What is PCB impedance matching?

PCB impedance matching is a crucial aspect of designing printed circuit boards (PCBs) to ensure optimal signal integrity and minimize signal reflections. It involves matching the impedance of the transmission lines on the PCB to the impedance of the source and load components. When the impedances are matched, maximum power transfer occurs, and signal reflections are minimized, resulting in improved signal quality and reduced electromagnetic interference (EMI).

Why is PCB Impedance Matching Important?

Impedance matching is essential in PCB design for several reasons:

-

Signal Integrity: Proper impedance matching ensures that signals propagate through the transmission lines without significant reflections or distortions. Mismatched impedances can lead to signal reflections, causing issues such as ringing, overshoot, and undershoot, which can degrade signal quality and cause errors in digital systems.

-

Power Transfer: When impedances are matched, maximum power is transferred from the source to the load. Mismatched impedances result in power being reflected back to the source, reducing the efficiency of power transfer and potentially causing damage to components.

-

EMI Reduction: Impedance mismatches can lead to increased electromagnetic radiation from the PCB, causing EMI issues. By properly matching impedances, the amount of radiated EMI can be minimized, helping to ensure compliance with electromagnetic compatibility (EMC) regulations.

Techniques for PCB Impedance Matching

There are several techniques used for impedance matching in PCB design. Here are some commonly used methods:

1. Controlled Impedance Traces

Controlled impedance traces are designed to have a specific characteristic impedance, typically 50 ohms or 100 ohms, depending on the application. The impedance of a trace is determined by factors such as the trace width, thickness, spacing, and the dielectric constant of the PCB material. By carefully designing the trace geometry and selecting appropriate PCB Materials, designers can achieve the desired characteristic impedance.

2. Termination Resistors

Termination resistors are used to match the impedance of the transmission line to the impedance of the source or load. By placing a resistor with a value equal to the characteristic impedance of the trace at the end of the transmission line, reflections can be minimized. There are different types of termination schemes, such as series termination, parallel termination, and Thevenin termination, each suitable for specific applications.

3. Stub Matching

Stub matching involves adding a short trace (stub) at the end of the transmission line to compensate for impedance mismatches. The length and width of the stub are carefully designed to provide the necessary impedance transformation. Stub matching is commonly used in high-frequency applications, such as RF and microwave circuits.

4. Tapered Transmission Lines

Tapered transmission lines are used to gradually change the impedance along the length of the trace. By gradually increasing or decreasing the trace width, the impedance can be matched to the desired value. Tapered transmission lines are useful in situations where impedance needs to be matched over a wide frequency range or when connecting traces with different characteristic impedances.

Zero Resistance Impedance Matching

Zero resistance impedance matching is a specific technique used to achieve impedance matching without the use of physical resistors. Instead, it relies on the design of the PCB Traces and the placement of components to create a virtual zero resistance point.

Advantages of Zero Resistance Impedance Matching

Zero resistance impedance matching offers several advantages over traditional impedance matching techniques:

-

Reduced Component Count: By eliminating the need for physical resistors, zero resistance impedance matching reduces the component count on the PCB. This can lead to cost savings, increased reliability, and simplified assembly.

-

Improved Signal Integrity: Zero resistance impedance matching minimizes the impact of resistor parasitics, such as capacitance and inductance, which can degrade signal quality at high frequencies. By eliminating physical resistors, the signal path remains clean and free from additional distortions.

-

Enhanced Power Efficiency: Traditional impedance matching techniques using resistors dissipate power as heat, reducing overall power efficiency. Zero resistance impedance matching eliminates this power dissipation, resulting in improved power efficiency and reduced heat generation.

Implementing Zero Resistance Impedance Matching

To implement zero resistance impedance matching, designers need to carefully consider the PCB layout and component placement. Here are some key steps:

-

Trace Length Matching: The lengths of the traces connecting the source, load, and zero resistance point should be carefully matched. This ensures that the signals arrive at the zero resistance point at the same time, creating a virtual ground.

-

Component Placement: The placement of components, such as capacitors and inductors, plays a crucial role in zero resistance impedance matching. These components are strategically placed to create the desired impedance transformation and to establish the zero resistance point.

-

Simulation and Optimization: Electromagnetic simulation tools are used to model and optimize the PCB layout for zero resistance impedance matching. These simulations help designers fine-tune the trace lengths, component values, and placement to achieve the desired impedance matching performance.

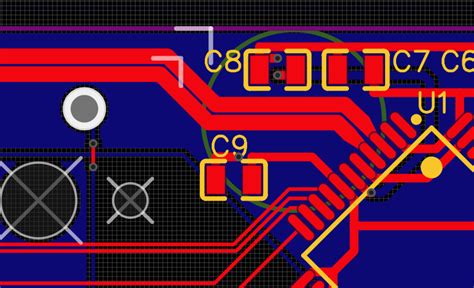

PCB Layout Considerations for Impedance Matching

Proper PCB layout is essential for successful impedance matching. Here are some key considerations:

1. Trace Width and Spacing

The width and spacing of PCB traces directly impact their characteristic impedance. Wider traces have lower impedance, while narrower traces have higher impedance. The spacing between traces also affects the impedance, as closely spaced traces exhibit higher coupling capacitance. Designers must carefully calculate and control trace widths and spacings to achieve the desired impedance.

