Introduction

Printed Circuit Board (PCB) assembly is a critical process in the manufacturing of electronic devices. The success of the assembly process directly impacts the quality, reliability, and functionality of the final product. In this article, we will discuss the top 10 tips to ensure PCB Assembly success, covering various aspects such as design, component selection, surface mount technology (SMT), and quality control.

Tip 1: Design for Manufacturability (DFM)

Understanding DFM

Design for Manufacturability (DFM) is a crucial concept in PCB assembly. It involves designing the PCB in a way that optimizes the manufacturing process, reduces the risk of defects, and improves the overall quality of the final product.

Key DFM Considerations

| Aspect | Consideration |

|---|---|

| Footprint | Ensure component footprints are accurate and compatible with the manufacturing process |

| Spacing | Maintain appropriate spacing between components and traces to avoid short circuits |

| Orientation | Consider component orientation for ease of assembly and to minimize assembly errors |

| Panelization | Design the PCB to be panelized efficiently, maximizing the number of boards per panel |

Benefits of Implementing DFM

- Reduced manufacturing costs

- Improved product quality and reliability

- Faster time-to-market

- Fewer assembly defects and rework

Tip 2: Choose the Right Components

Component Selection Criteria

Selecting the right components is essential for successful PCB assembly. Consider the following criteria when choosing components:

- Functionality: Ensure the component meets the electrical and performance requirements of the design.

- Availability: Choose components that are readily available and have a reliable supply chain.

- Cost: Consider the cost of the component and its impact on the overall project budget.

- Package type: Select package types that are compatible with the chosen assembly process (e.g., SMT or through-hole).

Common Component Package Types

| Package Type | Description |

|---|---|

| SMD (Surface Mount Device) | Components mounted directly onto the PCB surface |

| Through-hole | Components with leads that are inserted into holes drilled in the PCB |

| BGA (Ball Grid Array) | High-density package with a grid of solder balls underneath the component |

| QFP (Quad Flat Package) | Surface-mounted package with leads on all four sides |

Component Traceability

Maintain proper component traceability throughout the assembly process by:

- Using unique part numbers for each component

- Keeping accurate records of component suppliers and lot numbers

- Implementing a robust inventory management system

Tip 3: Optimize Surface Mount Technology (SMT) Process

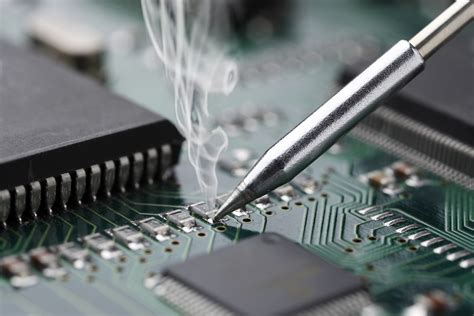

SMT Overview

Surface Mount Technology (SMT) is the most common PCB assembly method, involving the placement of components directly onto the surface of the PCB.

Key SMT Process Steps

- Solder Paste Printing: Applying solder paste onto the PCB pads using a stencil

- Component Placement: Placing components onto the solder paste using pick-and-place machines

- Reflow Soldering: Melting the solder paste in a reflow oven to form a permanent connection

Optimizing SMT Process Parameters

To ensure optimal SMT results, consider the following:

- Stencil thickness and aperture size

- Solder paste type and viscosity

- Pick-and-place machine accuracy and speed

- Reflow oven temperature profile and conveyor speed

Tip 4: Implement Effective Quality Control Measures

Importance of Quality Control

Implementing effective quality control measures is crucial for ensuring PCB assembly success. Quality control helps identify and prevent defects, reduce rework, and improve overall product reliability.

Common Quality Control Techniques

| Technique | Description |

|---|---|

| Visual Inspection | Manual or automated inspection of the PCB for visible defects |

| Automated Optical Inspection (AOI) | Using cameras and image processing to detect assembly defects |

| X-Ray Inspection | Non-destructive inspection of solder joints and internal components |

| Functional Testing | Verifying the electrical functionality of the assembled PCB |

Establishing Quality Control Checkpoints

Incorporate quality control checkpoints at critical stages of the assembly process:

- Incoming material inspection

- Post-solder paste printing inspection

- Post-component placement inspection

- Post-reflow soldering inspection

- Final functional testing

Tip 5: Use Appropriate Soldering Techniques

Soldering Methods

Two primary soldering methods are used in PCB assembly:

- Reflow Soldering: Used for SMT components, involving the application of solder paste and melting it in a reflow oven

- Wave Soldering: Used for through-hole components, involving the PCB passing over a molten solder wave

Soldering Process Considerations

To achieve reliable solder joints, consider the following:

- Solder alloy composition and melting temperature

- Flux type and activity level

- Preheat and cooling rates

- Soldering iron temperature and tip size (for manual soldering)

Preventing Soldering Defects

Common soldering defects and their prevention:

| Defect | Prevention |

|---|---|

| Bridging | Maintain appropriate spacing between pads and use proper solder paste volume |

| Cold Joint | Ensure adequate preheating and maintain proper soldering temperature |

| Tombstoning | Ensure even heating of component pads and use appropriate solder paste volume |

| Solder Balls | Optimize reflow profile and use solder paste with good tackiness |

Tip 6: Manage Electrostatic Discharge (ESD)

ESD Risks in PCB Assembly

Electrostatic Discharge (ESD) can damage sensitive electronic components during PCB assembly, leading to latent defects and reduced product reliability.

