What are Thermal Pads?

Thermal pads are thin, flexible materials that are placed between electronic components and heat sinks to enhance thermal conductivity. These pads are typically made from materials such as silicone, graphite, or ceramic-filled elastomers, which possess excellent thermal properties and can conform to the irregular surfaces of electronic components and heat sinks.

The primary function of thermal pads is to fill the microscopic air gaps between the surfaces of electronic components and heat sinks. By eliminating these air gaps, thermal pads create a continuous path for heat to flow from the heat source to the heat sink, thereby improving the overall thermal management of the system.

Thermal Pad Properties

To effectively transfer heat, thermal pads must possess several key properties:

-

High thermal conductivity: Thermal pads should have a high thermal conductivity value, typically measured in Watts per meter-Kelvin (W/mK), to ensure efficient heat transfer.

-

Low thermal resistance: A low thermal resistance allows heat to flow more easily through the pad, minimizing the temperature difference between the heat source and the heat sink.

-

Conformability: Thermal pads must be able to conform to the irregular surfaces of electronic components and heat sinks, ensuring optimal contact and minimizing air gaps.

-

Durability: Thermal pads should be able to withstand the operating temperatures and environmental conditions of the application without degrading or losing their thermal properties over time.

Applications of Thermal Pads in Circuit Board Manufacturing

Thermal pads find extensive use in various aspects of circuit board manufacturing, including:

Power Electronics

In power electronic applications, such as switch-mode power supplies, voltage regulators, and motor controllers, thermal pads are used to dissipate heat from high-power components like MOSFETs, IGBTs, and diodes. By efficiently transferring heat to heat sinks or other cooling solutions, thermal pads help maintain the operating temperature of these components within safe limits, preventing thermal runaway and ensuring reliable operation.

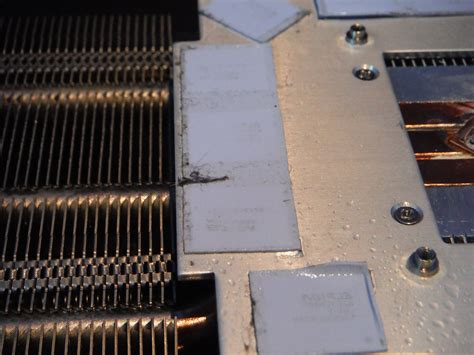

Microprocessors and GPUs

Modern microprocessors and graphics processing units (GPUs) generate significant amounts of heat due to their high clock speeds and transistor densities. Thermal pads are used to interface these components with heat sinks or liquid cooling solutions, ensuring optimal thermal performance and preventing throttling or shutdown due to overheating.

LED Lighting

High-power LED lighting applications, such as street lights, automotive headlights, and industrial lighting, rely on thermal pads to dissipate heat from the LED packages to the heat sinks. Effective thermal management is crucial in these applications to maintain the light output, color consistency, and longevity of the LEDs.

Automotive Electronics

The harsh operating environment of automotive electronics, which includes high temperatures, vibrations, and exposure to moisture and contaminants, necessitates the use of high-performance thermal pads. These pads are used in various automotive electronic systems, such as engine control units, power inverters, and battery management systems, to ensure reliable operation and prevent premature failure due to thermal stress.

Factors Affecting Thermal Pad Performance

Several factors influence the performance of thermal pads in circuit board manufacturing:

Thermal Conductivity

The thermal conductivity of the pad material is a primary factor in determining its heat transfer capabilities. Higher thermal conductivity values indicate better heat transfer performance. Common thermal pad materials and their typical thermal conductivity ranges are:

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Silicone | 0.5 – 2.0 |

| Graphite-filled silicone | 2.0 – 5.0 |

| Ceramic-filled silicone | 1.0 – 3.0 |

| Boron nitride-filled | 3.0 – 10.0 |

Thickness and Compression

The thickness of the thermal pad and the amount of compression applied during installation can significantly impact its thermal performance. Thinner pads generally have lower thermal resistance, as heat has to travel a shorter distance through the material. However, thinner pads may not be able to sufficiently fill the air gaps between the surfaces, leading to reduced thermal performance.

