Introduction to PCB Quality

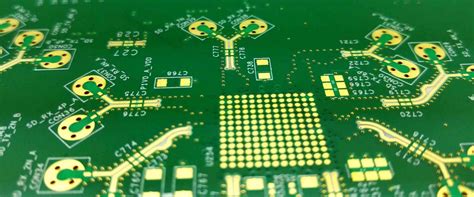

Printed Circuit Boards (PCBs) are the backbone of modern electronics, connecting and supporting various components to enable the functionality of devices we use every day. The quality of these PCBs is crucial for ensuring the reliability, performance, and longevity of the end products. In the competitive world of electronics manufacturing, maintaining high standards of PCB quality is not only a matter of customer satisfaction but also a key factor in building a strong reputation and securing long-term success.

This article delves into the various methods employed for final quality control in PCB manufacturing. We will explore the importance of rigorous testing and inspection procedures, the different stages of quality control, and the cutting-edge technologies and techniques used to guarantee the highest level of PCB quality. By understanding and implementing these methods, manufacturers can minimize defects, reduce costs associated with rework and replacements, and ultimately deliver products that meet or exceed customer expectations.

The Importance of Final Quality Control in PCB Manufacturing

Final quality control is a critical step in the PCB manufacturing process, as it serves as the last line of defense against potential defects and ensures that only products meeting the specified requirements make their way to the customers. The significance of final quality control can be understood through the following points:

-

Detecting and Eliminating Defects: Thorough inspection and testing during the final quality control stage help identify any defects that may have been introduced during the manufacturing process. By catching these issues before the PCBs are shipped, manufacturers can prevent defective products from reaching customers, thus avoiding costly recalls and damage to their reputation.

-

Ensuring Functionality and Reliability: Final quality control verifies that the manufactured PCBs function as intended and meet the specified performance criteria. This step is crucial for guaranteeing the reliability of the end products, as even minor defects can lead to malfunctions or premature failures in the field.

-

Maintaining Customer Satisfaction: Delivering high-quality PCBs consistently is essential for building and maintaining customer trust and satisfaction. By implementing robust final quality control measures, manufacturers can demonstrate their commitment to quality and provide customers with the assurance that they are receiving products that meet their requirements and expectations.

-

Reducing Costs: While investing in final quality control may seem like an additional expense, it can actually lead to significant cost savings in the long run. By identifying and addressing defects before the PCBs are shipped, manufacturers can avoid the expenses associated with rework, replacements, and warranty claims. Additionally, the improved quality and reliability of the products can lead to increased customer loyalty and repeat business.

-

Compliance with Industry Standards: Many industries have specific quality standards and regulations that PCBs must adhere to, such as IPC (Association Connecting Electronics Industries) standards. Final quality control helps ensure that the manufactured PCBs comply with these standards, thereby avoiding potential legal and financial consequences of non-compliance.

Stages of Final Quality Control in PCB Manufacturing

Final quality control in PCB manufacturing typically involves several stages, each focusing on different aspects of the PCB’s quality. These stages include:

1. Visual Inspection

The first stage of final quality control is visual inspection, where trained operators examine the PCBs for any visible defects or anomalies. This process can be performed manually, using magnifying lenses or microscopes, or with the help of automated optical inspection (AOI) systems. Some of the common defects that can be identified through visual inspection include:

- Solder bridges or shorts

- Missing or misaligned components

- Incorrect component placement

- Damaged or lifted pads

- Contamination or foreign objects

Visual inspection is a quick and effective way to catch glaring defects and ensure that the PCBs meet the basic visual requirements.

2. Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a more advanced form of visual inspection that utilizes high-resolution cameras and sophisticated image processing algorithms to detect defects on the PCBs. AOI systems can scan the entire surface of the PCB at high speeds, comparing the captured images to a pre-defined set of criteria or a “golden sample” to identify any discrepancies.

AOI offers several advantages over manual visual inspection:

- Higher accuracy and consistency in defect detection

- Faster inspection speeds, enabling higher throughput

- Ability to detect subtle defects that may be missed by human operators

- Automated documentation and data collection for traceability and process improvement

While AOI is highly effective, it may not be able to detect all types of defects, particularly those related to electrical functionality. Therefore, AOI is often used in combination with other testing methods to ensure comprehensive quality control.

3. X-Ray Inspection

X-ray inspection is a non-destructive testing method that allows manufacturers to examine the internal structure of the PCBs, including solder joints, vias, and other hidden features. This technique is particularly useful for inspecting high-density, multi-layer PCBs where defects may not be visible from the surface.

