Understanding Board Thickness

Definition of Board Thickness

Board thickness refers to the measurement of a board’s depth or the distance between its two main faces. It is typically expressed in inches or millimeters, depending on the unit of measurement used in the specific industry or region.

Measuring Board Thickness

To accurately measure board thickness, you can use various tools, such as:

- Calipers: Digital or analog calipers provide precise measurements of board thickness.

- Micrometers: These tools offer highly accurate measurements and are commonly used in industries that require strict tolerances.

- Rulers or tape measures: While not as precise as calipers or micrometers, rulers and tape measures can provide a quick estimation of board thickness.

Factors Affecting Board Thickness

Several factors can influence the thickness of a board, including:

- Material properties: Different materials have varying densities and characteristics that affect their thickness.

- Manufacturing process: The method used to produce the board, such as sawing, planing, or extrusion, can impact its final thickness.

- Industry standards: Some industries have established thickness standards for specific applications to ensure consistency and compatibility.

Board Thickness in Different Materials

Wood

In woodworking and construction, board thickness is a crucial consideration. Common wood board thicknesses include:

| Nominal Thickness (inches) | Actual Thickness (inches) | Nominal Thickness (mm) | Actual Thickness (mm) |

|---|---|---|---|

| 1/4 | 0.25 | 6.35 | 6.35 |

| 1/2 | 0.50 | 12.7 | 12.7 |

| 3/4 | 0.75 | 19.05 | 19.05 |

| 1 | 0.94 | 25.4 | 23.8 |

Metal

Metal sheets and plates come in various thicknesses, depending on the specific alloy and application. Some common metal thickness measurements include:

| Gauge | Inches | Millimeters |

|---|---|---|

| 10 | 0.1345 | 3.416 |

| 12 | 0.1046 | 2.656 |

| 14 | 0.0747 | 1.897 |

| 16 | 0.0598 | 1.518 |

Plastic

Plastic sheets and boards are available in a wide range of thicknesses to suit different applications. Common plastic board thicknesses include:

| Inches | Millimeters |

|---|---|

| 1/16 | 1.5875 |

| 1/8 | 3.175 |

| 1/4 | 6.35 |

| 1/2 | 12.7 |

Importance of Board Thickness in Various Industries

Construction

In the construction industry, board thickness plays a vital role in ensuring the structural integrity and safety of buildings. For example:

- Subflooring: The thickness of subflooring boards affects their ability to support the weight of the flooring material and furniture.

- Sheathing: The thickness of wall and roof sheathing influences its resistance to wind, moisture, and other environmental factors.

- Framing lumber: The thickness of framing lumber, such as studs and joists, determines its load-bearing capacity and overall strength.

Woodworking

In woodworking, board thickness is essential for creating functional and aesthetically pleasing projects. Consider the following:

- Furniture making: The thickness of boards used in furniture affects its durability, stability, and visual appeal.

- Cabinetry: The thickness of cabinet components, such as shelves and doors, impacts their strength and resistance to warping.

- Decorative elements: The thickness of boards used for trim, molding, and other decorative features can influence the overall look and feel of a space.

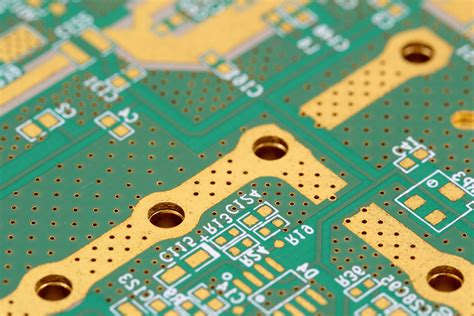

Electronics

In the electronics industry, board thickness is crucial for the proper functioning and reliability of electronic devices. For instance:

- Printed circuit boards (PCBs): The thickness of PCBs affects their mechanical strength, heat dissipation, and electrical properties.

- Insulation materials: The thickness of insulating boards, such as those made from fiberglass or ceramic, influences their ability to protect electronic components from heat and electrical interference.

- Enclosures: The thickness of boards used in electronic enclosures, such as device cases or Control Panels, impacts their durability and resistance to damage.

Choosing the Right Board Thickness

Factors to Consider

When selecting the appropriate board thickness for a specific application, consider the following factors:

- Strength and durability requirements: Assess the load-bearing capacity and environmental conditions the board will be exposed to.

- Weight considerations: Thicker boards are generally heavier, which may be a concern for certain applications.

- Cost: Thicker boards often come at a higher price point, so it’s essential to balance performance requirements with budget constraints.

- Aesthetic preferences: In some cases, the visual appeal of the board thickness may be a deciding factor, particularly in woodworking and interior design.

Industry Standards and Guidelines

Many industries have established standards and guidelines for board thickness to ensure consistency and quality. Some examples include:

- Building codes: Local building codes may specify minimum board thicknesses for various construction applications to ensure safety and compliance.

- Product certifications: Certain product certifications, such as those related to fire resistance or environmental sustainability, may have specific requirements for board thickness.

- Industry associations: Professional organizations, such as the American Wood Council or the Electronic Industries Alliance, may provide recommendations for board thickness based on best practices and industry research.

Frequently Asked Questions (FAQ)

1. Can I use a thinner board than recommended for my project?

While it may be tempting to use a thinner board to save on cost or weight, it’s essential to adhere to the recommended thickness for your specific application. Using a board that is too thin can compromise the strength, durability, and overall performance of your project.

2. How do I know which board thickness is right for my project?

To determine the appropriate board thickness for your project, consider factors such as the intended use, load-bearing requirements, environmental conditions, and industry standards. Consult with professionals, refer to manufacturer guidelines, and review relevant building codes or certifications to make an informed decision.

3. Can I laminate multiple thin boards to achieve the desired thickness?

In some cases, laminating multiple thinner boards together can be a viable option to achieve the desired thickness. However, it’s crucial to ensure proper adhesion and alignment of the boards to maintain structural integrity. Keep in mind that laminated boards may not perform identically to solid boards of the same thickness.

4. Are there any disadvantages to using thicker boards?

While thicker boards offer increased strength and durability, they also come with some drawbacks. Thicker boards are typically heavier, which can be a concern for weight-sensitive applications. They may also be more expensive and require more material, resulting in higher costs. Additionally, thicker boards may be more challenging to work with and may require specialized tools or techniques.

5. How does board thickness affect the final appearance of my project?

Board thickness can have a significant impact on the visual appeal of your project. In woodworking and interior design, the thickness of boards can contribute to the overall aesthetic, creating a sense of substance or delicacy. Thicker boards may convey a more robust and substantial look, while thinner boards can provide a sleek and modern appearance. Consider the desired aesthetic when choosing board thickness for your project.

Conclusion

Board thickness is a critical factor to consider when selecting materials for various applications across industries such as construction, woodworking, and electronics. Understanding the importance of board thickness and how it affects the strength, durability, and performance of your project is essential for making informed decisions.

By considering factors such as material properties, industry standards, and specific project requirements, you can choose the appropriate board thickness to ensure the success and longevity of your endeavors. Whether you’re building a house, crafting a piece of furniture, or designing an electronic device, paying attention to board thickness will contribute to the overall quality and functionality of your work.

Leave a Reply