Introduction to PCB Assembly Drawings

PCB assembly drawings are essential documents that provide crucial information for the manufacturing and assembly of printed circuit boards (PCBs). These drawings contain detailed instructions, component placement, and other specifications necessary for the accurate and efficient assembly of the PCB. In this article, we will explore the key elements of PCB assembly drawings and discuss techniques for creating them quickly and efficiently.

What is a PCB Assembly Drawing?

A PCB assembly drawing, also known as a PCB assembly diagram or PCB assembly documentation, is a visual representation of the PCB that includes all the information required for the assembly process. It typically consists of the following elements:

- Board outline and dimensions

- Component placement and orientation

- Reference designators for components

- Bill of Materials (BOM)

- Assembly notes and instructions

Importance of Precise PCB Assembly Drawings

Precise PCB assembly drawings are crucial for several reasons:

- They ensure the correct placement and orientation of components on the PCB.

- They help avoid assembly errors, which can lead to costly rework or scrapped boards.

- They facilitate efficient communication between the design team and the manufacturing team.

- They serve as a reference for quality control and inspection during the assembly process.

Key Elements of a PCB Assembly Drawing

To create a comprehensive and precise PCB assembly drawing, it is essential to include the following key elements:

Board Outline and Dimensions

The board outline and dimensions provide the physical characteristics of the PCB. This information includes:

- Board size (length, width, and thickness)

- Mounting hole locations and sizes

- Cutouts and special features

- Layer stackup information

Component Placement and Orientation

Component placement and orientation are critical aspects of a PCB assembly drawing. This section should include:

- Exact locations of components on the board

- Orientation of components (e.g., pin 1 location, polarity)

- Footprint information for each component

- Clearance requirements between components

Reference Designators

Reference designators are unique identifiers assigned to each component on the PCB. They help in identifying components during the assembly process and troubleshooting. Reference designators should follow a consistent naming convention, such as:

- R for resistors (e.g., R1, R2)

- C for capacitors (e.g., C1, C2)

- U for integrated circuits (e.g., U1, U2)

- D for diodes (e.g., D1, D2)

Bill of Materials (BOM)

The Bill of Materials (BOM) is a list of all the components required for the assembly of the PCB. It should include the following information for each component:

- Reference designator

- Manufacturer part number

- Description

- Quantity

- Package type

Here’s an example of a BOM table:

| Reference | Manufacturer Part Number | Description | Quantity | Package |

|---|---|---|---|---|

| R1, R2 | ABC123 | 10kΩ Resistor | 2 | 0805 |

| C1 | XYZ456 | 1μF Capacitor | 1 | 0603 |

| U1 | IC1234 | Microcontroller | 1 | TQFP-48 |

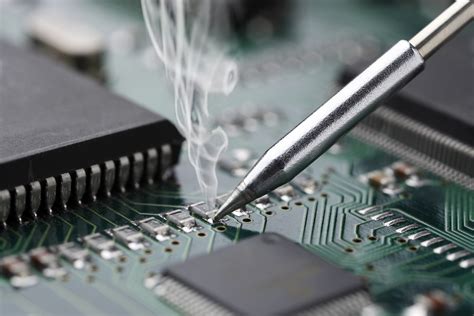

Assembly Notes and Instructions

Assembly notes and instructions provide additional guidance for the assembly process. This may include:

- Specific assembly techniques or requirements

- Soldering instructions

- Inspection and testing guidelines

- Handling precautions for sensitive components

Techniques for Creating PCB Assembly Drawings Efficiently

Creating precise PCB assembly drawings can be time-consuming, but there are several techniques to streamline the process and improve efficiency:

Use PCB Design Software

Modern PCB design software, such as Altium Designer, Eagle, or KiCad, offers powerful tools for creating PCB assembly drawings. These software packages allow you to:

- Import the PCB design files

- Automatically generate component placement and reference designators

- Create a BOM based on the components used in the design

- Add assembly notes and instructions

Leverage Templates and Libraries

Developing templates and component libraries can significantly speed up the creation of PCB assembly drawings. Templates ensure consistency across projects and reduce the time spent on formatting and layout. Component libraries store frequently used components, along with their footprints and other relevant information, making it easier to place them on the drawing.

