Introduction to PCB Surface Finish

Printed Circuit Boards (PCBs) are essential components in modern electronics. They provide a platform for electrical components to be connected and mounted, enabling the creation of complex circuits. One crucial aspect of PCB design is selecting the appropriate surface finish. The surface finish not only protects the copper traces on the PCB but also plays a vital role in ensuring reliable soldering and long-term performance. In this article, we will explore the various PCB surface finish options available and guide you through the process of selecting the right one for your specific application.

Why is PCB Surface Finish Important?

Before diving into the different types of surface finishes, let’s understand why they are essential. The primary purposes of a PCB surface finish are:

-

Protection: The surface finish acts as a barrier, protecting the copper traces from oxidation and corrosion. Without a proper surface finish, the exposed copper would quickly degrade, leading to reduced conductivity and potential circuit failure.

-

Solderability: Surface finishes provide a solderable layer that allows components to be easily attached to the PCB using solder. Different surface finishes have varying levels of solderability, affecting the ease and reliability of the soldering process.

-

Enhancing Electrical Performance: Some surface finishes, such as immersion silver and electroless nickel immersion gold (ENIG), offer improved electrical conductivity compared to bare copper. This can be beneficial in high-frequency applications or situations where signal integrity is critical.

-

Aesthetics: While not the primary concern, surface finishes can also impact the visual appearance of the PCB. Some finishes, like ENIG, provide a attractive golden color, which may be desirable for certain applications.

Common Types of PCB Surface Finishes

There are several PCB surface finish options available, each with its own advantages and disadvantages. Let’s explore some of the most common types:

1. Hot Air Solder Leveling (HASL)

HASL is one of the most widely used surface finishes in the PCB industry. The process involves dipping the PCB into a molten solder bath and then using hot air to level the solder on the surface. The resulting finish provides excellent solderability and is relatively inexpensive.

Advantages:

– Cost-effective

– Good solderability

– Suitable for most general-purpose applications

Disadvantages:

– Inconsistent surface flatness due to the manual leveling process

– Not suitable for fine-pitch components

– Limited shelf life due to the possibility of solder oxidation

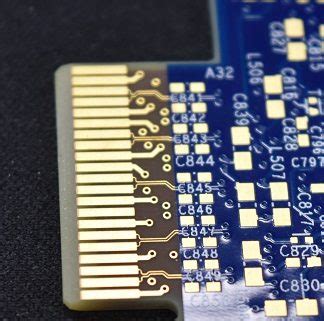

2. Electroless Nickel Immersion Gold (ENIG)

ENIG is a popular choice for high-reliability applications. The process involves depositing a layer of nickel onto the copper traces, followed by a thin layer of gold. The nickel layer provides a diffusion barrier, while the gold layer offers excellent solderability and protection against oxidation.

Advantages:

– Excellent solderability

– Long shelf life

– Suitable for fine-pitch components

– Good electrical conductivity

Disadvantages:

– Higher cost compared to HASL

– Potential for “black pad” defects due to improper plating processes

– Not suitable for press-fit connectors

3. Immersion Silver (IAg)

Immersion silver is a cost-effective alternative to ENIG. It involves depositing a thin layer of silver directly onto the copper traces. Silver offers excellent solderability and conductivity, making it suitable for high-frequency applications.

Advantages:

– Cost-effective compared to ENIG

– Excellent solderability

– Good electrical conductivity

– Suitable for fine-pitch components

Disadvantages:

– Limited shelf life due to silver tarnishing over time

– Not suitable for environments with high sulfur content

– Potential for silver migration in high-humidity conditions

4. Immersion Tin (ISn)

Immersion tin is another cost-effective surface finish option. It involves depositing a thin layer of tin onto the copper traces. Tin provides good solderability and is compatible with lead-free soldering processes.

Advantages:

– Cost-effective

– Good solderability

– Compatible with lead-free soldering

– Suitable for fine-pitch components

Disadvantages:

– Limited shelf life due to Tin Whiskers formation

– Not suitable for high-temperature applications

– Potential for tin pest formation in cold environments

5. Organic Solderability Preservative (OSP)

OSP is a chemical coating applied to the copper traces to prevent oxidation. It is a cost-effective and environmentally friendly option, as it does not involve any metal plating.

