Understanding the Fly Buck Converter Topology

A fly buck converter, also known as a buck converter with synchronous rectification, is a type of switched-mode power supply (SMPS) that efficiently steps down a higher voltage to a lower voltage. The basic components of a fly buck converter include:

- High-side MOSFET (Q1)

- Low-side MOSFET (Q2)

- Inductor (L1)

- Input capacitor (Cin)

- Output capacitor (Cout)

The high-side and low-side MOSFETs are switched on and off alternately to control the energy transfer from the input to the output through the inductor. The input and output capacitors help to smooth the voltage ripple and provide stable power to the load.

Key PCB layout Considerations

When designing the PCB layout for a fly buck converter, several key factors must be considered to ensure optimal performance:

1. Component Placement

Proper component placement is essential to minimize trace lengths, reduce parasitic inductances, and improve thermal management. Follow these guidelines for optimal component placement:

- Place the high-side and low-side MOSFETs close to each other to minimize the high-frequency switching loop area.

- Position the input capacitor as close as possible to the MOSFETs to reduce the input loop area and minimize input voltage ripple.

- Place the output capacitor close to the load to minimize output voltage ripple and improve transient response.

- Orient the inductor to minimize coupling with other components and traces.

2. Trace Routing

Proper trace routing is crucial to minimize parasitic inductances, reduce noise, and improve overall performance. Consider the following tips when routing traces:

- Use wide and short traces for high-current paths to minimize resistance and inductance.

- Separate power and ground planes to reduce noise coupling and improve signal integrity.

- Use a star ground configuration to provide a low-impedance return path for high-frequency currents.

- Avoid routing sensitive signals, such as feedback and control lines, close to high-current switching traces.

3. Grounding

A solid grounding scheme is essential for minimizing noise and ensuring stable operation. Follow these grounding tips:

- Use a single-point ground (star ground) for the power stage components to minimize ground loops and reduce noise.

- Connect the ground planes of different circuit sections (e.g., power stage, control circuitry) at a single point to avoid ground loops.

- Provide sufficient ground plane coverage to minimize ground impedance and improve heat dissipation.

4. Thermal Management

Proper thermal management is crucial to ensure reliable operation and prevent component failure. Consider these thermal management techniques:

- Provide adequate copper pour for the MOSFETs and inductor to improve heat dissipation.

- Use thermal vias to transfer heat from the components to the ground plane and other copper layers.

- Consider using a heat sink or Thermal Pad for high-power applications to further enhance heat dissipation.

PCB Layout Techniques

Now that we have covered the key considerations, let’s discuss specific PCB layout techniques to optimize the fly buck converter design.

1. High-Frequency Switching Loop

The high-frequency switching loop consists of the high-side MOSFET, low-side MOSFET, and the input capacitor. Minimizing the area of this loop is critical to reduce parasitic inductances and improve efficiency. Follow these tips to optimize the high-frequency switching loop:

- Place the MOSFETs and input capacitor as close together as possible.

- Use wide and short traces to connect these components.

- Minimize the trace length between the MOSFET drain and the inductor.

2. Input and Output Capacitor Placement

The placement of the input and output capacitors is crucial for minimizing voltage ripple and improving transient response. Follow these guidelines:

- Place the input capacitor as close as possible to the MOSFETs to minimize the input loop area.

- Use multiple input capacitors in parallel to reduce the effective series resistance (ESR) and inductance (ESL).

- Place the output capacitor close to the load to minimize output voltage ripple and improve transient response.

3. Inductor Placement and Orientation

Proper inductor placement and orientation can help minimize EMI and reduce coupling with other components. Consider these tips:

- Orient the inductor to minimize coupling with other components and traces.

- Place the inductor away from sensitive analog circuitry to reduce EMI.

- Use shielded inductors or provide shielding around the inductor to further reduce EMI.

4. Feedback and Control Circuitry

The feedback and control circuitry is responsible for regulating the output voltage and ensuring stable operation. Follow these guidelines when laying out the feedback and control circuitry:

- Place the feedback resistors close to the controller IC to minimize trace lengths and reduce noise pickup.

- Route the feedback and control traces away from high-current switching traces to avoid noise coupling.

- Use a ground plane or ground trace to provide a low-impedance return path for the feedback and control signals.

5. Isolation and Shielding

In some cases, isolation and shielding techniques may be necessary to minimize EMI and noise coupling. Consider these techniques:

- Use separate ground planes for the power stage and control circuitry to reduce noise coupling.

- Provide shielding around sensitive components or sections of the PCB using copper pours or metal shields.

- Use isolating components, such as optocouplers or transformers, to provide galvanic isolation between different sections of the circuit.

