What is an Aluminum PCB?

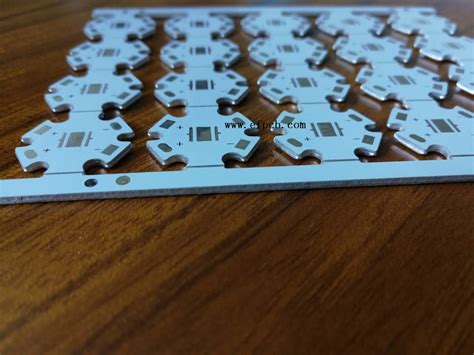

An Aluminum PCB, also known as a Metal Core PCB (MCPCB), is a type of printed circuit board that utilizes an aluminum substrate instead of the traditional FR-4 material. The aluminum substrate serves as a heat sink, allowing for efficient heat dissipation from the components mounted on the PCB. This makes Aluminum PCBs ideal for applications that generate significant amounts of heat, such as high-power LEDs, power electronics, and automotive systems.

The structure of an Aluminum PCB typically consists of the following layers:

- Dielectric layer

- Copper circuit layer

- Thermal insulation layer

- Aluminum substrate

Advantages of Aluminum PCBs

Aluminum PCBs offer several advantages over traditional FR-4 PCBs:

- Enhanced thermal management

- Improved mechanical stability

- Reduced weight and thickness

- Increased durability and reliability

- Better electromagnetic shielding

Applications of Aluminum PCBs

High-Power LED Lighting

Aluminum PCBs are widely used in high-power LED lighting applications due to their excellent thermal management capabilities. LEDs generate a significant amount of heat, which can negatively impact their performance and lifespan if not properly dissipated. By using an Aluminum PCB, the heat generated by the LEDs can be efficiently transferred to the aluminum substrate and dissipated into the surrounding environment.

Power Electronics

Power electronics, such as motor drives, inverters, and power supplies, also benefit from the use of Aluminum PCBs. These applications often involve high currents and voltages, which can generate substantial heat. The aluminum substrate in an Aluminum PCB helps to distribute and dissipate this heat, ensuring the reliable operation of the power electronics components.

Automotive Electronics

Aluminum PCBs are increasingly being used in automotive electronics, particularly in electric and hybrid vehicles. These vehicles rely heavily on power electronics for functions such as battery management, motor control, and charging systems. The use of Aluminum PCBs in these applications helps to ensure reliable operation in the harsh automotive environment, where temperatures can vary widely and vibrations are common.

Designing Aluminum PCBs

Designing an Aluminum PCB requires careful consideration of several factors:

- Thermal management

- Dielectric material selection

- Copper thickness and trace width

- Mechanical constraints

- Manufacturing process

Thermal Management

Thermal management is a critical aspect of Aluminum PCB design. The designer must ensure that the heat generated by the components can be efficiently transferred to the aluminum substrate and dissipated into the surrounding environment. This involves selecting the appropriate dielectric material, copper thickness, and trace width to minimize thermal resistance.

Dielectric Material Selection

The dielectric material used in an Aluminum PCB must have good thermal conductivity and electrical insulation properties. Some common dielectric materials used in Aluminum PCBs include:

- Alumina (Al2O3)

- Aluminum Nitride (AlN)

- Boron Nitride (BN)

- Silicon Nitride (Si3N4)

The choice of dielectric material depends on the specific application requirements, such as the operating temperature range, dielectric strength, and thermal conductivity.

Copper Thickness and Trace Width

The copper thickness and trace width in an Aluminum PCB must be carefully selected to ensure optimal electrical and thermal performance. Thicker copper layers can improve current carrying capacity and thermal conductivity, but they also increase the overall thickness and weight of the PCB. Wider traces can also improve current carrying capacity and reduce resistance, but they may impact the PCB layout and routing.

Mechanical Constraints

Aluminum PCBs have different mechanical properties compared to traditional FR-4 PCBs. The designer must consider factors such as the coefficient of thermal expansion (CTE) mismatch between the aluminum substrate and the copper layer, as well as the overall stiffness and rigidity of the PCB. Proper mechanical design can help to minimize stress and strain on the components and ensure reliable operation over the PCB’s lifetime.

Manufacturing Process

The manufacturing process for Aluminum PCBs is slightly different from that of traditional FR-4 PCBs. The aluminum substrate must be properly prepared and cleaned before the dielectric layer and copper layer can be applied. The choice of manufacturing process, such as adhesive lamination or direct bonding, can impact the thermal and mechanical properties of the final PCB.

Aluminum PCB Material Properties

| Material | Thermal Conductivity (W/mK) | Dielectric Constant | Dielectric Strength (kV/mm) |

|---|---|---|---|

| Alumina | 20-30 | 9.0-10.0 | 10-20 |

| Aluminum Nitride | 140-180 | 8.0-9.0 | 14-18 |

| Boron Nitride | 30-100 | 4.0-5.0 | 40-50 |

| Silicon Nitride | 60-90 | 7.0-8.0 | 20-30 |

Frequently Asked Questions (FAQ)

1. What is the difference between an Aluminum PCB and a traditional FR-4 PCB?

An Aluminum PCB uses an aluminum substrate instead of the FR-4 material used in traditional PCBs. The aluminum substrate serves as a heat sink, allowing for better thermal management and heat dissipation. Aluminum PCBs also offer improved mechanical stability, reduced weight and thickness, and better electromagnetic shielding compared to FR-4 PCBs.

2. What are the main applications of Aluminum PCBs?

Aluminum PCBs are commonly used in applications that generate significant amounts of heat, such as high-power LED lighting, power electronics, and automotive electronics. They are particularly useful in applications where efficient heat dissipation and reliable operation in harsh environments are critical.

3. What factors should be considered when designing an Aluminum PCB?

When designing an Aluminum PCB, several factors must be considered, including thermal management, dielectric material selection, copper thickness and trace width, mechanical constraints, and the manufacturing process. Proper consideration of these factors can help to ensure optimal electrical and thermal performance, as well as reliable operation over the PCB’s lifetime.

4. How does the manufacturing process for Aluminum PCBs differ from traditional FR-4 PCBs?

The manufacturing process for Aluminum PCBs involves preparing and cleaning the aluminum substrate before applying the dielectric layer and copper layer. The choice of manufacturing process, such as adhesive lamination or direct bonding, can impact the thermal and mechanical properties of the final PCB. In contrast, traditional FR-4 PCBs do not require the same substrate preparation and bonding processes.

5. What are some common dielectric materials used in Aluminum PCBs?

Common dielectric materials used in Aluminum PCBs include Alumina (Al2O3), Aluminum Nitride (AlN), Boron Nitride (BN), and Silicon Nitride (Si3N4). The choice of dielectric material depends on the specific application requirements, such as the operating temperature range, dielectric strength, and thermal conductivity.

Conclusion

Aluminum PCBs offer a unique combination of thermal management, mechanical stability, and electrical performance, making them an attractive option for a wide range of applications. By understanding the key characteristics and design considerations of Aluminum PCBs, engineers and designers can leverage their benefits to create more efficient, reliable, and high-performance electronic systems. As the demand for high-power and thermally challenging applications continues to grow, the use of Aluminum PCBs is likely to expand across various industries, driving innovation and advancement in the field of printed circuit board technology.

Leave a Reply