Introduction to PCB Legends

A printed circuit board (PCB) legend, also known as silkscreen, is the layer of text and symbols printed on the surface of a PCB. The legend provides essential information for assembling, testing, and servicing the board. It includes component identifiers, polarity markers, test points, and other important details that help technicians and engineers understand the layout and function of the board.

The Importance of PCB Legends

PCB legends play a crucial role in the manufacturing process and throughout the lifecycle of a PCB. They enable:

- Efficient assembly

- Accurate testing and debugging

- Easier maintenance and repairs

- Better communication among team members

Without a clear and well-designed legend, a PCB can be difficult to work with, leading to errors, delays, and increased costs.

Elements of a PCB Legend

A typical PCB legend includes several key elements:

Component Identifiers

Each component on the board is labeled with a unique identifier, such as R1 for the first resistor, C2 for the second capacitor, and so on. These identifiers match those used in the schematic diagram and bill of materials (BOM), making it easy to locate and reference specific components.

Polarity Markers

Components like electrolytic capacitors, diodes, and LEDs have specific polarity requirements. The legend includes symbols like plus signs or bands to indicate the correct orientation of these components.

Test Points

Test points are labeled on the legend to facilitate testing and debugging. They may be marked with labels like TP1, TP2, or with more descriptive names like VCC, GND, or RESET.

Pin Numbers

For components with multiple pins, such as integrated circuits (ICs) and connectors, the legend labels each pin with its corresponding number. This information is essential for proper assembly and troubleshooting.

Text and Notes

Additional text and notes may be included on the legend to provide assembly instructions, warnings, or other relevant information. For example, “MOUNT ON BOTTOM SIDE” or “DO NOT POPULATE.”

Designing a PCB Legend

Creating a clear and effective PCB legend requires careful planning and attention to detail. Here are some best practices to follow:

Choose an Appropriate Font

Use a simple, legible font that remains clear even at small sizes. Some popular choices include:

- Arial

- Helvetica

- Verdana

- OCR-A

Avoid ornate or decorative fonts that may be difficult to read.

Use Appropriate Text Sizes

Ensure that text is large enough to be easily read but not so large that it clutters the board. A general guideline is to use a minimum text height of 0.8mm (0.032″) for primary component identifiers and 0.5mm (0.020″) for secondary information.

Position Text Thoughtfully

Place text near the components it refers to, but avoid overlapping with pads or traces. Orient text to be easily read from the same direction, typically from left to right or bottom to top.

Use Clear Symbols

For polarity markers and other symbols, use simple, standardized shapes that are easy to recognize. Avoid ambiguous or confusing symbols.

Provide Sufficient Clearance

Ensure adequate clearance between the legend and other board elements, such as copper traces and solder mask openings. This helps prevent short circuits and improves the legibility of the legend.

PCB Legend Manufacturing Process

PCB legends are typically applied using one of two methods: silkscreen printing or direct legend printing.

Silkscreen Printing

Silkscreen printing is the most common method for applying PCB legends. It involves:

- Creating a stencil with the legend artwork

- Placing the stencil over the PCB

- Forcing ink through the stencil openings onto the board surface

- Curing the ink to create a permanent legend

Silkscreen printing produces durable, high-contrast legends but requires additional setup time and materials.

Direct Legend Printing

Direct legend printing uses inkjet or laser technology to print the legend directly onto the PCB surface. This method offers several advantages:

- Faster setup and turnaround times

- Lower cost for small batches or prototypes

- Ability to print finer details and more complex artwork

However, direct legend printing may not be as durable as silkscreen printing and may have limitations in terms of color options.

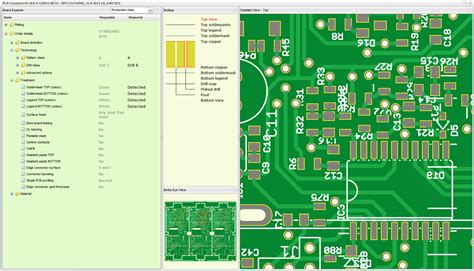

PCB Legend Design Software

Many PCB design software packages include tools for creating and managing PCB legends. Some popular options are:

| Software | Vendor | Legend Features |

|---|---|---|

| Altium | Altium | Integrated legend design and management |

| Eagle | Autodesk | Customizable legend templates |

| KiCad | KiCad | Open-source legend design tools |

| OrCAD | Cadence | Automated legend generation and placement |

| PADS | Mentor | Comprehensive legend design capabilities |

These software tools streamline the legend design process, ensuring consistency and adherence to design rules.

FAQ

1. What is the difference between a PCB legend and a silkscreen?

There is no difference between a PCB legend and a silkscreen. The terms are used interchangeably to refer to the layer of text and symbols printed on the surface of a PCB.

2. Can PCB legends be printed in colors other than white?

Yes, PCB legends can be printed in various colors, including black, yellow, and red. However, white is the most common color choice for its high contrast and legibility.

3. Are there any industry standards for PCB legend design?

While there are no universal standards for PCB legend design, many companies and organizations have developed their own internal guidelines. The IPC (Association Connecting Electronics Industries) offers some general recommendations in its IPC-7351B standard.

4. Can PCB legends be modified after manufacturing?

Modifying a PCB legend after manufacturing is possible but not recommended. It typically involves removing the existing legend with solvents and applying a new one, which can be time-consuming and risk damaging the board. It’s best to ensure the legend is correct before manufacturing.

5. What factors affect the cost of adding a legend to a PCB?

The cost of adding a legend to a PCB depends on several factors, including:

- The size and complexity of the legend artwork

- The manufacturing method (silkscreen vs. direct printing)

- The number of colors used

- The quantity of boards being produced

In general, simpler legends and larger production runs will result in lower per-board costs.

Conclusion

PCB legends are a critical element of PCB design and manufacturing, providing vital information for assembly, testing, and maintenance. By understanding the key elements of a legend and following best practices for design and manufacturing, engineers and technicians can create clear, effective legends that contribute to the overall success of a PCB project.

As PCB technologies continue to advance, the importance of well-designed legends will only grow. By staying current with industry trends and leveraging the latest design software and manufacturing techniques, professionals can ensure their PCB legends meet the evolving needs of the electronics industry.

Leave a Reply