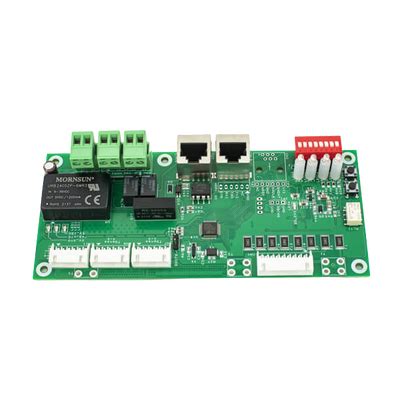

Introduction to PCB box-build Services

In the world of electronics manufacturing, PCB box-build services have become increasingly important. A PCB box-build is a comprehensive solution that involves the assembly of printed circuit boards (PCBs) and their integration into a complete product, including enclosures, wiring, and other components. This process streamlines the manufacturing process and ensures that the final product meets the required specifications and quality standards.

What are PCB Box-Build Services?

PCB box-build services encompass the entire process of assembling a complete electronic product from start to finish. This includes:

- PCB fabrication

- Component procurement

- PCB Assembly

- Enclosure fabrication

- Product integration

- Testing and quality control

By offering a complete PCB box-build service, manufacturers can provide their customers with a turnkey solution that saves time, reduces costs, and ensures product consistency.

Benefits of PCB Box-Build Services

There are numerous benefits to using PCB box-build services, including:

Cost Savings

Outsourcing PCB box-build services can result in significant cost savings compared to managing the process in-house. This is because PCB box-build providers have established relationships with component suppliers, allowing them to secure competitive pricing. Additionally, they have the necessary equipment and expertise to efficiently assemble and test products, reducing labor costs and minimizing waste.

Faster Time-to-Market

By leveraging the expertise and resources of a PCB box-build provider, companies can accelerate their product development and launch processes. The provider can handle the entire manufacturing process, from PCB fabrication to final product assembly, allowing the company to focus on other aspects of their business, such as marketing and sales.

Improved Quality and Reliability

PCB box-build providers have the knowledge and experience to ensure that products are assembled to the highest quality standards. They use state-of-the-art equipment and follow strict quality control procedures to minimize defects and ensure product reliability. This results in fewer returns, higher customer satisfaction, and a better overall reputation for the company.

Flexibility and Scalability

PCB box-build services offer flexibility and scalability to accommodate varying production volumes and product requirements. Providers can quickly ramp up or down production as needed, allowing companies to respond to changes in market demand without the need for significant capital investments in equipment and personnel.

Key Considerations for Choosing a PCB Box-Build Provider

When selecting a PCB box-build provider, there are several key factors to consider:

Technical Capabilities

Ensure that the provider has the technical capabilities to handle your specific product requirements. This includes experience with the relevant PCB technologies, component types, and assembly processes. The provider should also have the necessary certifications and quality management systems in place to ensure consistent results.

Manufacturing Capacity

Consider the provider’s manufacturing capacity and their ability to scale production to meet your needs. This includes the size of their facilities, the number of assembly lines, and their ability to handle both small and large production runs.

Supply Chain Management

A reliable PCB box-build provider should have a robust supply chain management system in place. This includes established relationships with component suppliers, the ability to source hard-to-find components, and the capability to manage inventory levels to ensure timely delivery.

Communication and Support

Effective communication and support are essential for a successful partnership with a PCB box-build provider. Look for a provider that offers clear lines of communication, regular project updates, and responsive customer support. They should also be willing to collaborate closely with your team to ensure that your product requirements are met.

The PCB Box-Build Process

The PCB box-build process typically involves the following steps:

-

Design and Engineering: The process begins with the design and engineering of the PCB and the overall product. This includes schematic design, PCB layout, component selection, and mechanical design of the enclosure.

-

Prototyping: Once the design is finalized, a prototype is created to validate the design and ensure that it meets the required specifications. This allows for any necessary changes to be made before moving into full production.

-

PCB Fabrication: The PCBs are fabricated according to the approved design. This involves creating the copper traces, drilling holes, and applying any necessary finishes or coatings.