ESD Protection Measures

Implement the following ESD protection measures:

- Use ESD-safe workstations, including grounded mats and wrist straps

- Store and transport components in ESD-safe packaging

- Train personnel on ESD awareness and handling procedures

- Maintain a controlled environment with proper humidity levels

ESD Monitoring and Testing

Regularly monitor and test the effectiveness of ESD protection measures:

- Conduct periodic audits of ESD-safe workstations and equipment

- Perform ESD testing on assembled PCBs to detect potential ESD damage

- Investigate and address any ESD-related incidents promptly

Tip 7: Implement Traceability and Documentation

Importance of Traceability

Traceability in PCB assembly refers to the ability to track the history, application, and location of components and assemblies throughout the manufacturing process.

Benefits of Traceability

- Enables quick identification and isolation of defective components or batches

- Facilitates root cause analysis and corrective action implementation

- Enhances quality control and regulatory compliance

- Improves customer satisfaction by enabling efficient product recalls if necessary

Documentation Best Practices

Maintain comprehensive documentation throughout the PCB assembly process:

- Bill of Materials (BOM): List of all components used in the assembly

- Assembly Drawings: Detailed illustrations of component placement and orientation

- Work Instructions: Step-by-step guides for assembly procedures

- Quality Control Records: Inspection and testing results, defect data, and corrective actions

Tip 8: Foster Effective Communication and Collaboration

Importance of Communication

Effective communication and collaboration among all stakeholders are essential for successful PCB assembly projects.

Key Stakeholders

- Design Engineers

- Manufacturing Engineers

- Quality Control Personnel

- Procurement and Supply Chain Teams

- Customers and Suppliers

Communication Best Practices

Foster effective communication and collaboration through:

- Regular project meetings and status updates

- Clear and concise documentation, including specifications and requirements

- Timely feedback and issue resolution

- Cross-functional team involvement in design reviews and process improvements

Tip 9: Continuously Monitor and Improve Processes

Process Monitoring

Continuously monitor PCB assembly processes to identify areas for improvement and ensure consistent quality.

Key Process Metrics

| Metric | Description |

|---|---|

| First Pass Yield (FPY) | Percentage of PCBs that pass all quality inspections without rework |

| Defects Per Million Opportunities (DPMO) | Number of defects per million opportunities for defects to occur |

| Cycle Time | Time required to complete the assembly process for a single PCB |

| On-Time Delivery (OTD) | Percentage of orders delivered on or before the promised delivery date |

Continuous Improvement Initiatives

Implement continuous improvement initiatives to enhance PCB assembly processes:

- Conduct root cause analysis for recurring defects or issues

- Implement corrective and preventive actions (CAPA)

- Encourage employee suggestions and feedback for process improvements

- Benchmark against industry best practices and standards

Tip 10: Invest in Training and Skill Development

Importance of Skilled Personnel

Skilled and well-trained personnel are crucial for achieving PCB assembly success. Investing in training and skill development helps ensure that employees have the necessary knowledge and expertise to perform their tasks effectively.

Training Areas

Provide training in the following areas:

- PCB assembly techniques and best practices

- Quality control and inspection methods

- ESD protection and handling procedures

- Equipment operation and maintenance

- Problem-solving and troubleshooting skills

Training Methods

Implement a variety of training methods to cater to different learning styles:

- On-the-job training and mentoring

- Classroom-based training sessions

- Online courses and webinars

- Hands-on workshops and demonstrations

FAQ

1. What is the most critical factor in ensuring PCB assembly success?

The most critical factor in ensuring PCB assembly success is implementing a comprehensive approach that covers all aspects of the process, from design to quality control. This includes following Design for Manufacturability (DFM) principles, selecting the right components, optimizing the SMT process, implementing effective quality control measures, and continuously monitoring and improving processes.

2. How can I reduce the risk of ESD damage during PCB assembly?

To reduce the risk of ESD damage during PCB assembly, implement a comprehensive ESD protection program that includes the use of ESD-safe workstations, proper storage and transport of components, regular ESD testing, and employee training on ESD awareness and handling procedures.

3. What are the benefits of implementing traceability in PCB assembly?

Implementing traceability in PCB assembly offers several benefits, including the ability to quickly identify and isolate defective components or batches, facilitate root cause analysis and corrective action implementation, enhance quality control and regulatory compliance, and improve customer satisfaction by enabling efficient product recalls if necessary.

4. How can I ensure consistent quality in PCB assembly?

To ensure consistent quality in PCB assembly, implement a robust quality control system that includes visual inspection, automated optical inspection (AOI), X-ray inspection, and functional testing. Establish quality control checkpoints at critical stages of the assembly process, and continuously monitor key process metrics such as First Pass Yield (FPY) and Defects Per Million Opportunities (DPMO).

5. What role does training play in achieving PCB assembly success?

Training plays a crucial role in achieving PCB assembly success by ensuring that employees have the necessary knowledge and skills to perform their tasks effectively. Investing in training and skill development in areas such as PCB assembly techniques, quality control, ESD protection, and problem-solving helps improve overall process efficiency, reduce defects, and enhance product quality.

Conclusion

Achieving PCB assembly success requires a multi-faceted approach that encompasses design, component selection, process optimization, quality control, and continuous improvement. By following the top 10 tips discussed in this article, you can significantly enhance the quality, reliability, and efficiency of your PCB assembly processes. Remember to prioritize Design for Manufacturability (DFM), choose the right components, optimize the SMT process, implement effective quality control measures, and invest in training and skill development. With a commitment to best practices and continuous improvement, you can ensure the long-term success of your PCB assembly operations.

Leave a Reply