs?

There are several reasons why RAYMING stands out as a top choice for PCB prototyping:

Expertise and Experience

RAYMING has a team of highly skilled engineers and technicians who possess extensive knowledge and experience in PCB design, fabrication, and assembly. This expertise ensures that your PCB prototype is designed and manufactured to the highest standards, meeting your specific requirements and industry regulations.

State-of-the-Art Technology

RAYMING invests in the latest technology and equipment to deliver superior PCB prototypes. The company utilizes advanced software tools for PCB design, such as Altium Designer and OrCAD, to create accurate and optimized layouts. Additionally, RAYMING employs state-of-the-art manufacturing processes, including surface mount technology (SMT) and through-hole technology (THT), to ensure the quality and reliability of your PCB prototype.

Quick Turnaround Time

RAYMING understands the importance of timely delivery in the fast-paced world of electronics. The company offers quick turnaround times for PCB prototypes, ensuring that you receive your boards in a timely manner to meet your project deadlines. RAYMING’s streamlined processes and efficient workflow enable them to deliver high-quality PCB prototypes within short lead times.

Competitive Pricing

RAYMING offers competitive pricing for its PCB prototyping services, making it an affordable option for businesses and individuals alike. The company’s cost-effective solutions are achieved through optimized manufacturing processes, economies of scale, and strong relationships with suppliers. RAYMING strives to provide value for money without compromising on quality.

Flexible Manufacturing Options

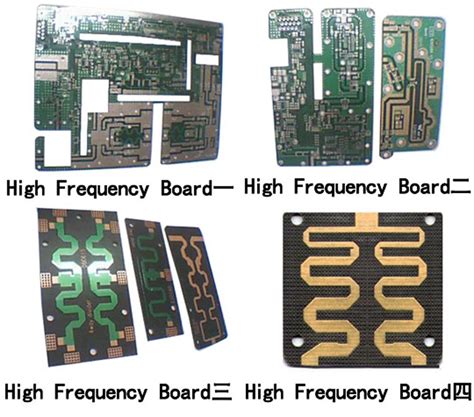

RAYMING offers a range of manufacturing options to cater to your specific needs. Whether you require single-sided, double-sided, or multi-layer PCBs, RAYMING has the capability to fabricate them. The company also offers various PCB materials, such as FR-4, Rogers, and high-temperature substrates, to suit different applications and operating environments.

RAYMING’s PCB Prototyping Process

RAYMING follows a well-defined process to ensure the successful delivery of your PCB prototype. The process involves the following steps:

-

Design Review: RAYMING’s experienced engineers review your PCB design files to ensure they meet manufacturability standards and identify any potential issues. They provide feedback and suggestions for improvement, helping you optimize your design for production.

-

Material Selection: Based on your requirements and the intended application, RAYMING helps you select the appropriate PCB material. The company offers a wide range of materials, including standard FR-4, high-frequency materials like Rogers, and specialized substrates for high-temperature or high-reliability applications.

-

PCB Fabrication: Once the design is finalized and materials are selected, RAYMING proceeds with the fabrication of your PCB prototype. The company uses advanced manufacturing techniques, such as computer numerical control (CNC) drilling, plating, and etching, to create the PCB according to your specifications.

-

PCB Assembly: If required, RAYMING can also assemble your PCB prototype. The company offers both SMT and THT assembly services, using high-quality components sourced from reliable suppliers. RAYMING’s experienced technicians ensure precise placement and soldering of components on the PCB.

-

Quality Control: RAYMING maintains stringent quality control measures throughout the PCB prototyping process. Each PCB undergoes rigorous testing and inspection to ensure it meets the required specifications and functions as intended. This includes visual inspection, electrical testing, and functional testing.

-

Packaging and Shipping: Once your PCB prototype passes the quality control checks, RAYMING carefully packages it to protect it during shipping. The company offers various shipping options to meet your delivery preferences and ensures that your PCB prototype reaches you safely and on time.

