Automated Optical Inspection (AOI)

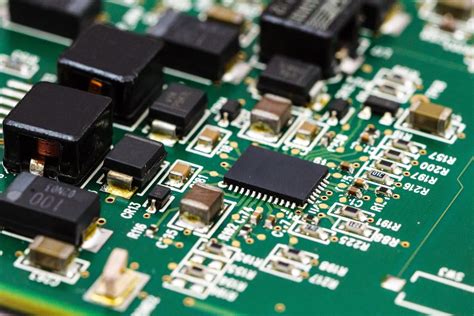

One of the most important strategies for ensuring the quality and reliability of automotive PCBs is the use of automated optical inspection (AOI). AOI systems use high-resolution cameras and advanced image processing software to inspect PCBs for defects such as missing components, incorrect component placement, and solder joint issues.

| Benefits of AOI | Description |

|---|---|

| Improved Accuracy | AOI systems can detect defects that are difficult or impossible for human inspectors to see, resulting in higher quality PCBs. |

| Increased Speed | AOI systems can inspect PCBs much faster than human inspectors, allowing for higher production volumes. |

| Reduced Costs | By catching defects early in the assembly process, AOI systems can reduce the costs associated with rework and scrap. |

There are several types of AOI systems used in automotive PCB assembly, including:

2D AOI

2D AOI systems use a single camera to capture images of the PCB from directly above. These systems are effective at detecting surface-level defects such as missing components and incorrect component placement.

3D AOI

3D AOI systems use multiple cameras or laser scanners to create a three-dimensional model of the PCB. This allows for the detection of defects that may not be visible from a single angle, such as lifted leads or insufficient solder volume.

AI-Powered AOI

The latest development in AOI technology is the use of artificial intelligence (AI) and machine learning algorithms to analyze PCB images. AI-powered AOI systems can learn to recognize defects based on a large dataset of known good and bad PCBs, resulting in even higher accuracy and faster inspection times.

Selective Soldering

Another innovative strategy for automotive PCB assembly is selective soldering. This technique involves applying solder only to specific areas of the PCB, rather than the entire board. Selective soldering is particularly useful for PCBs with a mix of through-hole and surface-mount components, as it allows for precise control over the soldering process.

| Advantages of Selective Soldering | Description |

|---|---|

| Reduced Thermal Stress | By applying heat only to specific areas of the PCB, selective soldering reduces the risk of thermal damage to sensitive components. |

| Improved Solder Joint Quality | Selective soldering allows for precise control over the amount of solder applied to each joint, resulting in stronger and more reliable connections. |

| Increased Efficiency | Selective soldering is faster than manual soldering and can be automated for high-volume production. |

There are several types of selective soldering machines used in automotive PCB assembly, including:

Laser Selective Soldering

Laser selective soldering machines use a focused laser beam to heat and melt solder paste at specific points on the PCB. This allows for highly precise and repeatable soldering, even on small or delicate components.

Mini-Wave Selective Soldering

Mini-wave selective soldering machines use a small wave of molten solder to selectively solder through-hole components. The PCB is passed over the wave, allowing the solder to flow into the component leads and create a strong joint.

Conformal Coating

Conformal coating is a process that involves applying a thin, protective layer over the surface of a PCB. This coating helps to protect the PCB from environmental factors such as moisture, dust, and chemicals, as well as providing insulation against electrical shorts.

| Benefits of Conformal Coating | Description |

|---|---|

| Improved Reliability | Conformal coating helps to prevent corrosion and other types of damage that can cause PCB failures, resulting in more reliable electronics. |

| Enhanced Durability | The protective layer provided by conformal coating allows PCBs to withstand harsh environments and extreme temperatures. |

| Reduced Costs | By extending the lifespan of PCBs and reducing the need for repairs or replacements, conformal coating can help to lower overall costs. |

There are several types of conformal coatings used in automotive PCB assembly, including:

Acrylic Coatings

Acrylic conformal coatings are known for their excellent moisture resistance and ease of application. They are often used in applications where the PCB will be exposed to high humidity or condensation.

Silicone Coatings

Silicone conformal coatings offer excellent protection against extreme temperatures and UV light. They are commonly used in automotive applications where the PCB may be exposed to high heat or direct sunlight.

Parylene Coatings

Parylene conformal coatings are applied using a vapor deposition process, resulting in a thin, pinhole-free layer that provides excellent protection against moisture and chemicals. They are often used in high-reliability automotive applications such as safety-critical systems.

Potting and Encapsulation

Potting and encapsulation are processes that involve completely encasing a PCB or electronic component in a protective material, such as epoxy or silicone. This provides an even higher level of protection than conformal coating, as it fully seals the PCB from the environment.

| Advantages of Potting and Encapsulation | Description |

|---|---|

| Maximum Protection | By fully encasing the PCB, potting and encapsulation provide the highest level of protection against moisture, dust, and other environmental hazards. |

| Improved Mechanical Strength | The encapsulation material helps to support and strengthen the PCB, reducing the risk of damage from vibration or physical shock. |

| Enhanced Thermal Management | Some potting and encapsulation materials have high thermal conductivity, allowing for better heat dissipation and improved thermal management of the PCB. |

There are several types of potting and encapsulation materials used in automotive PCB assembly, including:

Epoxy Resins

Epoxy resins are the most common type of potting and encapsulation material. They offer excellent mechanical strength, moisture resistance, and electrical insulation properties.