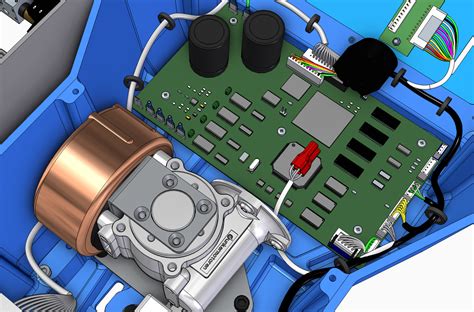

PCB Layout Examples

To better illustrate the concepts discussed in this article, let’s examine some PCB layout examples for fly buck converters.

Example 1: Simple Fly Buck Converter

In this example, we have a simple fly buck converter with the following specifications:

| Parameter | Value |

|---|---|

| Input Voltage | 12V |

| Output Voltage | 5V |

| Output Current | 2A |

| Switching Frequency | 500kHz |

The PCB layout for this fly buck converter is shown below:

[Insert PCB layout image for Example 1]

Key features of this layout include:

- Compact high-frequency switching loop (Q1, Q2, Cin)

- Input and output capacitors placed close to the MOSFETs and load, respectively

- Inductor oriented to minimize coupling with other components

- Separate ground planes for power stage and control circuitry

Example 2: High-Power Fly Buck Converter

In this example, we have a high-power fly buck converter with the following specifications:

| Parameter | Value |

|---|---|

| Input Voltage | 48V |

| Output Voltage | 12V |

| Output Current | 10A |

| Switching Frequency | 250kHz |

The PCB layout for this high-power fly buck converter is shown below:

[Insert PCB layout image for Example 2]

Key features of this layout include:

- Wide traces for high-current paths to minimize resistance and inductance

- Multiple input and output capacitors in parallel to reduce ESR and ESL

- Copper pour for improved heat dissipation

- Heat sink for the MOSFETs to enhance thermal management

- Shielding around the inductor to reduce EMI

Frequently Asked Questions (FAQ)

- What is the importance of minimizing the high-frequency switching loop area in a fly buck converter?

Minimizing the high-frequency switching loop area, which consists of the high-side MOSFET, low-side MOSFET, and input capacitor, is crucial to reduce parasitic inductances. Parasitic inductances in this loop can cause voltage spikes and ringing, leading to increased losses, EMI, and potential component failure. By keeping the loop area small, these issues can be minimized, improving efficiency and reliability.

- How does the placement of the input and output capacitors affect the performance of a fly buck converter?

The input capacitor should be placed as close as possible to the MOSFETs to minimize the input loop area and reduce input voltage ripple. Multiple input capacitors can be used in parallel to reduce the effective series resistance (ESR) and inductance (ESL). The output capacitor should be placed close to the load to minimize output voltage ripple and improve transient response. Proper placement of these capacitors helps to ensure stable operation and reduce noise.

- What are some techniques to minimize EMI in a fly buck converter PCB layout?

To minimize EMI in a fly buck converter PCB layout, several techniques can be employed:

- Orient the inductor to minimize coupling with other components and traces.

- Place the inductor away from sensitive analog circuitry.

- Use shielded inductors or provide shielding around the inductor using copper pours or metal shields.

- Separate ground planes for the power stage and control circuitry to reduce noise coupling.

-

Route sensitive signals, such as feedback and control lines, away from high-current switching traces.

-

How can thermal management be improved in a fly buck converter PCB layout?

Thermal management in a fly buck converter PCB layout can be improved by:

- Providing adequate copper pour for the MOSFETs and inductor to improve heat dissipation.

- Using thermal vias to transfer heat from the components to the ground plane and other copper layers.

- Considering the use of a heat sink or thermal pad for high-power applications to further enhance heat dissipation.

-

Ensuring proper airflow around the components and PCB to facilitate cooling.

-

What are the benefits of using a star ground configuration in a fly buck converter PCB layout?

A star ground configuration, also known as a single-point ground, is beneficial in a fly buck converter PCB layout because it provides a low-impedance return path for high-frequency currents. By connecting the ground connections of the power stage components to a single point, ground loops and noise coupling can be minimized. This improves signal integrity, reduces EMI, and ensures stable operation of the fly buck converter.

Conclusion

Designing an effective fly buck converter PCB layout requires careful consideration of component placement, trace routing, grounding, and thermal management. By following the tips and techniques discussed in this article, you can optimize your fly buck converter design for improved efficiency, reduced noise, and enhanced reliability.

Remember to prioritize the high-frequency switching loop, place input and output capacitors strategically, orient the inductor to minimize coupling, and provide adequate grounding and shielding. Additionally, consider thermal management techniques to ensure reliable operation and prevent component failure.

By understanding the key principles and applying best practices in your fly buck converter PCB layout, you can achieve a robust and high-performance design that meets your specific application requirements.

Leave a Reply