PCB Substrate Materials

The substrate is the base material of a PCB, providing mechanical support and electrical insulation for the components and conductive traces. Common substrate materials include:

| Material | Description | Applications |

|---|---|---|

| FR-4 | Glass-reinforced epoxy laminate | General-purpose PCBs |

| CEM-1 | Composite epoxy material | Low-cost consumer electronics |

| Polyimide | High-temperature resistant polymer | Aerospace and military applications |

| Teflon | Low dielectric constant and high thermal stability | High-frequency applications |

FR-4 Substrate

FR-4 is the most widely used substrate material in PCB manufacturing. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin binder. FR-4 offers excellent mechanical strength, electrical insulation, and thermal stability, making it suitable for a wide range of applications.

CEM-1 Substrate

CEM-1 (Composite Epoxy Material) is a lower-cost alternative to FR-4. It consists of a non-woven fiberglass mat impregnated with an epoxy resin binder. CEM-1 is often used in consumer electronics and other cost-sensitive applications where high-performance is not critical.

Copper Foil

Copper foil is the conductive layer bonded to the PCB substrate, forming the traces, pads, and planes that interconnect components. The thickness of the copper foil is typically measured in ounces per square foot (oz/ft²) or microns (μm).

| Thickness (oz/ft²) | Thickness (μm) | Applications |

|---|---|---|

| 0.5 | 17.5 | Low-power, high-density designs |

| 1 | 35 | General-purpose PCBs |

| 2 | 70 | High-current, power electronics |

Electrodeposited Copper Foil

Electrodeposited (ED) copper foil is produced by electroplating copper onto a rotating drum and then peeling it off. ED copper foil has a smooth surface on one side and a rough surface on the other, promoting adhesion to the substrate.

Rolled Copper Foil

Rolled copper foil is manufactured by rolling copper ingots into thin sheets. It has a more uniform thickness and grain structure compared to ED copper foil, making it suitable for high-frequency applications and fine-pitch designs.

Solder Mask

Solder mask is a protective coating applied to the PCB surface, covering the copper traces while leaving the pads and other areas exposed for soldering. It prevents solder bridges, protects the copper from oxidation, and provides electrical insulation.

| Color | Description |

|---|---|

| Green | Most common color, provides good contrast |

| Blue | Aesthetically pleasing, used in consumer electronics |

| Red | High-contrast, used in military and aerospace applications |

| Black | Used for aesthetic purposes or to minimize light reflection |

Liquid Photoimageable Solder Mask (LPI)

LPI solder mask is applied as a liquid photopolymer and then exposed to UV light through a photographic film. The unexposed areas are then developed and removed, leaving the desired solder mask pattern.

Dry Film Solder Mask

Dry film solder mask is a solid photopolymer film laminated onto the PCB surface. It is exposed to UV light through a photomask and then developed, similar to the LPI process. Dry film solder mask is typically used for simpler designs or prototyping.

Silkscreen

Silkscreen, also known as legend or nomenclature, is a printed layer on the PCB surface that provides component identification, orientation marks, and other visual information. It is typically printed using white or yellow ink on top of the solder mask.

| Ink Color | Description |

|---|---|

| White | Most common color, provides good contrast |

| Yellow | High-visibility, used in military and aerospace applications |

| Black | Used on white or light-colored solder masks |

Epoxy Ink

Epoxy-based inks are the most common type used for silkscreen printing. They offer good adhesion, durability, and resistance to solvents and abrasion.

UV Curable Ink

UV curable inks are growing in popularity due to their fast curing time and environmental friendliness. They are cured using UV light, resulting in a hard and durable finish.

Surface Finish

The surface finish is applied to the exposed copper pads and other areas of the PCB to protect them from oxidation and enhance solderability. Common surface finishes include:

| Finish | Description | Shelf Life |

|---|---|---|

| HASL | Hot Air Solder Leveling, tin-lead alloy | 12+ months |

| ENIG | Electroless Nickel Immersion Gold | 12+ months |

| IAg | Immersion Silver | 6-12 months |

| OSP | Organic Solderability Preservative | 3-6 months |

HASL (Hot Air Solder Leveling)

HASL is a traditional surface finish that involves dipping the PCB in a molten tin-lead alloy and then using hot air to level the surface. It provides good solderability and is cost-effective, but can result in uneven surfaces and is not suitable for fine-pitch components.

