What is PCB Assembly?

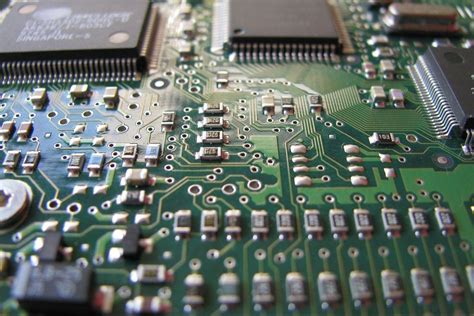

PCB assembly is the process of soldering or mounting electronic components onto a printed circuit board (PCB). The PCB serves as the foundation for the electronic device, providing electrical connections and mechanical support for the components. PCB assembly involves several steps, including:

- Solder paste application

- Component placement

- Reflow soldering

- Inspection and testing

Types of PCB Assembly

There are two main types of PCB assembly:

- Through-hole assembly (THA): Components with long leads are inserted through holes drilled in the PCB and soldered on the opposite side.

- Surface mount assembly (SMA): Components are placed directly onto pads on the surface of the PCB and soldered in place.

| Assembly Type | Advantages | Disadvantages |

|---|---|---|

| Through-hole | – Strong mechanical bonds – Easier for manual assembly |

– Larger components – Higher assembly costs |

| Surface mount | – Smaller components – Higher component density |

– Requires specialized equipment |

Turnkey PCB Assembly Services

Turnkey PCB assembly services provide a complete solution for customers, from PCB design and fabrication to component sourcing and final assembly. The benefits of using a turnkey service include:

- Streamlined process

- Reduced costs

- Faster time-to-market

- Expert support

PCB Design and Fabrication

A turnkey PCB assembly service provider can assist with PCB design and fabrication. This includes:

- Schematic capture

- PCB layout

- Design for manufacturability (DFM) analysis

- Prototype and production fabrication

PCB Design Software

Some popular PCB design software tools include:

- Altium Designer

- Cadence OrCAD

- Autodesk Eagle

- KiCad

Component Sourcing

Turnkey PCB assembly providers can source components on behalf of their customers. This includes:

- Part selection and optimization

- Supplier management

- Inventory management

- Component traceability

Common Electronic Components

| Component Type | Examples |

|---|---|

| Passive | Resistors, capacitors, inductors |

| Active | Transistors, diodes, integrated circuits (ICs) |

| Electromechanical | Switches, connectors, relays |

Assembly Process

The PCB assembly process typically involves the following steps:

- Solder paste application: Solder paste is applied to the pads on the PCB using a stencil or screen printing process.

- Component placement: Components are placed onto the PCB using automated pick-and-place machines or manual assembly.

- Reflow soldering: The PCB is heated in a reflow oven, melting the solder paste and forming electrical connections between the components and the PCB.

- Inspection and testing: The assembled PCB is inspected for defects and tested for functionality.

Soldering Techniques

| Technique | Description |

|---|---|

| Wave soldering | Components are passed over a wave of molten solder |

| Reflow soldering | Solder paste is melted in a reflow oven |

| Hand soldering | Components are soldered manually using a soldering iron |

Quality Control and Testing

Turnkey PCB assembly services should have robust quality control and testing procedures in place. This includes:

- Automated optical inspection (AOI)

- X-ray inspection

- In-circuit testing (ICT)

- Functional testing

Common PCB Defects

| Defect Type | Description |

|---|---|

| Solder bridge | Unintended connection between two or more pads |

| Tombstone | Component stands up on one end due to uneven solder reflow |

| Cold solder joint | Solder joint with poor electrical and mechanical properties |

Choosing a Turnkey PCB Assembly Service Provider

When selecting a turnkey PCB assembly service provider, consider the following factors:

- Experience and expertise

- Manufacturing capabilities

- Quality control and testing procedures

- Customer support and communication

- Pricing and lead times

Questions to Ask a Potential Service Provider

- What types of PCBs can you assemble (e.g., rigid, flexible, high-density)?

- What are your minimum and maximum order quantities?

- Do you offer prototype and low-volume production services?

- What is your typical lead time for assembly?

- What certifications do you hold (e.g., ISO 9001, IPC-A-610)?

Case Studies and Success Stories

Company A: Medical Device Manufacturer

Company A, a medical device manufacturer, partnered with a turnkey PCB assembly service provider to develop a new wearable device. The service provider assisted with PCB design, component sourcing, and assembly, resulting in a successful product launch and reduced time-to-market.

Company B: Automotive Electronics Supplier

Company B, an automotive electronics supplier, outsourced their PCB assembly to a turnkey service provider. The service provider implemented strict quality control procedures, including AOI and X-ray inspection, to ensure the reliability of the assembled PCBs. This allowed Company B to focus on their core competencies and improve overall product quality.

FAQ

1. What is the difference between PCB fabrication and PCB assembly?

PCB fabrication is the process of manufacturing the bare printed circuit board, while PCB assembly involves soldering or mounting electronic components onto the fabricated PCB.

2. Can turnkey PCB assembly services handle both through-hole and surface mount components?

Yes, most turnkey PCB assembly service providers are equipped to handle both through-hole and surface mount component assembly.

3. How long does the PCB assembly process typically take?

The lead time for PCB assembly depends on various factors, such as the complexity of the design, the number of components, and the order quantity. Typical lead times can range from a few days to several weeks.

4. What are the advantages of using a turnkey PCB assembly service compared to in-house assembly?

The advantages of using a turnkey PCB assembly service include access to specialized equipment and expertise, reduced labor and overhead costs, and faster time-to-market.

5. How can I ensure the quality of the assembled PCBs?

To ensure the quality of the assembled PCBs, choose a turnkey service provider with robust quality control and testing procedures, such as automated optical inspection (AOI), X-ray inspection, and functional testing. Additionally, look for providers with relevant certifications, such as ISO 9001 and IPC-A-610.

Conclusion

Turnkey PCB assembly services provide a comprehensive solution for companies looking to outsource their PCB assembly needs. By partnering with an experienced and reliable service provider, businesses can benefit from streamlined processes, reduced costs, and faster time-to-market. When selecting a turnkey PCB assembly service provider, consider factors such as experience, manufacturing capabilities, quality control procedures, and customer support to ensure a successful partnership.

Leave a Reply