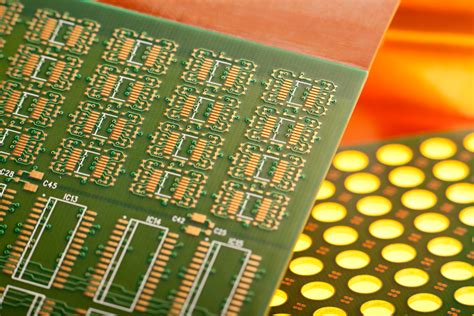

What is a Rigid PCB?

A rigid PCB is a printed circuit board that is made from a solid, non-flexible substrate material, typically FR-4 glass epoxy. The board is composed of multiple layers of copper foil laminated together with the substrate, forming a rigid and sturdy structure. Rigid PCBs are the most common type of PCBs used in electronic devices.

Characteristics of Rigid PCBs

- Rigid and non-flexible structure

- High dimensional stability

- Excellent mechanical strength

- Good thermal conductivity

- Suitable for high-density component placement

Applications of Rigid PCBs

Rigid PCBs find applications in a wide range of electronic devices and systems, including:

- Consumer electronics (smartphones, laptops, televisions)

- Industrial equipment (automation systems, control panels)

- Medical devices (diagnostic equipment, patient monitors)

- Automotive electronics (engine control units, infotainment systems)

- Aerospace and defense systems (avionics, radar systems)

What is a Flexible PCB?

A flexible PCB, also known as a flex circuit, is a printed circuit board that is made from a flexible substrate material, such as polyimide or polyester. The copper traces are bonded to the flexible substrate, allowing the PCB to bend, fold, and conform to various shapes. Flexible PCBs are ideal for applications where space is limited, or where the PCB needs to fit into a specific form factor.

Characteristics of Flexible PCBs

- Flexible and conformable structure

- Lightweight and thin

- High resistance to vibration and shock

- Excellent thermal stability

- Reduced assembly time and costs

Applications of Flexible PCBs

Flexible PCBs are commonly used in applications that require flexibility, compact packaging, or high reliability, such as:

- Wearable devices (smartwatches, fitness trackers)

- Medical implants (pacemakers, hearing aids)

- Aerospace and military equipment (missiles, satellites)

- Automotive electronics (steering wheel controls, seat heaters)

- Consumer electronics (camera modules, display interconnects)

Key Differences between Rigid PCB and Flexible PCB

| Aspect | Rigid PCB | Flexible PCB |

|---|---|---|

| Substrate Material | FR-4 glass epoxy | Polyimide or polyester |

| Flexibility | Non-flexible, rigid structure | Flexible, conformable structure |

| Thickness | Typically 0.8mm to 3.2mm | Typically 0.1mm to 0.3mm |

| Weight | Heavier compared to flexible PCBs | Lightweight |

| Mechanical Strength | High | Lower than rigid PCBs |

| Thermal Conductivity | Good | Lower than rigid PCBs |

| Component Density | High | Lower than rigid PCBs |

| Assembly | Requires through-hole or surface-mount technology | Can use adhesive bonding or ZIF connectors |

| Cost | Lower cost for high-volume production | Higher cost due to specialized materials and processes |

Substrate Material and Flexibility

The most significant difference between rigid PCBs and flexible PCBs lies in their substrate materials and flexibility. Rigid PCBs use a solid, non-flexible substrate like FR-4 glass epoxy, which provides excellent mechanical strength and dimensional stability. On the other hand, flexible PCBs employ flexible substrates such as polyimide or polyester, allowing them to bend and conform to various shapes.

Thickness and Weight

Rigid PCBs are typically thicker than flexible PCBs, with a standard thickness range of 0.8mm to 3.2mm. This thickness contributes to their rigidity and mechanical strength. In contrast, flexible PCBs are much thinner, usually ranging from 0.1mm to 0.3mm, making them lightweight and ideal for applications where space and weight are critical factors.

Mechanical Strength and Thermal Conductivity

Due to their solid substrate and thicker profile, rigid PCBs offer higher mechanical strength compared to flexible PCBs. They can withstand greater physical stress and provide better support for heavy components. Additionally, rigid PCBs have good thermal conductivity, allowing for efficient heat dissipation from electronic components.

Flexible PCBs, while not as mechanically strong as rigid PCBs, offer superior resistance to vibration and shock. Their flexible nature allows them to absorb and dissipate mechanical stresses more effectively. However, their thermal conductivity is lower than that of rigid PCBs, which can be a consideration in applications with high heat generation.

