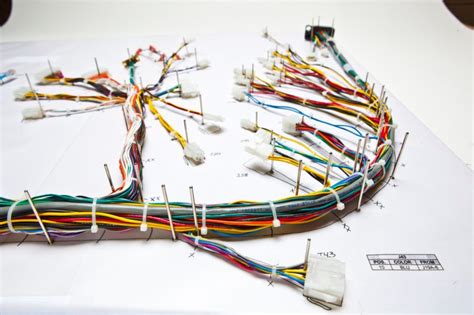

Introduction to Cable and Wire Harness Assembly

Cable and wire harness assembly is a critical component in various industries, including automotive, aerospace, medical, and telecommunications. The primary function of a cable and wire harness is to transmit power and data signals between different parts of a system or device. Selecting the right cable and wire harness assembly is crucial for ensuring the optimal performance, reliability, and durability of your final product.

Key Factors to Consider when Choosing Cable and Wire Harness Assembly

When selecting a cable and wire harness assembly for your product, there are several key factors to consider:

1. Application and Environment

The first step in selecting the appropriate cable and wire harness is to understand the specific application and environment in which it will be used. Different applications may require different types of cables and connectors, as well as different levels of protection against environmental factors such as temperature, humidity, and chemical exposure.

2. Electrical Requirements

The electrical requirements of your system or device will determine the type and size of the cables and wires needed for your harness assembly. Factors to consider include:

- Voltage and current rating

- Insulation material and thickness

- Conductor material and size

- Shielding requirements

3. Mechanical Requirements

The mechanical requirements of your cable and wire harness assembly will depend on the physical layout and design of your system or device. Factors to consider include:

- Length and routing of the harness

- Flexibility and bend radius

- Vibration and shock resistance

- Strain relief and connector retention

4. Regulatory Compliance

Depending on your industry and application, there may be specific regulatory requirements that your cable and wire harness assembly must meet. These may include:

- UL, CSA, or CE certification

- RoHS and REACH compliance

- Mil-Spec or aerospace standards

5. Cost and Lead Time

Finally, cost and lead time are important considerations when selecting a cable and wire harness assembly supplier. While it may be tempting to choose the lowest-cost option, it’s important to balance cost with quality and reliability. Additionally, lead times can vary significantly between suppliers, so it’s important to choose a supplier that can meet your production schedule.

Types of Cable and Wire used in Harness Assembly

There are several types of cables and wires commonly used in harness assemblies, each with its own unique properties and applications.

| Cable/Wire Type | Description | Common Applications |

|---|---|---|

| PVC Cable | Polyvinyl chloride insulation, general-purpose | Automotive, appliances |

| Teflon Cable | PTFE insulation, high-temperature and chemical resistance | Aerospace, medical |

| Coaxial Cable | Inner conductor, dielectric insulation, outer conductor, outer jacket | Telecommunications, video |

| Twisted Pair | Two insulated wires twisted together, reduces crosstalk | Networking, audio |

| Ribbon Cable | Multiple conductors arranged in a flat ribbon | Electronics, computer peripherals |

Connector Types and Termination Methods

The choice of connector type and termination method can have a significant impact on the performance and reliability of your cable and wire harness assembly.

Connector Types

- Circular Connectors: Compact, robust connectors commonly used in aerospace and military applications. Common series include MIL-DTL-5015, MIL-DTL-38999, and D38999.

- Rectangular Connectors: Modular connectors used in a wide range of applications, including automotive and industrial. Examples include Molex, AMP, and JST connectors.

- D-Subminiature (D-Sub): Commonly used in computer and telecommunications applications, with a trapezoidal shell and two or more rows of pins.

- RJ45: Standard connector for Ethernet networking, with eight pins and a locking tab.

Termination Methods

- Soldering: A permanent and reliable method of terminating wires to connectors or printed circuit boards (PCBs). Requires skilled operators and specialized equipment.

- Crimping: A fast and cost-effective method of terminating wires to connectors using a crimp tool and crimp contacts. Provides a secure, gas-tight connection.

- Insulation Displacement (IDC): A method of terminating wires to connectors or PCBs by piercing the insulation and making contact with the conductor. Commonly used with ribbon cables and modular connectors.

- Ultrasonic welding: A high-speed, high-strength welding process that uses ultrasonic vibrations to join wires to terminals or connectors. Commonly used in automotive and medical applications.

