What is an Outer Annular Ring?

An Outer Annular Ring is a circular component that is typically made of metal or composite materials. It is designed to fit around a shaft or bearing, providing support and reducing friction. OARs are commonly used in rotary systems, such as turbines, pumps, and engines, where they help to maintain proper alignment and minimize wear and tear.

Construction and Materials

OARs are typically constructed from high-strength materials that can withstand the rigors of continuous operation. Some common materials used in the manufacturing of OARs include:

-

Stainless Steel: Known for its durability and resistance to corrosion, stainless steel is a popular choice for OARs in demanding environments.

-

Aluminum: Lightweight and cost-effective, aluminum OARs are often used in applications where weight reduction is a priority.

-

Titanium: With its exceptional strength-to-weight ratio and corrosion resistance, titanium is an ideal material for OARs in high-performance applications.

-

Composites: Advanced composite materials, such as carbon fiber and Kevlar, are increasingly being used in the production of OARs due to their high strength, low weight, and excellent wear resistance.

| Material | Advantages | Disadvantages |

|---|---|---|

| Stainless Steel | Durable, corrosion-resistant | Heavy, expensive |

| Aluminum | Lightweight, cost-effective | Lower strength compared to steel |

| Titanium | High strength-to-weight ratio, corrosion-resistant | Expensive, difficult to machine |

| Composites | High strength, low weight, wear-resistant | High cost, complex manufacturing |

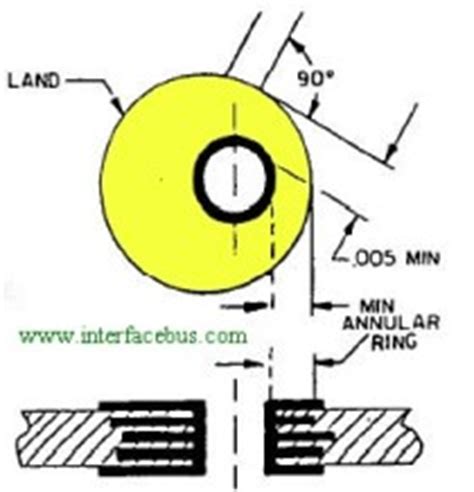

Design and Dimensions

The design and dimensions of an OAR vary depending on the specific application and the size of the shaft or bearing it will be fitted around. Some key design considerations include:

-

Inner Diameter: The inner diameter of the OAR must be precisely matched to the outer diameter of the shaft or bearing to ensure a tight, secure fit.

-

Outer Diameter: The outer diameter of the OAR is determined by the space available in the system and the required strength and rigidity.

-

Thickness: The thickness of the OAR wall is a critical factor in its overall strength and durability. Thicker walls provide greater support and resistance to deformation, but also increase weight and cost.

-

Surface Finish: The surface finish of the OAR can affect its performance and longevity. A smooth, polished surface helps to reduce friction and wear, while a textured surface may be used to improve grip and prevent slippage.

Applications of Outer Annular Rings

OARs are used in a wide range of industries and applications, including:

Aerospace

In the aerospace industry, OARs are used in various components of aircraft engines, such as turbines, compressors, and gearboxes. They help to maintain proper alignment, reduce vibration, and extend the lifespan of these critical systems.

Jet Engines

OARs play a crucial role in the operation of jet engines, particularly in the high-pressure turbine (HPT) section. The HPT is subjected to extreme temperatures and pressures, and the OARs help to maintain the proper alignment of the turbine blades and minimize friction between the rotating and stationary components.

Helicopters

In helicopters, OARs are used in the main rotor system, where they help to support the rotor blades and transmit the rotational force from the engine to the blades. The OARs in helicopters are typically made of high-strength materials, such as titanium or stainless steel, to withstand the high loads and vibrations encountered during flight.

Automotive

In the automotive industry, OARs are used in various components of the engine and transmission system, such as:

-

Crankshaft: OARs are used to support the crankshaft and reduce friction between the crankshaft and the engine block.