2. Layer Stack-up

The layer stack-up of the PCB plays a significant role in impedance matching. The thickness and dielectric constant of the PCB Substrate Materials, as well as the arrangement of signal and ground layers, influence the characteristic impedance of the traces. Designers must select appropriate materials and optimize the layer stack-up to maintain consistent impedance throughout the board.

3. Via Design

Vias are used to connect traces between different layers of the PCB. However, vias introduce discontinuities in the signal path and can cause impedance mismatches. To minimize the impact of vias, designers can use techniques such as via shielding, via stitching, and optimizing via size and placement. Additionally, using blind and Buried Vias can help reduce the impact of vias on impedance matching.

4. Ground Plane Design

A solid ground plane is essential for maintaining a stable reference plane and controlling impedance. The ground plane should be continuous and uninterrupted, with minimal gaps or slots. Designers should also pay attention to the spacing between the ground plane and signal traces, as this affects the characteristic impedance. In some cases, using a power plane as a reference plane can also be beneficial for impedance matching.

Impedance Matching Challenges and Solutions

Impedance matching in PCB design can present various challenges. Here are some common challenges and potential solutions:

1. High-Frequency Signal Integrity

At high frequencies, signal integrity becomes more critical, and impedance mismatches can have a significant impact on signal quality. To address this challenge, designers can use advanced techniques such as differential signaling, edge-coupled traces, and high-speed materials with low dielectric loss. Additionally, using simulation tools to analyze and optimize the high-frequency performance of the PCB can help ensure proper impedance matching.

2. Impedance Discontinuities

Impedance discontinuities can occur due to various factors, such as trace bends, layer transitions, and component pad layouts. These discontinuities can cause reflections and degrade signal quality. To mitigate impedance discontinuities, designers can use techniques such as smooth trace bends, matched-length trace routing, and optimized component pad designs. Simulation tools can also help identify and address impedance discontinuities in the PCB layout.

3. Manufacturing Tolerances

Manufacturing tolerances can introduce variations in trace widths, spacings, and dielectric thicknesses, affecting the characteristic impedance of the traces. To account for manufacturing tolerances, designers can specify impedance tolerance requirements and work closely with PCB Fabricators to ensure tight control over the manufacturing process. Additionally, incorporating impedance testing and validation into the manufacturing process can help identify and correct any impedance deviations.

FAQ

1. What is the importance of impedance matching in PCB design?

Impedance matching is crucial in PCB design to ensure proper signal integrity, maximize power transfer, and minimize signal reflections and EMI. It helps to maintain signal quality, reduce errors, and ensure reliable operation of the electronic system.

2. What is the difference between controlled impedance traces and regular traces?

Controlled impedance traces are designed to have a specific characteristic impedance, typically 50 ohms or 100 ohms, by carefully controlling their width, thickness, spacing, and the dielectric constant of the PCB material. Regular traces, on the other hand, do not have a precisely controlled impedance and may exhibit impedance variations along their length.

3. What are the advantages of using zero resistance impedance matching?

Zero resistance impedance matching offers several advantages, including reduced component count, improved signal integrity, and enhanced power efficiency. By eliminating physical resistors, it minimizes the impact of resistor parasitics, simplifies assembly, and reduces power dissipation and heat generation.

4. How does the PCB layer stack-up affect impedance matching?

The PCB layer stack-up influences impedance matching by determining the thickness and dielectric constant of the substrate materials, as well as the arrangement of signal and ground layers. The layer stack-up affects the characteristic impedance of the traces and must be carefully designed to maintain consistent impedance throughout the board.

5. What are some common challenges in achieving impedance matching in PCB design?

Some common challenges in achieving impedance matching include maintaining signal integrity at high frequencies, dealing with impedance discontinuities due to trace bends and layer transitions, and accounting for manufacturing tolerances. These challenges can be addressed through advanced design techniques, simulation tools, and close collaboration with PCB fabricators to ensure tight control over the manufacturing process.

| Parameter | Impact on Impedance Matching |

|---|---|

| Trace Width | Wider traces have lower impedance |

| Trace Spacing | Closely spaced traces exhibit higher coupling capacitance |

| PCB Substrate Material | Dielectric constant affects characteristic impedance |

| Layer Stack-up | Arrangement of signal and ground layers affects impedance |

| Via Design | Vias introduce discontinuities and impedance mismatches |

| Ground Plane Design | Continuous ground plane maintains stable reference plane |

| High-Frequency Effects | Signal integrity becomes more critical at high frequencies |

| Manufacturing Tolerances | Variations in trace dimensions affect impedance |

By carefully considering these parameters and applying appropriate design techniques, PCB designers can achieve effective impedance matching and ensure optimal signal integrity in their designs.

Leave a Reply