Compression of the thermal pad during installation helps to minimize air gaps and ensure optimal contact between the surfaces. The ideal amount of compression depends on the specific pad material and the surface roughness of the components. Over-compression can lead to damage to the components or the pad itself, while under-compression can result in poor thermal performance due to air gaps.

Surface Roughness and Contact Resistance

The surface roughness of the electronic component and heat sink can affect the thermal performance of the pad. Rough surfaces have more air gaps, which can impede heat transfer. Thermal pads with higher conformability can better fill these air gaps, improving thermal performance.

Contact resistance, which is the resistance to heat flow at the interfaces between the thermal pad and the surfaces, also plays a role in thermal performance. Factors such as surface roughness, contamination, and the presence of oxidation or other surface treatments can increase contact resistance and reduce thermal performance.

Best Practices for Thermal Pad Selection and Installation

To ensure optimal thermal performance in circuit board manufacturing, consider the following best practices when selecting and installing thermal pads:

-

Choose a thermal pad with a thermal conductivity and thickness appropriate for the application, taking into account the power dissipation of the components and the available space.

-

Ensure that the thermal pad material is compatible with the operating environment and the surfaces of the components, considering factors such as temperature range, humidity, and chemical exposure.

-

Properly clean and prepare the surfaces of the electronic components and heat sinks before installing the thermal pad to minimize contact resistance.

-

Apply the appropriate amount of compression to the thermal pad during installation, following the manufacturer’s guidelines to ensure optimal contact and minimize air gaps.

-

Regularly inspect and maintain the thermal pads, replacing them if they show signs of degradation or damage, to ensure consistent thermal performance over the life of the electronic device.

Frequently Asked Questions (FAQ)

-

What is the difference between a thermal pad and thermal paste?

Thermal pads are pre-cut, solid materials that are placed between electronic components and heat sinks, while thermal paste is a viscous liquid that is applied directly to the surfaces. Thermal pads are easier to install and remove, but thermal paste generally offers better thermal performance due to its ability to fill microscopic air gaps more effectively. -

Can thermal pads be reused?

In most cases, thermal pads should not be reused, as they can become compressed, contaminated, or damaged during removal, which can negatively impact their thermal performance. It is generally recommended to use a new thermal pad each time a component is installed or replaced. -

How do I choose the right thickness for a thermal pad?

The choice of thermal pad thickness depends on factors such as the power dissipation of the electronic component, the surface roughness of the component and heat sink, and the available space. Thinner pads generally have lower thermal resistance but may not be able to fill larger air gaps. It is essential to consult the manufacturer’s guidelines and consider the specific requirements of the application when selecting the appropriate thickness. -

Can thermal pads be cut to size?

Yes, thermal pads can be cut to size using scissors or a sharp knife to fit the specific dimensions of the electronic component and heat sink. However, it is important to ensure that the cut edges are clean and free from debris, as this can interfere with the thermal performance of the pad. -

How do I ensure optimal contact between the thermal pad and the surfaces?

To ensure optimal contact, the surfaces of the electronic component and heat sink should be clean and free from dirt, grease, or other contaminants. The thermal pad should be installed with the appropriate amount of compression, following the manufacturer’s guidelines. Proper compression helps to minimize air gaps and ensure optimal heat transfer between the surfaces.

In conclusion, thermal pads play a critical role in the thermal management of circuit boards, ensuring the reliable operation and longevity of electronic devices. By understanding the properties, applications, and factors affecting thermal pad performance, designers and manufacturers can make informed decisions when selecting and installing these essential components. As electronic devices continue to increase in power density and complexity, the importance of effective thermal management solutions, such as thermal pads, will only continue to grow.

Leave a Reply