Design Considerations for Cable and Wire Harness Assembly

Proper design of your cable and wire harness assembly is critical for ensuring optimal performance, reliability, and manufacturability. Some key design considerations include:

1. Wire Gauge and Insulation

The wire gauge and insulation material should be selected based on the electrical and environmental requirements of your application. Factors to consider include:

- Current-carrying capacity

- Voltage drop

- Insulation temperature rating

- Flexibility and bend radius

2. Shielding and Grounding

Proper shielding and grounding are essential for reducing electromagnetic interference (EMI) and ensuring signal integrity. Factors to consider include:

- Type of shielding (foil, braid, or both)

- Shielding coverage and termination

- Grounding points and methods

3. Strain Relief and Bend Radius

Adequate strain relief and bend radius are important for preventing damage to the cables and wires during installation and use. Factors to consider include:

- Type of strain relief (molded, clamped, or tied)

- Bend radius and routing of cables

- Vibration and shock isolation

4. Labeling and Identification

Clear and durable labeling and identification of cables, wires, and connectors are essential for ease of assembly, troubleshooting, and maintenance. Factors to consider include:

- Type of labeling (heat-shrink, adhesive, or printed)

- Color-coding and wire marking

- Connector and pin identification

Testing and Quality Control

Thorough testing and quality control are critical for ensuring the reliability and performance of your cable and wire harness assembly. Some common testing methods include:

1. Continuity and Resistance Testing

Continuity testing verifies that there are no open or short circuits in the harness assembly, while resistance testing measures the resistance of individual wires and connections.

2. Insulation Resistance Testing

Insulation resistance testing measures the resistance between conductors and the harness shield or ground, to ensure adequate insulation and prevent leakage currents.

3. Hipot Testing

High potential (hipot) testing applies a high voltage between conductors and the harness shield or ground, to verify the integrity of the insulation and detect any potential breakdown or arcing.

4. Functional Testing

Functional testing verifies that the harness assembly performs as intended in the final product, including all electrical and mechanical functions.

Frequently Asked Questions (FAQ)

- What is the difference between a cable and a wire harness?

-

A cable typically refers to a single insulated conductor or a group of conductors enclosed in a single jacket. A wire harness, on the other hand, is an assembly of multiple cables and wires that are bundled together and terminated with connectors or other hardware.

-

How do I choose the right wire gauge for my harness assembly?

-

The choice of wire gauge depends on several factors, including the current-carrying capacity, voltage drop, and mechanical strength required for your application. You can refer to industry standards such as the American Wire Gauge (AWG) or the ISO metric wire sizes to select the appropriate gauge based on your requirements.

-

What are the advantages of using a custom cable and wire harness assembly?

-

Custom cable and wire harness assemblies offer several advantages over off-the-shelf solutions, including:

- Optimized design for your specific application and environment

- Reduced assembly time and cost

- Improved reliability and performance

- Simplified inventory management and logistics

-

How can I ensure the reliability and durability of my cable and wire harness assembly?

-

There are several steps you can take to ensure the reliability and durability of your harness assembly:

- Choose high-quality materials and components

- Follow best practices for design, manufacturing, and testing

- Use appropriate strain relief and protection methods

- Perform regular inspections and maintenance

-

What are some common challenges in cable and wire harness assembly, and how can they be addressed?

- Some common challenges in cable and wire harness assembly include:

- Managing complex designs and large assemblies

- Ensuring consistent quality and reliability

- Meeting tight tolerances and specifications

- Dealing with long lead times and supply chain issues

- These challenges can be addressed by:

- Using computer-aided design (CAD) and manufacturing (CAM) tools

- Implementing strict quality control and testing procedures

- Collaborating closely with suppliers and manufacturers

- Optimizing inventory management and logistics processes

Conclusion

Selecting the right cable and wire harness assembly is critical for ensuring the performance, reliability, and durability of your final product. By considering factors such as application requirements, electrical and mechanical specifications, regulatory compliance, and cost and lead time, you can make an informed decision and choose the best solution for your needs.

Proper design, manufacturing, and testing are also essential for ensuring the quality and reliability of your harness assembly. By following best practices and working closely with experienced suppliers and manufacturers, you can overcome common challenges and achieve optimal results.

Leave a Reply