Introduction to Thru-hole Pad Classification

Thru-hole pad classification is an essential aspect of printed circuit board (PCB) manufacturing and assembly. It involves categorizing the different types of soldered thru-hole pads based on their characteristics, such as size, shape, and intended purpose. Accurate classification of thru-hole pads is crucial for ensuring the proper functionality and reliability of electronic devices.

In this article, we will explore the various classifications of soldered thru-hole pads, their applications, and the importance of proper classification in the PCB industry.

Types of Thru-hole Pads

Thru-hole pads can be classified into several categories based on their physical attributes and intended use. Here are the main types of thru-hole pads:

1. Standard Thru-hole Pads

Standard thru-hole pads are the most common type of pads used in PCB assembly. They are characterized by a circular shape and a hole in the center, which allows the leads of through-hole components to pass through and be soldered onto the pad. Standard thru-hole pads come in various sizes, depending on the component lead diameter and the current carrying capacity required.

| Pad Diameter (mm) | Hole Diameter (mm) | Current Capacity (A) |

|---|---|---|

| 1.0 | 0.6 | 1.0 |

| 1.5 | 0.8 | 2.0 |

| 2.0 | 1.0 | 3.0 |

| 2.5 | 1.2 | 4.0 |

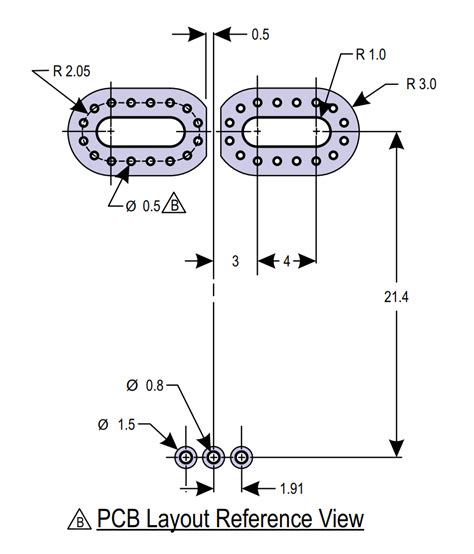

2. Elongated Thru-hole Pads

Elongated thru-hole pads, also known as oval pads, are used when more soldering area is required for better mechanical strength or increased current carrying capacity. These pads have an elongated shape, with the hole positioned off-center. Elongated pads are commonly used for connectors, power supply pins, or other components that experience higher mechanical stress or electrical load.

3. Thermal Relief Pads

Thermal relief pads are designed to improve the solderability of thru-hole components by reducing the thermal mass around the pad. They feature a circular pad with a cross-shaped cut-out pattern, which allows heat to dissipate more efficiently during the soldering process. Thermal relief pads are particularly useful for components with large thermal mass, such as power transistors or heat sinks.

4. Plated Thru-holes (PTHs)

Plated thru-holes (PTHs) are a special type of thru-hole pad that provide electrical and mechanical connection between layers of a multi-layer PCB. PTHs are created by drilling a hole through the PCB and then plating the hole wall with a conductive material, such as copper. PTHs are essential for creating reliable interconnections between different layers of a PCB.

Importance of Proper Thru-hole Pad Classification

Proper classification of thru-hole pads is crucial for several reasons:

-

Manufacturability: Accurate classification ensures that the appropriate pad size and shape are used for each component, facilitating the manufacturing process and reducing the risk of assembly errors.

-

Reliability: Using the correct pad type for each component enhances the mechanical strength and electrical performance of the soldered connection, improving the overall reliability of the electronic device.

-

Design Optimization: By selecting the appropriate pad classification, designers can optimize the PCB layout for factors such as current carrying capacity, thermal management, and signal integrity.

-

Cost Reduction: Proper pad classification helps minimize the use of unnecessary or oversized pads, leading to more efficient use of PCB real estate and potentially reducing manufacturing costs.

Guidelines for Thru-hole Pad Classification

When classifying thru-hole pads, consider the following guidelines:

-

Component Requirements: Evaluate the specific requirements of each component, such as lead diameter, mechanical stress, and electrical load, to determine the appropriate pad classification.

-

PCB Fabrication Capabilities: Consider the capabilities and limitations of the PCB fabrication process, including the minimum hole size, pad diameter, and spacing that can be reliably manufactured.

-

Industry Standards: Adhere to industry standards and guidelines, such as IPC-2222, which provide recommendations for pad sizes and spacing based on component lead diameter and PCB thickness.

-

Design for Manufacturing (DFM): Collaborate with PCB manufacturers and assembly providers to ensure that the selected pad classifications are compatible with their processes and equipment, minimizing the risk of manufacturing issues.

Frequently Asked Questions (FAQ)

1. What is the difference between a standard thru-hole pad and an elongated pad?

A standard thru-hole pad has a circular shape with the hole positioned at the center, while an elongated pad has an oval shape with the hole positioned off-center. Elongated pads provide more soldering area for better mechanical strength or increased current carrying capacity.

2. When should I use thermal relief pads?

Thermal relief pads are recommended for components with large thermal mass, such as power transistors or heat sinks. They help improve solderability by reducing the thermal mass around the pad, allowing heat to dissipate more efficiently during the soldering process.

3. What are plated thru-holes (PTHs) used for?

Plated thru-holes (PTHs) are used to create electrical and mechanical connections between layers of a multi-layer PCB. They are essential for establishing reliable interconnections between different layers of the PCB.

4. How do I determine the appropriate pad size for a component?

To determine the appropriate pad size for a component, consider factors such as the component lead diameter, mechanical stress, electrical load, and PCB fabrication capabilities. Consult industry standards, such as IPC-2222, for recommended pad sizes based on these factors.

5. Why is proper thru-hole pad classification important?

Proper thru-hole pad classification is important for several reasons, including improved manufacturability, enhanced reliability, design optimization, and potential cost reduction. Accurate classification ensures that the appropriate pad size and shape are used for each component, facilitating the manufacturing process and improving the overall performance of the electronic device.

Conclusion

Thru-hole pad classification is a critical aspect of PCB design and assembly. By understanding the different types of thru-hole pads and their applications, designers can make informed decisions when selecting the appropriate pad classification for each component. Proper pad classification ensures manufacturability, reliability, and optimal performance of the electronic device.

When classifying thru-hole pads, it is essential to consider component requirements, PCB fabrication capabilities, industry standards, and design for manufacturing principles. By collaborating with PCB manufacturers and adhering to established guidelines, designers can minimize the risk of manufacturing issues and ensure the successful production of high-quality electronic devices.

As technology continues to evolve, the importance of accurate thru-hole pad classification will remain paramount in the PCB industry. By staying informed about the latest developments and best practices in pad classification, designers and manufacturers can stay ahead of the curve and deliver innovative, reliable, and cost-effective electronic solutions.

Leave a Reply