X-ray inspection systems use either 2D or 3D imaging technology to create detailed images of the PCB’s internal structure. These images can reveal defects such as:

- Voids or gaps in solder joints

- Insufficient or excessive solder

- Misaligned or shifted components

- Broken or damaged vias

- Shorts or opens in the internal layers

By detecting these internal defects, X-ray inspection helps ensure the structural integrity and reliability of the PCBs.

4. In-Circuit Testing (ICT)

In-Circuit Testing (ICT) is a comprehensive testing method that verifies the electrical functionality of the PCB by directly probing the individual components and circuits. ICT systems use a bed-of-nails fixture, which consists of an array of spring-loaded probes that make contact with the test points on the PCB.

During the ICT process, the system applies electrical stimuli to the PCB and measures the responses, comparing them to the expected values based on the design specifications. This allows the detection of a wide range of defects, such as:

- Incorrect component values or tolerances

- Shorts or opens in the circuits

- Missing or incorrectly placed components

- Defective or damaged components

ICT is highly effective in identifying functional defects that may not be detectable through visual or X-ray inspection. However, designing the test fixture and programming the test sequences can be time-consuming and costly, especially for complex PCBs with high component densities.

5. Functional Testing

Functional testing is the final stage of quality control, where the PCBs are tested under real-world operating conditions to ensure that they perform as intended. This stage involves powering up the PCBs and running a series of tests that simulate the actual application scenarios.

Functional testing can include:

- Power-on tests to verify proper power supply and voltage levels

- Communication tests to check the functionality of interfaces and protocols

- Signal integrity tests to ensure the quality of high-speed signals

- Environmental tests to validate the PCB’s performance under various temperature, humidity, and vibration conditions

Functional testing is crucial for catching any remaining defects or performance issues that may have escaped the previous testing stages. It also helps validate the PCB’s compatibility with the target system or device, ensuring smooth integration and operation.

Advanced Technologies and Techniques for PCB Quality Control

In addition to the standard testing and inspection methods, manufacturers are continuously adopting advanced technologies and techniques to enhance the efficiency and effectiveness of final quality control in PCB manufacturing. Some of these advancements include:

1. Automated 3D Solder Paste Inspection (SPI)

Automated 3D Solder Paste Inspection (SPI) is a technique used to evaluate the quality of solder paste deposition before the components are placed on the PCB. SPI systems use 3D imaging technology to measure the volume, height, and shape of the solder paste deposits, comparing them to the specified tolerances.

By detecting solder paste defects early in the process, SPI helps prevent issues such as insufficient or excessive solder, bridging, or poor wetting, which can lead to component failures or reliability problems. SPI also provides valuable data for process optimization, allowing manufacturers to fine-tune their solder paste printing parameters for improved quality and consistency.

2. Flying Probe Testing

Flying Probe Testing is an alternative to the traditional bed-of-nails fixture used in ICT. Instead of using a fixed array of probes, flying probe testers employ a set of movable probes that can access any point on the PCB surface. These probes are guided by a high-precision positioning system and can perform electrical tests on the PCB’s components and circuits.

The main advantages of flying probe testing include:

- Flexibility: The movable probes can adapt to different PCB layouts and designs without requiring a custom test fixture.

- Cost-effectiveness: Flying probe testers eliminate the need for expensive bed-of-nails fixtures, making them a more economical option for low-volume or prototype PCBs.

- Improved test coverage: The probes can access areas that may be difficult or impossible to reach with a fixed fixture, enabling more comprehensive testing.

However, flying probe testing is generally slower than ICT, as the probes need to move between test points. It is also less suitable for high-volume production due to the longer test times.

3. Automated X-Ray Inspection (AXI)

Automated X-Ray Inspection (AXI) combines the benefits of X-ray imaging with the speed and precision of automated inspection systems. AXI systems use advanced algorithms to analyze the X-ray images of the PCBs, detecting and classifying defects based on pre-defined criteria.

AXI offers several advantages over manual X-ray inspection:

- Faster inspection speeds, enabling higher throughput

- Improved accuracy and consistency in defect detection

- Ability to inspect complex, high-density PCBs with ease

- Automated data collection and reporting for traceability and process improvement

AXI is particularly useful for inspecting solder joints, vias, and other hidden features that are critical to the PCB’s reliability and performance.