Component Density and Assembly

Rigid PCBs are well-suited for high-density component placement, as they provide a stable and flat surface for mounting components using through-hole or surface-mount technology. The rigidity of the board ensures accurate positioning and soldering of components.

Flexible PCBs, due to their thinner profile and flexible nature, may have limitations in terms of component density. However, they offer unique assembly options, such as adhesive bonding or the use of zero insertion force (ZIF) connectors, which can simplify the assembly process and reduce costs.

Cost Considerations

The cost of rigid PCBs is generally lower compared to flexible PCBs, particularly for high-volume production. The manufacturing process for rigid PCBs is well-established, and the materials used are readily available and cost-effective.

Flexible PCBs, on the other hand, require specialized materials and manufacturing processes, which can increase their cost. The use of flexible substrates, such as polyimide, and the need for additional processing steps like cover lay application and stiffener attachment contribute to the higher cost of flexible PCBs.

Combining Rigid and Flexible PCBs

In some cases, the best solution may be a combination of rigid and flexible PCBs, known as rigid-flex PCBs. Rigid-flex PCBs incorporate both rigid and flexible sections on a single board, allowing for the benefits of both technologies.

Rigid-flex PCBs offer several advantages:

- Reduced assembly time and costs by eliminating the need for separate connectors

- Improved signal integrity and reliability by minimizing interconnections

- Enhanced design flexibility by allowing for 3D packaging and unique form factors

- Reduced overall system size and weight

Rigid-flex PCBs find applications in various industries, including:

- Aerospace and defense (avionics, satellite systems)

- Medical devices (portable medical equipment, implantable devices)

- Automotive electronics (control modules, sensors)

- Consumer electronics (foldable smartphones, VR/AR headsets)

FAQ

1. Can flexible PCBs replace rigid PCBs in all applications?

No, flexible PCBs cannot replace rigid PCBs in all applications. While flexible PCBs offer unique advantages in terms of flexibility and conformability, they may not be suitable for applications that require high mechanical strength, thermal conductivity, or high-density component placement. The choice between rigid and flexible PCBs depends on the specific requirements of the application.

2. Are flexible PCBs more expensive than rigid PCBs?

Yes, flexible PCBs are generally more expensive than rigid PCBs. The higher cost is attributed to the specialized materials, such as polyimide substrates, and additional manufacturing processes required for flexible PCBs. However, the cost difference may be justified in applications where the unique properties of flexible PCBs, such as flexibility and lightweight, are essential.

3. Can rigid PCBs be bent or flexed?

No, rigid PCBs are not designed to be bent or flexed. The rigid substrate material, typically FR-4 glass epoxy, does not allow for significant flexing without risking damage to the board or the components. If an application requires a PCB to bend or conform to a specific shape, a flexible PCB or a rigid-flex PCB should be considered.

4. What is the typical lifespan of a flexible PCB compared to a rigid PCB?

The lifespan of a flexible PCB can be comparable to or even longer than that of a rigid PCB, depending on the application and operating conditions. Flexible PCBs are highly resistant to vibration and shock, which can contribute to their longevity in applications subject to mechanical stresses. However, factors such as temperature, humidity, and the quality of the manufacturing process can impact the lifespan of both rigid and flexible PCBs.

5. Can flexible PCBs be used in high-temperature applications?

Yes, flexible PCBs can be used in high-temperature applications, but the choice of substrate material is crucial. Polyimide, a commonly used substrate for flexible PCBs, has excellent thermal stability and can withstand temperatures up to 200°C or higher. However, for extreme high-temperature applications, specialized substrate materials like polytetrafluoroethylene (PTFE) or liquid crystal polymer (LCP) may be required.

Conclusion

In conclusion, rigid PCBs and flexible PCBs each have their own unique characteristics, advantages, and applications. Rigid PCBs offer high mechanical strength, good thermal conductivity, and are suitable for high-density component placement. Flexible PCBs, on the other hand, provide flexibility, lightweight, and high resistance to vibration and shock.

The choice between rigid and flexible PCBs depends on the specific requirements of the application, such as space constraints, environmental conditions, and mechanical demands. In some cases, a combination of rigid and flexible sections in the form of rigid-flex PCBs can offer the best of both worlds.

Understanding the differences between rigid PCBs and flexible PCBs is essential for designers and engineers to make informed decisions when selecting the appropriate type of PCB for their projects. By considering factors such as substrate material, flexibility, thickness, weight, mechanical strength, thermal conductivity, component density, assembly options, and cost, they can choose the PCB technology that best suits their needs and ensures optimal performance and reliability.

Leave a Reply