Advantages:

– Cost-effective

– Environmentally friendly

– Suitable for fine-pitch components

– Good solderability

Disadvantages:

– Limited shelf life due to the organic nature of the coating

– Not suitable for multiple soldering cycles

– Potential for inconsistent coating thickness

Factors to Consider When Selecting a PCB Surface Finish

When choosing a surface finish for your PCB, consider the following factors:

-

Application Requirements: Consider the specific requirements of your application, such as operating environment, temperature range, and expected lifespan. Some surface finishes may be more suitable for harsh environments or high-reliability applications.

-

Component Compatibility: Ensure that the chosen surface finish is compatible with the components you plan to use. Fine-pitch components may require a flatter surface finish, such as ENIG or immersion silver.

-

Soldering Process: Consider the soldering process you will be using. Some surface finishes, like HASL, may not be suitable for certain soldering techniques, such as reflow soldering.

-

Cost: Surface finish can impact the overall cost of the PCB. HASL is generally the most cost-effective option, while ENIG and immersion silver are more expensive.

-

Shelf Life: If your PCBs will be stored for an extended period before assembly, consider a surface finish with a longer shelf life, such as ENIG or immersion silver.

-

Electrical Performance: For high-frequency or signal-integrity-critical applications, consider surface finishes with better electrical conductivity, such as immersion silver or ENIG.

Comparison of PCB Surface Finishes

To help you make an informed decision, let’s compare the key characteristics of the common PCB surface finishes:

| Surface Finish | Solderability | Shelf Life | Fine-Pitch Compatibility | Cost |

|---|---|---|---|---|

| HASL | Good | Limited | Not suitable | Low |

| ENIG | Excellent | Long | Suitable | High |

| Immersion Silver | Excellent | Limited | Suitable | Moderate |

| Immersion Tin | Good | Limited | Suitable | Low |

| OSP | Good | Limited | Suitable | Low |

Frequently Asked Questions (FAQ)

-

Q: Can I mix different surface finishes on the same PCB?

A: While it is possible to use different surface finishes on the same PCB, it is generally not recommended. Mixing surface finishes can lead to compatibility issues and make the assembly process more challenging. It is best to choose a single surface finish that meets your requirements. -

Q: How does the surface finish affect the soldering process?

A: The surface finish plays a crucial role in the soldering process. It determines the solderability of the PCB and affects the wetting and spreading of the solder. A good surface finish ensures reliable solder joints and minimizes soldering defects. -

Q: Can I change the surface finish on an existing PCB design?

A: Yes, you can change the surface finish on an existing PCB design. However, it is essential to consider the compatibility of the new surface finish with the existing components and the soldering process. Changing the surface finish may require adjustments to the assembly process and component selection. -

Q: How does the surface finish impact the PCB’s long-term reliability?

A: The surface finish protects the copper traces from oxidation and corrosion, which can affect the PCB’s long-term reliability. A good surface finish, such as ENIG or immersion silver, provides excellent protection and enhances the PCB’s lifespan. However, factors like the operating environment and storage conditions also play a role in the PCB’s long-term reliability. -

Q: What is the most cost-effective surface finish option?

A: HASL (Hot Air Solder Leveling) is generally the most cost-effective surface finish option. It provides good solderability and is suitable for most general-purpose applications. However, it may not be the best choice for fine-pitch components or high-reliability applications. When considering cost, it is essential to balance it with the specific requirements of your project.

Conclusion

Selecting the right surface finish for your PCB is crucial for ensuring reliable soldering, long-term performance, and protection against oxidation and corrosion. By understanding the different types of surface finishes available and considering factors such as application requirements, component compatibility, soldering process, cost, shelf life, and electrical performance, you can make an informed decision that suits your specific needs.

Remember, each surface finish has its own advantages and disadvantages, and there is no one-size-fits-all solution. It is essential to evaluate your project requirements and consult with your PCB manufacturer to determine the most appropriate surface finish for your application.

By choosing the right PCB surface finish, you can enhance the reliability, longevity, and performance of your electronic devices. Take the time to carefully consider your options and make a well-informed decision to ensure the success of your PCB design and assembly process.

Leave a Reply