ENIG (Electroless Nickel Immersion Gold)

ENIG is a two-layer surface finish consisting of a nickel underlayer and a thin gold top layer. The nickel provides a diffusion barrier and the gold protects the nickel from oxidation. ENIG offers excellent solderability, a flat surface, and good shelf life, making it suitable for fine-pitch components and high-reliability applications.

Through-Hole Components

Through-hole components have leads that are inserted into holes drilled in the PCB and soldered on the opposite side. Common through-hole components include:

- Resistors

- Capacitors

- Inductors

- Connectors

- DIP (Dual Inline Package) ICs

Axial-Lead Components

Axial-lead components, such as resistors and diodes, have leads extending from either end of the component body. They are inserted into holes perpendicular to the PCB surface.

Radial-Lead Components

Radial-lead components, such as capacitors and inductors, have leads extending from one side of the component body. They are inserted into holes parallel to the PCB surface.

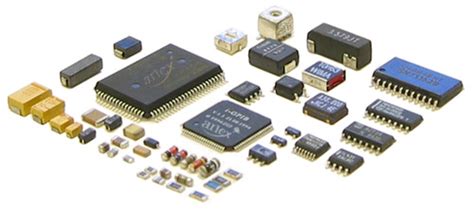

Surface Mount Components

Surface mount components are mounted directly onto the surface of the PCB, without the need for through-holes. They have smaller footprints and allow for higher component density compared to through-hole components. Common surface mount components include:

- Resistors

- Capacitors

- Inductors

- SOT (Small Outline Transistor) packages

- QFP (Quad Flat Package) ICs

- BGA (Ball Grid Array) ICs

Passive Surface Mount Components

Passive surface mount components, such as resistors, capacitors, and inductors, are available in various package sizes, such as 0402, 0603, and 0805. These numbers refer to the component dimensions in hundredths of an inch.

Active Surface Mount Components

Active surface mount components, such as ICs, are available in a variety of packages, including:

- SOT (Small Outline Transistor)

- SOIC (Small Outline Integrated Circuit)

- QFP (Quad Flat Package)

- BGA (Ball Grid Array)

These packages offer different lead counts, pitches, and thermal characteristics to suit specific application requirements.

Frequently Asked Questions (FAQ)

-

What is the difference between through-hole and surface mount components?

Through-hole components have leads that are inserted into holes drilled in the PCB, while surface mount components are mounted directly onto the surface of the PCB without the need for holes. -

What is the purpose of solder mask on a PCB?

Solder mask is a protective coating applied to the PCB surface that covers the copper traces while leaving the pads and other areas exposed for soldering. It prevents solder bridges, protects the copper from oxidation, and provides electrical insulation. -

What are the advantages of using ENIG surface finish?

ENIG (Electroless Nickel Immersion Gold) offers several advantages, including excellent solderability, a flat surface, good shelf life, and compatibility with fine-pitch components. It also provides a diffusion barrier (nickel) and protection against oxidation (gold). -

How do I choose the right substrate material for my PCB?

The choice of substrate material depends on the specific application requirements, such as thermal stability, electrical insulation, and cost. FR-4 is the most common substrate material and is suitable for a wide range of applications, while other materials like polyimide or Teflon are used for specialized applications with high-temperature or high-frequency requirements. -

What are the common package sizes for passive surface mount components?

Common package sizes for passive surface mount components include 0402, 0603, and 0805. These numbers refer to the component dimensions in hundredths of an inch. For example, a 0603 package measures 0.06 inches by 0.03 inches.

Conclusion

PCB manufacturing involves a wide range of components, each serving a specific purpose in creating reliable and efficient electronic devices. From substrate materials and copper foil to solder mask and surface finishes, understanding the role of each component is crucial for designing and manufacturing high-quality PCBs.

By selecting the appropriate components based on the application requirements, designers can ensure optimal performance, reliability, and cost-effectiveness. As technology advances, new materials and components will continue to emerge, enabling the development of even more sophisticated and compact electronic devices.

Leave a Reply