Introduction to Copper PCB Manufacturing in China

China has emerged as a global leader in the production of printed circuit boards (PCBs), with a significant focus on copper PCB manufacturing. The country’s vast manufacturing capabilities, coupled with its cost-effective labor and raw materials, have made it an attractive destination for electronics companies worldwide. In this article, we will delve into the world of copper PCB manufacturers in China, exploring their processes, advantages, and the factors that have contributed to their success.

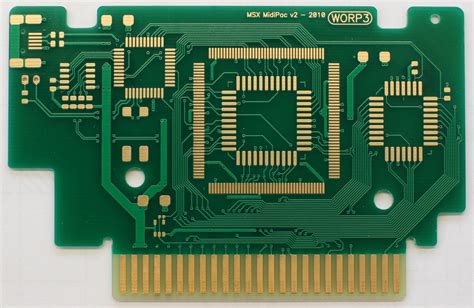

What are Copper PCBs?

Copper PCBs are printed circuit boards that utilize copper as the primary conductive material for the circuit traces and pads. Copper is an excellent choice for PCBs due to its high electrical conductivity, durability, and relatively low cost compared to other conductive materials. The use of copper in PCBs enables efficient transmission of electrical signals, heat dissipation, and overall reliability of the electronic device.

Advantages of Copper PCBs

Copper PCBs offer several advantages over other types of PCBs:

-

High Conductivity: Copper has excellent electrical conductivity, allowing for efficient transmission of signals and power throughout the circuit board.

-

Thermal Management: Copper’s thermal conductivity helps dissipate heat generated by electronic components, preventing overheating and ensuring stable performance.

-

Durability: Copper PCBs are known for their durability and resistance to corrosion, making them suitable for a wide range of applications and environments.

-

Cost-Effective: Compared to other conductive materials like gold or silver, copper is relatively inexpensive, making it an economical choice for PCB manufacturing.

The Rise of China’s Copper PCB Manufacturing Industry

China’s dominance in the copper PCB manufacturing industry can be attributed to several factors:

Low Labor Costs

One of the primary reasons for China’s success in PCB manufacturing is its low labor costs. The country’s vast workforce and competitive wages have allowed manufacturers to keep production costs down, enabling them to offer competitive prices to international clients.

Extensive Supply Chain

China has developed an extensive supply chain for PCB manufacturing, with numerous suppliers of raw materials, components, and equipment. This well-established ecosystem facilitates efficient production processes and helps manufacturers meet the growing demand for copper PCBs.

Government Support

The Chinese government has actively supported the growth of the electronics industry, including PCB manufacturing. Through favorable policies, infrastructure development, and financial incentives, the government has created an environment conducive to the expansion of copper PCB manufacturing.

Technological Advancements

Chinese copper PCB manufacturers have invested in advanced manufacturing technologies and processes to enhance product quality and efficiency. The adoption of automated equipment, high-precision machinery, and stringent quality control measures has enabled these manufacturers to meet the demanding requirements of global electronics companies.

Key Copper PCB Manufacturing Processes in China

The manufacturing of copper PCBs in China involves several critical processes:

PCB Design and Layout

The first step in copper PCB manufacturing is the design and layout of the circuit board. This process involves creating a detailed schematic of the electronic circuit and translating it into a physical layout that specifies the placement of components, traces, and vias.

Copper Clad Laminate Selection

The choice of copper clad laminate is crucial in determining the performance and reliability of the PCB. Chinese manufacturers offer a range of laminate options, including FR-4, high-Tg FR-4, and specialized materials for high-frequency or high-temperature applications.

Drilling and Plating

Once the laminate is selected, the PCB undergoes drilling to create holes for component leads and vias. The holes are then plated with copper to establish electrical connectivity between layers.

Patterning and Etching

The desired circuit pattern is transferred onto the copper layer using photoresist and exposure to UV light. The exposed areas are then etched away, leaving the desired copper traces and pads.

Solder Mask Application

A solder mask is applied to the PCB to protect the copper traces from oxidation and prevent solder bridges during component assembly. The solder mask also provides insulation and improves the aesthetics of the PCB.

Surface Finishing

The final step in copper PCB manufacturing is surface finishing, which involves applying a protective coating to the exposed copper areas. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Leading Copper PCB Manufacturers in China

China is home to numerous copper PCB manufacturers, ranging from large-scale enterprises to specialized small and medium-sized companies. Some of the leading players in the industry include:

-

Shenzhen JDB Technology Co., Ltd.: Specializing in high-density interconnect (HDI) and multilayer PCBs, Shenzhen JDB Technology has a strong presence in the consumer electronics and automotive industries.