Silicone Gels

Silicone gels are softer and more flexible than epoxy resins, making them ideal for applications where the PCB may be subject to thermal expansion or mechanical stress. They also provide excellent protection against moisture and chemicals.

Automated Component Placement

Automated component placement is a key strategy for improving the speed and accuracy of automotive PCB assembly. This involves using machines to pick and place components onto the PCB, rather than relying on manual labor.

| Benefits of Automated Component Placement | Description |

|---|---|

| Increased Speed | Automated placement machines can place components much faster than human operators, allowing for higher production volumes. |

| Improved Accuracy | Automated machines can place components with extremely high precision, reducing the risk of misaligned or missing components. |

| Reduced Labor Costs | By automating the component placement process, manufacturers can reduce labor costs and improve overall efficiency. |

There are several types of automated component placement machines used in automotive PCB assembly, including:

Pick-and-Place Machines

Pick-and-place machines use a robotic arm or gantry system to pick up components from a feeder and place them onto the PCB. These machines can be programmed to handle a wide variety of component types and sizes.

Chip Shooters

Chip shooters are specialized placement machines designed for high-speed placement of small, lightweight components such as resistors and capacitors. They use a rotating turret to pick up and shoot components onto the PCB at a rate of several thousand per hour.

Multi-Function Placement Machines

Multi-function placement machines combine the capabilities of pick-and-place machines and chip shooters into a single system. This allows for greater flexibility and efficiency in handling a mix of component types and sizes.

Automated Soldering

In addition to automated component placement, automated soldering is another key strategy for improving the efficiency and reliability of automotive PCB assembly. This involves using machines to apply solder paste and reflow the PCB, rather than relying on manual soldering methods.

| Advantages of Automated Soldering | Description |

|---|---|

| Consistent Quality | Automated soldering machines can apply solder paste and reflow the PCB with a high degree of consistency, resulting in fewer defects and higher overall quality. |

| Increased Throughput | Automated soldering is much faster than manual soldering, allowing for higher production volumes and shorter lead times. |

| Reduced Labor Costs | By automating the soldering process, manufacturers can reduce labor costs and improve overall efficiency. |

There are several types of automated soldering machines used in automotive PCB assembly, including:

Stencil Printers

Stencil printers are used to apply solder paste to the PCB prior to component placement. They use a stencil with cut-outs that match the pads on the PCB, allowing for precise and consistent application of solder paste.

Reflow Ovens

Reflow ovens are used to melt the solder paste and form a permanent connection between the components and the PCB. They use a controlled heating profile to gradually raise the temperature of the PCB until the solder melts and flows around the component leads.

Wave Soldering Machines

Wave soldering machines are used for soldering through-hole components on the bottom side of the PCB. They use a wave of molten solder to create a strong and reliable joint between the component leads and the PCB pads.

FAQ

What are the benefits of using AOI in automotive PCB assembly?

AOI systems offer several benefits in automotive PCB assembly, including improved accuracy, increased speed, and reduced costs. By using high-resolution cameras and advanced image processing software, AOI systems can detect defects that are difficult or impossible for human inspectors to see, resulting in higher quality PCBs. They can also inspect PCBs much faster than human inspectors, allowing for higher production volumes. Finally, by catching defects early in the assembly process, AOI systems can reduce the costs associated with rework and scrap.

How does selective soldering improve the quality of automotive PCBs?

Selective soldering allows for precise control over the soldering process, resulting in stronger and more reliable solder joints. By applying solder only to specific areas of the PCB, selective soldering reduces the risk of thermal damage to sensitive components. It also allows for precise control over the amount of solder applied to each joint, ensuring that the joint is strong enough to withstand the stresses of automotive use.

What types of conformal coatings are used in automotive PCB assembly?

There are several types of conformal coatings used in automotive PCB assembly, each with its own unique properties. Acrylic coatings are known for their excellent moisture resistance and ease of application, making them a popular choice for high-humidity environments. Silicone coatings offer excellent protection against extreme temperatures and UV light, making them ideal for automotive applications where the PCB may be exposed to high heat or direct sunlight. Parylene coatings are applied using a vapor deposition process and provide a thin, pinhole-free layer that offers excellent protection against moisture and chemicals.

How does automated component placement improve the efficiency of automotive PCB assembly?

Automated component placement machines can place components much faster and with greater precision than human operators, allowing for higher production volumes and fewer defects. By using machines to pick and place components onto the PCB, manufacturers can reduce labor costs and improve overall efficiency. There are several types of automated component placement machines used in automotive PCB assembly, including pick-and-place machines, chip shooters, and multi-function placement machines, each with its own unique capabilities.

What are the advantages of using automated soldering in automotive PCB assembly?

Automated soldering offers several advantages over manual soldering methods, including consistent quality, increased throughput, and reduced labor costs. By using machines to apply solder paste and reflow the PCB, manufacturers can ensure a high degree of consistency and reduce the risk of defects. Automated soldering is also much faster than manual soldering, allowing for higher production volumes and shorter lead times. Finally, by automating the soldering process, manufacturers can reduce labor costs and improve overall efficiency.

Leave a Reply