-

Camshaft: OARs are used to support the camshaft and maintain proper alignment, ensuring smooth operation of the valvetrain.

-

Transmission: OARs are used in the transmission system to support the gears and bearings, reducing friction and wear.

Industrial Machinery

OARs are also widely used in industrial machinery, such as:

-

Pumps: OARs are used in various types of pumps, including centrifugal and positive displacement pumps, to support the rotating components and reduce friction.

-

Compressors: OARs are used in compressors to support the rotating shafts and maintain proper alignment, ensuring efficient and reliable operation.

-

Turbines: OARs are used in steam and gas turbines to support the rotating components and minimize friction, extending the lifespan of these critical systems.

Advantages of Outer Annular Rings

OARs offer several key advantages over other types of support and alignment components, including:

-

Reduced Friction: The smooth, precision-machined surface of an OAR helps to reduce friction between the rotating and stationary components, improving efficiency and extending the lifespan of the system.

-

Improved Alignment: OARs help to maintain proper alignment of the rotating components, reducing vibration and wear, and ensuring smooth, reliable operation.

-

Increased Durability: The high-strength materials and robust construction of OARs make them highly durable and resistant to wear and tear, even in demanding operating conditions.

-

Versatility: OARs can be customized to fit a wide range of shaft and bearing sizes, making them suitable for use in a variety of industries and applications.

Maintenance and Replacement

To ensure optimal performance and longevity, OARs require regular maintenance and, eventually, replacement. Some key maintenance and replacement considerations include:

Inspection

Regular visual inspections of OARs should be conducted to check for signs of wear, damage, or corrosion. Any issues should be addressed promptly to prevent further damage and ensure safe, reliable operation.

Lubrication

Proper lubrication is essential for the smooth operation and longevity of OARs. The type and frequency of lubrication will depend on the specific application and operating conditions, but generally, a high-quality, high-temperature grease or oil should be used.

Replacement

Over time, even with proper maintenance, OARs will eventually wear out and require replacement. The lifespan of an OAR will depend on various factors, such as the material, operating conditions, and maintenance schedule. When replacing an OAR, it is crucial to use a high-quality, OEM-specified component to ensure optimal performance and compatibility.

Frequently Asked Questions (FAQ)

-

What is the purpose of an Outer Annular Ring (OAR)?

An OAR is designed to provide support and reduce friction between rotating and stationary components in mechanical systems, such as engines, turbines, and pumps. -

What materials are commonly used in the construction of OARs?

OARs are typically made of high-strength materials, such as stainless steel, aluminum, titanium, and advanced composites, depending on the specific application and operating conditions. -

How do I know when an OAR needs to be replaced?

Signs that an OAR may need replacement include visible wear or damage, increased vibration or noise, and reduced system efficiency. Regular inspections and adherence to the manufacturer’s recommended maintenance schedule can help identify when an OAR needs to be replaced. -

Can I use a different material when replacing an OAR?

It is generally recommended to use the same material as the original OAR or an OEM-specified alternative to ensure optimal performance and compatibility. Changing materials without proper engineering analysis and testing could result in reduced performance or premature failure. -

How can I extend the lifespan of an OAR?

Regular maintenance, including visual inspections and proper lubrication, can help extend the lifespan of an OAR. Operating the system within the manufacturer’s recommended parameters and avoiding overloading or excessive vibration can also help to maximize the life of the OAR.

Conclusion

The Outer Annular Ring is a critical component in many mechanical systems, providing essential support and reducing friction between rotating and stationary components. With a wide range of applications spanning the aerospace, automotive, and industrial sectors, OARs play a vital role in ensuring the smooth, reliable operation of machinery and equipment.

By understanding the construction, materials, and design considerations of OARs, as well as their applications, advantages, and maintenance requirements, engineers and technicians can make informed decisions when specifying, installing, and maintaining these critical components.

As technology continues to advance, it is likely that new materials and manufacturing techniques will be developed to further enhance the performance and durability of OARs, enabling even greater efficiency and reliability in the mechanical systems of the future.

Leave a Reply