What are Gerber files?

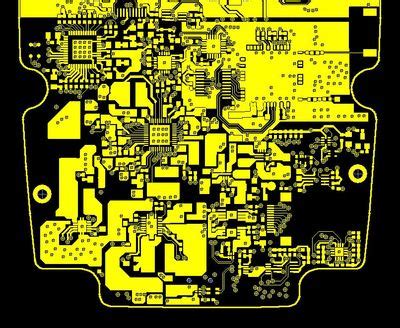

Gerber files are a standard file format used in the printed circuit board (PCB) industry to describe the layout and design of a PCB. They are named after the Gerber Scientific Instrument Company, which developed the format in the 1960s. Gerber files contain all the necessary information for a PCB manufacturer to produce a physical board, including the copper layers, solder mask, silkscreen, and drill holes.

Components of a Gerber file set

A complete Gerber file set typically consists of the following files:

- Copper layers (e.g., Top Layer, Bottom Layer, Inner Layers)

- Solder Mask layers (e.g., Top Solder Mask, Bottom Solder Mask)

- Silkscreen layers (e.g., Top Silkscreen, Bottom Silkscreen)

- Drill files (e.g., Excellon drill file, Drill drawing)

- Outline/Dimension layer

- Paste Mask layers (optional, for surface mount technology)

Each file represents a specific aspect of the PCB design and is used by the manufacturer during different stages of the production process.

The importance of Gerber files in PCB manufacturing

1. Communication between designer and manufacturer

Gerber files serve as the primary means of communication between the PCB designer and the manufacturer. They provide a standardized way to convey the design intent and ensure that the manufacturer has all the necessary information to produce the board accurately.

2. Design verification and error prevention

By reviewing the Gerber files, both the designer and the manufacturer can verify the PCB design for potential issues, such as incorrect layer alignment, missing features, or design rule violations. This helps prevent errors and ensures that the final product meets the intended specifications.

3. Automated manufacturing processes

Gerber files are used to drive the various machines and processes involved in PCB manufacturing, such as:

- Photoplotter: Creates the photomasks used for exposing the copper layers

- CNC drill: Drills the holes in the PCB based on the drill file information

- Solder mask application: Applies the solder mask layer according to the Gerber file data

- Silkscreen printing: Prints the component labels and other text on the PCB surface

By using Gerber files, manufacturers can automate these processes, ensuring high precision, repeatability, and efficiency in production.

4. Consistency and reliability

Gerber files provide a consistent and reliable format for exchanging PCB design data. This standardization helps minimize misinterpretation and errors that may arise from using alternative or proprietary file formats.

Creating accurate Gerber files

To ensure that your PCB is manufactured correctly, it is essential to create accurate and complete Gerber files. Here are some best practices to follow:

1. Use a reputable PCB design software

Choose a well-established PCB design software that has built-in tools for generating Gerber files. Popular options include Altium Designer, KiCad, Eagle, and OrCAD.

2. Follow the manufacturer’s specifications

Consult with your chosen PCB manufacturer for their specific requirements and guidelines for Gerber file submission. This may include file naming conventions, layer stack-up information, and minimum feature sizes.

3. Verify the Gerber files before submission

After generating the Gerber files, review them using a Gerber viewer software to ensure that all layers are correctly aligned, and the design matches your intended specifications. Some popular Gerber viewers include GC-Prevue, ViewMate, and Gerbv.

4. Include all necessary files

Make sure to include all the required Gerber files in your submission package, as mentioned in the “Components of a Gerber file set” section above. Missing files can lead to delays in manufacturing or incorrect board production.

5. Communicate any special requirements

If your PCB design has any special requirements, such as controlled impedance, specific material preferences, or non-standard features, communicate these clearly to the manufacturer and include relevant information in your Gerber file submission.

Gerber file formats and versions

Over the years, the Gerber file format has evolved to accommodate advancements in PCB design and manufacturing technologies. The two most common Gerber file formats in use today are:

- Extended Gerber (RS-274X)

- Introduced in 1998 as an extension to the original Gerber format

- Includes aperture definitions and other enhancements for improved accuracy and efficiency

-

Widely supported by PCB design software and manufacturers

-

Gerber X2

- Released in 2014 as a successor to Extended Gerber

- Adds embedded metadata and attributes to provide more context and intelligence to the design data

- Supports advanced features such as complex pad shapes and net connectivity information

- Gradually gaining adoption in the industry

When creating Gerber files, it is essential to use the most appropriate and widely supported format based on your PCB design software and manufacturer’s capabilities. Extended Gerber (RS-274X) is currently the most common and universally accepted format.

Frequently Asked Questions (FAQ)

- What is the difference between Gerber files and other PCB design files like Eagle or Altium?

-

Gerber files are a generic, industry-standard format for describing PCB designs, while files from Eagle, Altium, or other PCB design software are typically proprietary and specific to those tools. Gerber files are used for manufacturing, while design files are used for creating and editing the PCB layout.

-

Can I use Gerber files for PCB Assembly?

-

Gerber files primarily contain information for PCB fabrication, not assembly. For assembly purposes, additional files like Bill of Materials (BOM), pick-and-place files, and centroid data are required.

-

What happens if I submit incomplete or incorrect Gerber files to a manufacturer?

-

Submitting incomplete or incorrect Gerber files can lead to manufacturing delays, as the manufacturer will need to request clarification or corrections. In some cases, it may result in the production of incorrect boards, which can be costly and time-consuming to rectify.

-

Are there any alternatives to Gerber files for PCB manufacturing?

-

While Gerber files are the most widely used format, some alternatives include ODB++ (Open Database++), IPC-2581, and IPC-2591. However, these formats are less common and may not be supported by all manufacturers.

-

How can I ensure my Gerber files are correct before sending them to a manufacturer?

- To ensure the accuracy of your Gerber files, use a Gerber viewer software to review and verify the design. Compare the viewed files with your original PCB design to check for any discrepancies or missing features. Additionally, consult with your manufacturer for their specific guidelines and requirements for Gerber file submission.

Conclusion

Gerber files play a crucial role in the PCB manufacturing process, serving as the standard format for conveying design information between designers and manufacturers. By creating accurate and complete Gerber files, you can ensure that your PCB is produced correctly and efficiently, minimizing the risk of errors and delays.

To optimize your PCB manufacturing experience, follow best practices for generating Gerber files, use reputable design software, and collaborate closely with your chosen manufacturer. By understanding the importance of Gerber files and their role in the production process, you can streamline your PCB projects and achieve high-quality results.

As PCB technology continues to evolve, staying informed about the latest Gerber file formats and industry standards will help you stay ahead of the curve and adapt to new design and manufacturing challenges. By mastering the art of Gerber files, you can unlock the full potential of your PCB designs and bring your electronic innovations to life.

Leave a Reply