-

Component Procurement: The required components are sourced from approved suppliers. The PCB box-build provider will manage the procurement process, ensuring that components are available when needed and that they meet the required quality standards.

-

PCB Assembly: The PCBs are assembled using automated equipment, such as pick-and-place machines and reflow ovens. This process involves placing components on the PCB and soldering them in place.

-

Enclosure Fabrication: The enclosure is fabricated according to the mechanical design. This may involve processes such as CNC machining, injection molding, or sheet metal fabrication.

-

Product Integration: The assembled PCBs are integrated into the enclosure, along with any necessary wiring, connectors, and other components. This process requires careful attention to detail to ensure proper fit and function.

-

Testing and Quality Control: The completed product undergoes rigorous testing and quality control procedures to ensure that it meets the required specifications and functions as intended. This may include functional testing, environmental testing, and burn-in testing.

-

Packaging and Shipping: Once the product has passed all quality control checks, it is packaged and shipped to the customer according to their requirements.

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity for PCB box-build services?

The minimum order quantity varies depending on the provider and the complexity of the product. Some providers may offer low-volume production runs for prototyping or small-scale production, while others may require larger minimum order quantities for full-scale production. -

How long does the PCB box-build process typically take?

The lead time for PCB box-build services depends on several factors, including the complexity of the product, the availability of components, and the production volume. Typical lead times can range from a few weeks to several months. It’s important to discuss your specific timeline requirements with your chosen provider to ensure that they can meet your needs. -

Can PCB box-build providers assist with product design and engineering?

Many PCB box-build providers offer design and engineering services to help customers optimize their products for manufacturability and performance. This can include assistance with PCB layout, component selection, and mechanical design. Some providers may also offer value-engineering services to help reduce costs and improve product reliability. -

How can I ensure that my intellectual property is protected when using a PCB box-build provider?

Protecting intellectual property is a critical concern when outsourcing PCB box-build services. To mitigate risks, choose a provider with a strong reputation for integrity and a track record of protecting customer IP. Ensure that your provider has appropriate security measures in place, such as access controls, confidentiality agreements, and secure data storage. It’s also important to establish clear communication channels and protocols for sharing sensitive information. -

What certifications should I look for when choosing a PCB box-build provider?

When selecting a PCB box-build provider, look for relevant certifications that demonstrate their commitment to quality and reliability. Some common certifications include: - ISO 9001 (Quality Management Systems)

- ISO 13485 (Medical Device Quality Management Systems)

- AS9100 (Aerospace Quality Management Systems)

- IPC-A-610 (Acceptability of Electronic Assemblies)

- IPC-J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies)

Providers with these certifications have demonstrated their ability to meet strict quality standards and industry best practices.

Conclusion

PCB box-build services offer a comprehensive solution for electronics manufacturing, providing benefits such as cost savings, faster time-to-market, improved quality and reliability, and flexibility and scalability. When choosing a PCB box-build provider, consider their technical capabilities, manufacturing capacity, supply chain management, and communication and support. By partnering with a reliable provider and understanding the PCB box-build process, companies can streamline their product development and manufacturing efforts, ultimately delivering high-quality products to their customers.

| Benefit | Description |

|---|---|

| Cost Savings | Outsourcing PCB box-build services can result in significant cost savings compared to managing the process in-house due to established supplier relationships and efficient assembly processes. |

| Faster Time-to-Market | PCB box-build providers can handle the entire manufacturing process, allowing companies to accelerate product development and launch. |

| Improved Quality and Reliability | Providers use state-of-the-art equipment and follow strict quality control procedures to minimize defects and ensure product reliability. |

| Flexibility and Scalability | PCB box-build services offer flexibility and scalability to accommodate varying production volumes and product requirements. |

By leveraging the expertise and resources of a PCB box-build provider, companies can focus on their core competencies while ensuring that their electronic products are manufactured to the highest standards. This approach enables businesses to remain competitive in today’s fast-paced and ever-evolving technology landscape.

Leave a Reply