PCB Prototype Specifications

RAYMING offers a wide range of PCB prototype specifications to cater to different customer requirements. The following table provides an overview of the key specifications:

| Specification | Options |

|---|---|

| PCB Layers | 1-16 layers |

| PCB Material | FR-4, Rogers, High-Temp, etc. |

| PCB Thickness | 0.4mm – 3.2mm |

| Copper Thickness | 0.5oz – 6oz |

| Minimum Hole Size | 0.2mm |

| Minimum Line Width | 0.1mm |

| Surface Finish | HASL, ENIG, OSP, Immersion Gold, etc. |

| Solder Mask Color | Green, Red, Blue, Black, White, Yellow |

| Silkscreen Color | White, Black, Yellow |

| PCB Dimensions | Up to 500mm x 500mm |

RAYMING’s flexible manufacturing capabilities allow them to accommodate a wide range of PCB prototype specifications. If you have specific requirements not listed in the table above, RAYMING’s team of experts can work with you to find a suitable solution.

Benefits of Working with RAYMING for PCB Prototyping

Partnering with RAYMING for your PCB prototyping needs offers several benefits:

-

Faster Time-to-Market: RAYMING’s quick turnaround times and efficient processes help you accelerate your product development cycle, enabling you to bring your products to market faster.

-

Cost Savings: RAYMING’s competitive pricing and cost-effective solutions help you save on PCB prototyping costs without compromising on quality. This allows you to allocate your resources more effectively and maximize your return on investment.

-

Improved Product Quality: RAYMING’s expertise, advanced technology, and stringent quality control measures ensure that your PCB prototype is of the highest quality. This reduces the risk of defects and failures, leading to improved product reliability and performance.

-

Flexibility and Customization: RAYMING offers a wide range of PCB prototyping options and specifications, allowing you to customize your prototype to meet your specific requirements. This flexibility enables you to create PCBs that are tailored to your application and operating environment.

-

Expert Support: RAYMING’s experienced team of engineers and technicians provides expert support throughout the PCB prototyping process. They offer design assistance, material selection guidance, and technical support to ensure the success of your project.

Frequently Asked Questions (FAQ)

-

Q: What is the minimum order quantity for PCB prototypes at RAYMING?

A: RAYMING offers low minimum order quantities for PCB prototypes, starting from just 5 pieces. This allows you to order small quantities for testing and validation before committing to larger production runs. -

Q: How long does it take to receive my PCB prototype from RAYMING?

A: RAYMING offers quick turnaround times for PCB prototypes. The standard lead time is 5-7 days, but expedited options are available for urgent requirements. The actual lead time may vary depending on the complexity of your design and the manufacturing options selected. -

Q: Can RAYMING assist with PCB design and layout?

A: Yes, RAYMING offers PCB design and layout services. The company has a team of experienced engineers who can help you design and optimize your PCB layout for manufacturability and performance. They use industry-standard software tools and follow best practices to ensure the quality of your PCB design. -

Q: Does RAYMING offer assembly services for PCB prototypes?

A: Yes, RAYMING offers both SMT and THT assembly services for PCB prototypes. The company has the capability to assemble a wide range of components, including BGA, QFP, and fine-pitch devices. RAYMING’s experienced technicians ensure precise placement and soldering of components on your PCB prototype. -

Q: What certifications and quality standards does RAYMING adhere to?

A: RAYMING is committed to maintaining the highest quality standards in PCB prototyping. The company is ISO 9001 certified, ensuring that its processes and procedures meet international quality management standards. Additionally, RAYMING complies with industry-specific standards such as IPC and RoHS, ensuring that your PCB prototype meets the required specifications and regulations.

Conclusion

RAYMING is a trusted partner for businesses and individuals seeking high-quality PCB prototypes. With its expertise, advanced technology, quick turnaround times, and competitive pricing, RAYMING delivers satisfactory PCB prototypes that meet your specific requirements. By choosing RAYMING for your PCB prototyping needs, you can accelerate your product development cycle, save costs, and ensure the quality and reliability of your electronic designs.

Whether you are a startup, a small business, or a large enterprise, RAYMING has the capabilities and flexibility to cater to your PCB prototyping needs. With its commitment to customer satisfaction and continuous improvement, RAYMING is well-positioned to support your current and future PCB prototyping projects.

To get started with RAYMING for your PCB prototype, visit their website at www.rayming.com or contact their sales team at [email protected]. Experience the difference that RAYMING can make in bringing your electronic designs to life.

Leave a Reply