Collaborate with the Manufacturing Team

Collaborating closely with the manufacturing team can help identify potential issues early in the design process and ensure that the PCB assembly drawing meets their requirements. This collaboration can involve:

- Reviewing the drawing with the manufacturing team for feedback and suggestions

- Discussing assembly techniques and requirements specific to their processes

- Ensuring that the drawing follows their preferred format and conventions

Automate Repetitive Tasks

Automating repetitive tasks, such as generating reference designators or updating the BOM, can save significant time and reduce the risk of errors. Many PCB design software packages offer scripting capabilities or integration with external tools to automate these tasks.

Best Practices for PCB Assembly Drawings

To ensure the quality and effectiveness of your PCB assembly drawings, consider the following best practices:

Use Clear and Consistent Formatting

Consistent formatting makes the drawing easier to read and understand. This includes:

- Using a clear and legible font

- Maintaining consistent line weights and styles

- Grouping related information together

- Using appropriate symbols and colors

Provide Accurate and Complete Information

Accurate and complete information is essential for a successful PCB assembly. Double-check the following:

- Component placement and orientation

- Reference designators

- BOM entries

- Assembly notes and instructions

Include Revision Control

Implementing revision control helps track changes to the PCB assembly drawing over time. This involves:

- Assigning a unique revision number to each version of the drawing

- Including a revision history table with dates, descriptions, and approvers

- Clearly marking the current revision on the drawing

Communicate Effectively with Stakeholders

Effective communication with stakeholders, such as the design team, manufacturing team, and project managers, is crucial for the success of the PCB assembly process. This includes:

- Providing regular updates on the status of the drawing

- Responding promptly to questions and feedback

- Collaborating to resolve any issues or concerns

Frequently Asked Questions (FAQ)

-

What is the difference between a PCB assembly drawing and a schematic?

A PCB assembly drawing focuses on the physical placement and orientation of components on the PCB, while a schematic represents the electrical connections between components. -

How detailed should a PCB assembly drawing be?

A PCB assembly drawing should be detailed enough to ensure accurate and efficient assembly of the PCB. It should include all the necessary information, such as component placement, reference designators, and assembly notes, without being overly cluttered or complex. -

Can I use the same PCB assembly drawing for different PCB manufacturers?

While the core information in a PCB assembly drawing remains the same, it’s essential to collaborate with each manufacturer to ensure that the drawing meets their specific requirements and preferences. -

How often should I update my PCB assembly drawing?

Update your PCB assembly drawing whenever there are changes to the PCB design, components, or assembly process. Be sure to communicate these updates to all relevant stakeholders and maintain proper revision control. -

What file formats are commonly used for PCB assembly drawings?

Common file formats for PCB assembly drawings include PDF, DXF, and Gerber. Consult with your PCB manufacturer to determine their preferred file format.

Conclusion

Creating precise PCB assembly drawings is essential for the accurate and efficient manufacturing of printed circuit boards. By including key elements such as board outline and dimensions, component placement and orientation, reference designators, BOM, and assembly notes, you can ensure that your PCB assembly drawing provides all the necessary information for a successful assembly process.

To create PCB assembly drawings quickly and efficiently, leverage the power of PCB design software, develop templates and libraries, collaborate with the manufacturing team, and automate repetitive tasks. By following best practices such as using clear and consistent formatting, providing accurate and complete information, implementing revision control, and communicating effectively with stakeholders, you can further enhance the quality and effectiveness of your PCB assembly drawings.

By investing time and effort into creating precise and efficient PCB assembly drawings, you can streamline the manufacturing process, reduce the risk of errors, and ultimately deliver high-quality PCBs that meet the requirements of your project.

Leave a Reply