-

Kingboard Laminates Holdings Limited: As one of the largest PCB manufacturers in China, Kingboard Laminates offers a wide range of copper PCB solutions, including single-sided, double-sided, and multilayer boards.

-

Unimicron Technology (SuZhou) Corp.: Unimicron is a global leader in PCB manufacturing, with a significant presence in China. The company focuses on advanced PCB technologies, such as HDI, flexible PCBs, and IC substrates.

-

Zhen Ding Technology Holding Limited: Zhen Ding Technology is a major supplier of copper PCBs for the telecommunications, computer, and consumer electronics industries. The company has multiple manufacturing facilities across China.

-

Shennan Circuits Co., Ltd.: Specializing in high-end copper PCBs, Shennan Circuits serves customers in the aerospace, defense, and medical industries, among others.

These are just a few examples of the many copper PCB manufacturers operating in China. The country’s diverse manufacturing landscape allows for a wide range of options to suit different customer requirements and budgets.

Quality Control and Certifications

To ensure the quality and reliability of copper PCBs manufactured in China, companies adhere to strict quality control measures and international standards. Many Chinese copper PCB manufacturers have obtained certifications such as:

- ISO 9001 (Quality Management System)

- ISO 14001 (Environmental Management System)

- IATF 16949 (Automotive Quality Management System)

- UL (Underwriters Laboratories) certification

- RoHS (Restriction of Hazardous Substances) compliance

These certifications demonstrate the commitment of Chinese manufacturers to producing high-quality copper PCBs that meet the requirements of global customers.

Challenges and Future Outlook

Despite the success of China’s copper PCB manufacturing industry, there are challenges that need to be addressed:

Environmental Concerns

The PCB manufacturing process involves the use of chemicals and generates waste that can have a negative impact on the environment. Chinese manufacturers are increasingly adopting eco-friendly practices and investing in waste treatment facilities to minimize their environmental footprint.

Intellectual Property Protection

Protecting intellectual property rights is a concern for companies outsourcing their PCB manufacturing to China. Manufacturers must implement strict measures to safeguard customer designs and confidential information.

Competition from Other Countries

As labor costs in China rise, some companies are exploring alternative manufacturing destinations, such as Vietnam and India. Chinese manufacturers must continue to innovate and improve their processes to maintain their competitive edge.

Despite these challenges, the future outlook for copper PCB manufacturing in China remains positive. The country’s well-established infrastructure, skilled workforce, and ongoing technological advancements position it to maintain its leadership in the global PCB industry.

Frequently Asked Questions (FAQ)

-

Q: What is the minimum order quantity (MOQ) for copper PCBs from Chinese manufacturers?

A: The MOQ varies among manufacturers, but typically ranges from 100 to 1,000 pieces, depending on the complexity and specifications of the PCB. -

Q: How long does it take to manufacture copper PCBs in China?

A: Lead times depend on factors such as the complexity of the design, order quantity, and manufacturer’s capacity. On average, production can take anywhere from 1 to 4 weeks, with additional time required for shipping. -

Q: Can Chinese copper PCB manufacturers provide assembly services?

A: Yes, many Chinese PCB manufacturers offer turnkey solutions that include PCB assembly. This can be beneficial for companies looking to streamline their supply chain and reduce overall costs. -

Q: How can I ensure the quality of copper PCBs manufactured in China?

A: When selecting a Chinese copper PCB manufacturer, look for companies with established quality control processes, international certifications, and a proven track record of delivering high-quality products. Conducting thorough due diligence and requesting samples before placing a large order can also help ensure quality. -

Q: What are the payment terms and shipping options for copper PCBs from China?

A: Payment terms vary among manufacturers but often include options such as wire transfer, letter of credit, or payment through online platforms like Alibaba or Global Sources. Shipping options include air freight, sea freight, and express courier services, depending on the urgency and size of the order.

Conclusion

China’s copper PCB manufacturing industry has grown significantly over the years, establishing the country as a global leader in PCB production. The combination of low labor costs, an extensive supply chain, government support, and technological advancements has enabled Chinese manufacturers to meet the growing demand for high-quality copper PCBs.

As the electronics industry continues to evolve, Chinese copper PCB manufacturers are well-positioned to adapt and innovate, offering a wide range of solutions to meet the diverse needs of international customers. While challenges such as environmental concerns and competition from other countries persist, China’s commitment to quality, efficiency, and technological advancement is likely to maintain its dominant position in the global PCB market.

For companies seeking reliable and cost-effective copper PCB manufacturing solutions, China offers a compelling value proposition. By partnering with experienced and reputable Chinese manufacturers, businesses can leverage the country’s extensive capabilities and expertise to bring their electronic products to market quickly and efficiently.

Leave a Reply