Introduction to Prepreg and Core in PCB Manufacturing

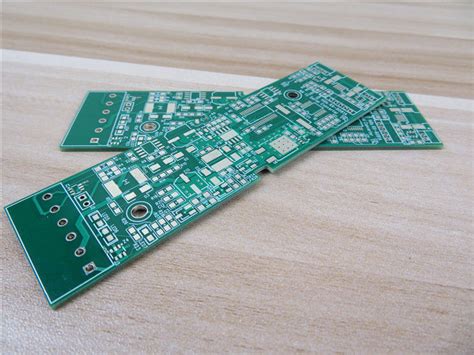

Printed Circuit Boards (PCBs) are essential components in modern electronics, forming the backbone of various devices and systems. The manufacturing process of PCBs involves several key materials, among which prepreg and core play crucial roles. In this article, we will delve into the world of prepreg and core, exploring their properties, applications, and significance in the PCB manufacturing industry.

What is Prepreg?

Prepreg, short for pre-impregnated, is a composite material used in the production of multilayer PCBs. It consists of a reinforcement fabric, typically glass fiber, impregnated with a partially cured thermoset resin, such as epoxy or polyimide. The resin is in a semi-solid state, allowing it to be malleable and easily shaped during the PCB manufacturing process.

Properties of Prepreg

Prepreg exhibits several key properties that make it an ideal material for PCB manufacturing:

- High mechanical strength: The reinforcement fabric provides excellent tensile strength and dimensional stability to the prepreg.

- Thermal stability: Prepreg maintains its structural integrity even at elevated temperatures encountered during the PCB lamination process.

- Electrical insulation: The thermoset resin imparts excellent electrical insulation properties to the prepreg, preventing short circuits between conductive layers.

- Adhesive properties: The partially cured resin in prepreg acts as an adhesive, bonding the layers of the PCB together during lamination.

Types of Prepreg

Prepreg comes in various types, each with specific properties tailored to different PCB applications:

| Prepreg Type | Description |

|---|---|

| FR-4 | Most common, glass fabric reinforced epoxy resin |

| High Tg | Higher glass transition temperature for improved thermal stability |

| Halogen-free | Environmentally friendly, without halogenated flame retardants |

| Low Dk/Df | Low dielectric constant and dissipation factor for high-frequency applications |

What is Core?

Core, also known as core laminate or base material, is a fundamental component in the construction of PCBs. It serves as the rigid foundation upon which the conductive layers and components are built. Core consists of a reinforcement material, typically glass fiber, impregnated with a fully cured thermoset resin.

Properties of Core

Core possesses several important properties that contribute to the overall performance of PCBs:

- Mechanical stability: The fully cured resin provides a rigid and stable base for the PCB, preventing warping and twisting.

- Electrical insulation: Like prepreg, the thermoset resin in core offers excellent electrical insulation properties.

- Heat dissipation: Core aids in the dissipation of heat generated by the components mounted on the PCB.

- Dimensional accuracy: The rigid nature of core ensures precise dimensional control during the PCB manufacturing process.

Types of Core

Core materials are available in various grades and thicknesses to cater to different PCB requirements:

| Core Type | Description |

|---|---|

| FR-4 | Most common, glass fabric reinforced epoxy resin |

| High Tg | Higher glass transition temperature for improved thermal stability |

| Halogen-free | Environmentally friendly, without halogenated flame retardants |

| Metal-core | Aluminum or copper core for enhanced heat dissipation |

The Role of Prepreg and Core in PCB Manufacturing

Prepreg and core play distinct yet complementary roles in the PCB manufacturing process. Let’s explore how these materials are used and their significance in creating reliable and high-performance PCBs.

Multilayer PCB Construction

Multilayer PCBs are constructed by alternating layers of prepreg and core, with conductive copper foil laminated on the outer surfaces. The number of layers in a PCB can vary depending on the complexity and requirements of the application.

Prepreg as an Adhesive and Insulator

During the PCB lamination process, prepreg acts as both an adhesive and an insulator between the layers. The partially cured resin in prepreg melts and flows under heat and pressure, bonding the layers together and filling any voids. This creates a solid, cohesive structure with excellent interlaminar adhesion.

Core as a Rigid Foundation

Core serves as the rigid foundation for the PCB, providing mechanical stability and maintaining the dimensional accuracy of the board. The fully cured resin in core prevents warping and twisting, ensuring that the PCB remains flat and stable throughout its lifetime.

Controlled Impedance and Signal Integrity

Prepreg and core play crucial roles in controlling the impedance and maintaining signal integrity in high-speed PCBs.

Dielectric Properties

The dielectric properties of prepreg and core, such as dielectric constant (Dk) and dissipation factor (Df), significantly influence the signal propagation and integrity in PCBs. Low Dk and Df materials are preferred for high-frequency applications to minimize signal loss and distortion.

Impedance Control

By carefully selecting the thickness and dielectric properties of prepreg and core, PCB designers can achieve controlled impedance in the signal traces. This is essential for maintaining signal integrity and preventing unwanted reflections and crosstalk.

Thermal Management

Effective thermal management is critical for the reliable operation of PCBs, especially in high-power applications. Prepreg and core contribute to the thermal management of PCBs in different ways.

