The Dangers of Conventional PCB Manufacturing

Health Risks Associated with Hazardous Chemicals

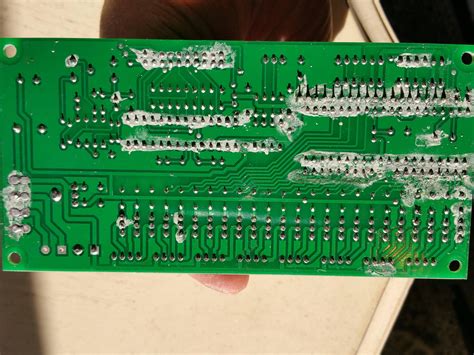

Conventional PCB manufacturing processes involve the use of various hazardous chemicals, such as:

- Lead

- Mercury

- Cadmium

- Beryllium

- Hexavalent Chromium

These chemicals can pose serious health risks to workers involved in the manufacturing process, as well as to the end-users of the electronic devices. Exposure to these substances can lead to a range of health problems, including:

- Respiratory issues

- Skin irritation and allergies

- Neurological disorders

- Cancer

- Reproductive health problems

Environmental Impact of Chemical-Based PCB Manufacturing

In addition to the health risks, chemical-based PCB manufacturing also has a significant environmental impact. The hazardous chemicals used in the process can lead to:

- Air pollution

- Water contamination

- Soil degradation

- Ecosystem disruption

The improper disposal of these chemicals can have long-lasting effects on the environment, harming wildlife and contaminating natural resources.

The Rise of Chemical-Free PCB Manufacturing

To address the concerns associated with conventional PCB manufacturing, the industry has been shifting towards chemical-free alternatives. Chemical-free PCB fabrication and assembly aim to minimize the use of hazardous substances while maintaining the quality and reliability of the end product.

Green PCB Initiatives

Several initiatives have been undertaken to promote the adoption of chemical-free PCB manufacturing, such as:

- Restriction of Hazardous Substances (RoHS) Directive

- Waste Electrical and Electronic Equipment (WEEE) Directive

- Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) Regulation

These initiatives set guidelines and restrictions on the use of hazardous substances in electronic products, encouraging manufacturers to adopt environmentally friendly practices.

Alternative Materials and Processes

Chemical-free PCB manufacturing involves the use of alternative materials and processes that are less harmful to human health and the environment. Some of these include:

- Lead-free solders

- Halogen-free laminates

- Water-based cleaning agents

- Plasma etching

By replacing hazardous chemicals with safer alternatives, manufacturers can significantly reduce the negative impact of PCB fabrication and assembly.

Benefits of Chemical-Free PCB Manufacturing

Improved Worker Safety

One of the primary benefits of chemical-free PCB manufacturing is the improved safety of workers involved in the process. By eliminating or minimizing exposure to hazardous chemicals, the risk of health problems associated with these substances is greatly reduced. This leads to a healthier and more productive workforce.

Reduced Environmental Impact

Chemical-free PCB manufacturing also contributes to a cleaner and more sustainable environment. By reducing the use of hazardous chemicals, the risk of air, water, and soil pollution is minimized. This helps preserve natural resources and protects wildlife from the harmful effects of chemical contamination.

Compliance with Regulations

Adopting chemical-free PCB manufacturing practices enables companies to comply with various environmental regulations and directives. This not only helps them avoid penalties and legal issues but also enhances their reputation as socially responsible businesses.

Cost Savings

While the initial investment in chemical-free PCB manufacturing may be higher, it can lead to long-term cost savings. By reducing the need for hazardous waste disposal and minimizing the risk of environmental liabilities, companies can save money in the long run.

Challenges and Limitations

Despite the numerous benefits of chemical-free PCB manufacturing, there are some challenges and limitations that need to be addressed:

- Limited availability of alternative materials

- Higher initial costs

- Resistance to change in the industry

- Lack of awareness and education

Overcoming these challenges requires collaboration between manufacturers, suppliers, and regulatory bodies to promote the adoption of chemical-free practices and develop cost-effective solutions.

FAQs

-

Q: What are the most common hazardous chemicals used in conventional PCB manufacturing?

A: The most common hazardous chemicals used in conventional PCB manufacturing include lead, mercury, cadmium, beryllium, and hexavalent chromium. -

Q: What are the health risks associated with exposure to these hazardous chemicals?

A: Exposure to hazardous chemicals used in PCB manufacturing can lead to respiratory issues, skin irritation and allergies, neurological disorders, cancer, and reproductive health problems. -

Q: What initiatives have been taken to promote chemical-free PCB manufacturing?

A: Initiatives such as the Restriction of Hazardous Substances (RoHS) Directive, Waste Electrical and Electronic Equipment (WEEE) Directive, and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) Regulation have been implemented to promote chemical-free PCB manufacturing. -

Q: What are some alternative materials and processes used in chemical-free PCB manufacturing?

A: Alternative materials and processes used in chemical-free PCB manufacturing include lead-free solders, halogen-free laminates, water-based cleaning agents, and plasma etching. -

Q: What are the benefits of adopting chemical-free PCB manufacturing practices?

A: The benefits of adopting chemical-free PCB manufacturing practices include improved worker safety, reduced environmental impact, compliance with regulations, and potential cost savings in the long run.

Conclusion

The need for chemical-free PCB fabrication and assembly is becoming increasingly evident as the world becomes more aware of the health and environmental risks associated with hazardous chemicals. By adopting alternative materials and processes, manufacturers can contribute to a safer and more sustainable future for the electronics industry.

While there are challenges to overcome, the benefits of chemical-free PCB manufacturing far outweigh the limitations. As more companies embrace this approach, we can expect to see a significant reduction in the negative impact of electronic manufacturing on human health and the environment.

It is crucial for all stakeholders – manufacturers, suppliers, regulatory bodies, and consumers – to work together to promote the adoption of chemical-free PCB manufacturing practices. By raising awareness, investing in research and development, and implementing supportive policies, we can create a cleaner, safer, and more responsible electronics industry for generations to come.

Leave a Reply