4. Boundary Scan Testing

Boundary Scan Testing, also known as JTAG (Joint Test Action Group) testing, is a method for testing the interconnections and functionality of digital components on a PCB. This technique utilizes a built-in test infrastructure within the components, which allows the testing system to access and control the component’s inputs and outputs through a serial interface.

Boundary Scan Testing offers several benefits:

- Ability to test complex, high-density PCBs with limited physical access

- Detection of defects such as shorts, opens, and stuck-at faults in the interconnections between components

- Programming and verification of on-board firmware or configuration data

- Reduced test development time and cost compared to traditional functional testing methods

Boundary Scan Testing is particularly effective for testing PCBs with high-speed digital components, such as FPGAs, microprocessors, and memory devices.

5. Automated Functional Testing (AFT)

Automated Functional Testing (AFT) involves the use of robotic systems and software-driven test sequences to perform functional tests on the PCBs. AFT systems can simulate the real-world operating conditions and perform a wide range of tests, including power-on, communication, and signal integrity tests.

The main advantages of AFT include:

- Faster and more consistent testing compared to manual methods

- Ability to perform complex and repetitive test sequences with high accuracy

- Automated data collection and reporting for traceability and process improvement

- Reduced human error and variability in the testing process

AFT is especially valuable for high-volume production, where the speed and consistency of testing are critical for maintaining quality and meeting production targets.

Frequently Asked Questions (FAQ)

-

What is the difference between AOI and visual inspection?

Automated Optical Inspection (AOI) uses high-resolution cameras and image processing algorithms to detect defects on the PCBs, while visual inspection is performed manually by trained operators using magnifying lenses or microscopes. AOI is faster, more accurate, and more consistent than manual visual inspection, but it may not be able to detect all types of defects. -

How does X-ray inspection detect defects that are not visible from the surface?

X-ray inspection uses high-energy electromagnetic radiation to create images of the PCB’s internal structure, including solder joints, vias, and other hidden features. These images can reveal defects such as voids, insufficient or excessive solder, misaligned components, and shorts or opens in the internal layers, which may not be visible from the surface. -

What are the limitations of In-Circuit Testing (ICT)?

In-Circuit Testing (ICT) requires a custom bed-of-nails fixture, which can be expensive and time-consuming to design and manufacture, especially for complex, high-density PCBs. Additionally, ICT may not be able to detect all types of functional defects, particularly those related to the interaction between components or the overall system performance. -

What is the role of functional testing in final quality control?

Functional testing is the last stage of quality control, where the PCBs are tested under real-world operating conditions to ensure that they perform as intended. This stage helps catch any remaining defects or performance issues that may have escaped the previous testing stages and validates the PCB’s compatibility with the target system or device. -

How can advanced technologies and techniques improve PCB quality control?

Advanced technologies and techniques, such as Automated 3D Solder Paste Inspection (SPI), Flying Probe Testing, Automated X-Ray Inspection (AXI), Boundary Scan Testing, and Automated Functional Testing (AFT), can enhance the efficiency, accuracy, and effectiveness of final quality control in PCB manufacturing. These methods help detect a wider range of defects, reduce testing time and cost, and provide valuable data for process improvement and traceability.

Conclusion

Final quality control is a critical aspect of PCB manufacturing, ensuring that only products meeting the highest standards of quality and reliability are delivered to customers. By employing a combination of visual inspection, automated optical inspection, X-ray inspection, in-circuit testing, and functional testing, manufacturers can identify and eliminate defects at various stages of the production process.

Furthermore, the adoption of advanced technologies and techniques, such as 3D solder paste inspection, flying probe testing, automated X-ray inspection, boundary scan testing, and automated functional testing, can significantly enhance the efficiency and effectiveness of quality control procedures. These advancements enable manufacturers to detect a wider range of defects, reduce testing time and cost, and continuously improve their processes based on the collected data.

Investing in robust final quality control methods not only helps manufacturers deliver high-quality PCBs consistently but also leads to increased customer satisfaction, reduced costs associated with rework and replacements, and a stronger reputation in the competitive electronics industry. As the complexity and demands of modern electronics continue to grow, the importance of implementing comprehensive and advanced quality control measures in PCB manufacturing cannot be overstated.

By understanding and leveraging the various methods and technologies available for final quality control, PCB manufacturers can position themselves for success in the ever-evolving world of electronics, while ensuring that their products meet the highest standards of quality and reliability.

Leave a Reply