Thermal Conductivity

Core materials with higher thermal conductivity, such as metal-core laminates, help dissipate heat away from the components and prevent localized hot spots on the PCB. This improves the overall thermal performance and reliability of the board.

Thermal Expansion

Prepreg and core materials with similar coefficients of thermal expansion (CTE) are chosen to minimize stress and warpage caused by temperature fluctuations. Matched CTEs prevent delamination and ensure the long-term reliability of the PCB.

Challenges and Considerations in Prepreg and Core Selection

Selecting the appropriate prepreg and core materials for a specific PCB application involves considering various factors and overcoming certain challenges.

Material Compatibility

Ensuring compatibility between prepreg and core materials is crucial for the successful manufacturing of PCBs. Mismatched materials can lead to delamination, warpage, and other reliability issues. PCB designers must carefully select materials with compatible thermal, mechanical, and electrical properties.

Signal Integrity and High-Frequency Performance

As the demand for high-speed and high-frequency PCBs grows, maintaining signal integrity becomes increasingly challenging. Prepreg and core materials with low dielectric constant and dissipation factor are essential for minimizing signal loss and distortion. Additionally, designers must consider the skin effect and choose materials with appropriate surface roughness to optimize high-frequency performance.

Environmental Concerns and Regulations

With the increasing focus on environmental sustainability, PCB manufacturers are moving towards eco-friendly materials. Halogen-free prepreg and core materials are gaining popularity due to their reduced environmental impact and compliance with global regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

Future Trends and Innovations

As the electronics industry continues to evolve, prepreg and core materials are also undergoing advancements to meet the ever-growing demands of PCB manufacturing.

Advanced Materials

Researchers and material suppliers are developing advanced prepreg and core materials with improved properties, such as:

- Ultra-low loss materials for high-frequency applications

- High-temperature materials for harsh environments

- Flexible and stretchable materials for wearable electronics

- Biodegradable and recyclable materials for sustainability

3D Printing and Additive Manufacturing

3D printing and additive manufacturing technologies are emerging as potential alternatives to traditional PCB manufacturing methods. These technologies enable the creation of complex geometries and embedded components, opening up new possibilities for PCB design and functionality.

Integration of Embedded Components

The integration of embedded components, such as capacitors and resistors, within the PCB substrate is gaining traction. This approach offers several benefits, including reduced board size, improved signal integrity, and enhanced reliability. Prepreg and core materials play a vital role in accommodating embedded components and ensuring their proper functioning.

Frequently Asked Questions (FAQ)

-

What is the difference between prepreg and core in PCBs?

Prepreg is a composite material consisting of a reinforcement fabric impregnated with a partially cured thermoset resin, while core is a fully cured laminate that serves as the rigid foundation of the PCB. Prepreg acts as an adhesive and insulator between layers, while core provides mechanical stability and dimensional accuracy. -

How do prepreg and core affect the signal integrity in PCBs?

The dielectric properties of prepreg and core, such as dielectric constant (Dk) and dissipation factor (Df), influence signal propagation and integrity in PCBs. Low Dk and Df materials are preferred for high-frequency applications to minimize signal loss and distortion. Carefully selecting the thickness and dielectric properties of prepreg and core enables controlled impedance and maintains signal integrity. -

What are the environmental considerations when choosing prepreg and core materials?

With the increasing focus on environmental sustainability, PCB manufacturers are moving towards eco-friendly materials. Halogen-free prepreg and core materials are gaining popularity due to their reduced environmental impact and compliance with global regulations such as RoHS and REACH. -

How do prepreg and core contribute to thermal management in PCBs?

Core materials with higher thermal conductivity, such as metal-core laminates, help dissipate heat away from the components and prevent localized hot spots on the PCB. Prepreg and core materials with similar coefficients of thermal expansion (CTE) are chosen to minimize stress and warpage caused by temperature fluctuations, preventing delamination and ensuring long-term reliability. -

What are some future trends and innovations in prepreg and core materials?

Researchers and material suppliers are developing advanced prepreg and core materials with improved properties, such as ultra-low loss materials for high-frequency applications, high-temperature materials for harsh environments, flexible and stretchable materials for wearable electronics, and biodegradable and recyclable materials for sustainability. Additionally, 3D printing and additive manufacturing technologies are emerging as potential alternatives to traditional PCB manufacturing methods, enabling the creation of complex geometries and embedded components.

Conclusion

Prepreg and core are indispensable materials in the world of PCB manufacturing. They play critical roles in the construction, performance, and reliability of PCBs. Prepreg acts as an adhesive and insulator between layers, while core provides a rigid foundation and maintains dimensional accuracy. The properties and selection of prepreg and core materials significantly impact signal integrity, thermal management, and environmental sustainability.

As the electronics industry continues to advance, prepreg and core materials are evolving to meet the ever-growing demands of PCB manufacturing. Advanced materials, 3D printing, and the integration of embedded components are just a few examples of the future trends and innovations in this field.

By understanding the roles and importance of prepreg and core in PCB manufacturing, designers and engineers can make informed decisions when selecting materials and optimizing PCB designs. This knowledge is essential for creating high-performance, reliable, and sustainable PCBs that power the electronic devices and systems of today and tomorrow.

Leave a Reply